Back to Journals » Clinical, Cosmetic and Investigational Dentistry » Volume 10

Marginal accuracy of computer-aided design- and computer-aided manufacturing-fabricated full-arch zirconia restoration

Authors Juntavee N , Sirisathit I

Received 16 October 2017

Accepted for publication 13 December 2017

Published 15 February 2018 Volume 2018:10 Pages 9—17

DOI https://doi.org/10.2147/CCIDE.S154156

Checked for plagiarism Yes

Review by Single anonymous peer review

Peer reviewer comments 3

Editor who approved publication: Professor Christopher E. Okunseri

Niwut Juntavee,1 Issarawas Sirisathit2

1Department of Prosthodontics, 2Division of Biomaterials and Prosthodontics Research, Faculty of Dentistry, Khon Kaen University, Khon Kaen, Thailand

Objective: This study evaluated marginal accuracy of full-arch zirconia restoration fabricated from two digital computer-aided design and computer-aided manufacturing (CAD-CAM) systems (Trios-3 and CS3500) in comparison to conventional cast metal restoration.

Materials and methods: A stainless steel model comprising two canine and two molar abutments was used as a master model for full-arch reconstruction. The canine and molar abutments were machined in a cylindrical shape with 5° taper and chamfer margin. The CAD-CAM systems based on the digital approach were used to construct the full-arch zirconia restoration. The conventional cast metal restoration was fabricated according to a conventional lost-wax technique using nickel–chromium alloys. Ten restorations were fabricated from each system. The marginal accuracy of each restoration was determined at four locations for each abutment. An analysis of variance (ANOVA) and Tukey’s honest significant difference (HSD) multiple comparisons were used to determine statistically significant difference at 95% confidence interval.

Results: The mean values of marginal accuracy of restorations fabricated from conventional casting, Trios-3, and CS3500 were 48.59±4.16 μm, 53.50±5.66 μm, and 56.47±5.52 μm, respectively. ANOVA indicated significant difference in marginal fit of restorations among various systems. The marginal discrepancy of zirconia restoration fabricated from the CS3500 system demonstrated significantly larger gap than that fabricated from the 3Shape system (p<0.05). Tukey’s HSD multiple comparisons indicated that the zirconia restoration fabricated from either CS3500 or Trios-3 demonstrated a significantly larger marginal gap than the conventional cast metal restoration (p<0.05).

Conclusion: Full-arch zirconia restoration fabricated from the Trios-3 illustrated better marginal fits than that from the CS3500, although, both were slightly less accurate than the conventional cast restoration. However, the marginal discrepancies of restoration produced by both CAD-CAM systems were within the clinically acceptable range and satisfactorily precise to be suggested for construction full-arch zirconia restoration.

Keywords: digital dentistry, extensive reconstruction, zirconia, marginal fit

Introduction

Dental reconstruction with fixed prostheses needs to achieve esthetic, biocompatibility, and sufficient strength for withstanding the stress of the physiological masticatory function.1,2 Patients often request metal-free restoration, which leads to ceramic being the restoration of choice for fixed prosthodontics reconstruction.3,4 The long-term success of fixed dental restoration is greatly influenced by the marginal accuracy of the restoration.5,6 Improper marginal adaptation of the restoration induces microbacteria deposits on the plaque, which initiates decay and periodontal disease and leads to failure of the restoration.7,8 Several new dental ceramics have been developed with improved strengths for withstanding masticatory function force and being used as long-span fixed dental prostheses.9–11 Among contemporary ceramic materials, yttria-stabilized tetragonal zirconia polycrystalline (Y-TZP) has recently been introduced as an alternative to metal substructure owing to its excellent esthetics, biological compatibility, less plaque accumulation, minimal thermal conductivity in addition to superior flexural strength, and fracture toughness.1,4,12 A unique characteristic of Y-TZP, on account of a transformation toughening phenomenon, has been reported to be the ability to efficiently inhibit crack propagation.2,11

The zirconia restorations can be fabricated by the process of computer-aided design and computer-aided manufacturing (CAD-CAM) technology.8,9 The zirconia milling process can be performed using either a fully sintered or partial-sintered zirconia blank. The milling of a fully sintered zirconia blank to the actual size of the restoration provides good marginal accuracy, ~60.4–74.0 μm, as the technique requires no further sintering process, thus eliminating the sintering shrinkage of zirconia.12 However, this technique causes high wear rates of the milling instrument and takes a long time.6 The other milling procedure that utilizes a partial-sintered zirconia blank is easily machinable, but it needs to be sintered further to achieve fully sintered zirconia restoration. The zirconia restoration needs to be designed in an enlarged dimension prior to the milling process in order to compensate for linear sintering shrinkage of zirconia by ~15–30%.13–15 The potential cause of improper fit of the restoration may be due to not only the sintering shrinkage but also the scanning process, software design, or the milling procedure.16

Accuracy of restoration has been proven to have an important role in the fabrication of dental restorations to provide longevity of the restoration. Precise marginal accuracy of dental restoration minimizes the likelihood of diseases associated with abutment teeth and increases long-term prognosis of restoration.7,8 It was reported that improper marginal fit of CAD-CAM-fabricated zirconia fixed partial dentures exhibited 21.7% of secondary caries after 5 years.8 Several CAD-CAM systems that have been introduced into dental practice must demonstrate that their restoration fabrication capabilities are somewhat comparable with regard to accuracy to the conventional fabrication process. It is generally accepted that fixed dental restoration should possess marginal discrepancy below 120 μm in order to be defined as clinically acceptable restoration.17 However, a minimal gap between restoration and its abutment is crucial for ensuring accuracy in conjunction with feasibility of cementation procedure. Upon insertion, in order to be properly seated into position, the restoration must have an even luting cement film thickness of ~25–50 μm at the margin.18,19 Thus, it is required for all restorations, fabricated from any system, to be evaluated for marginal accuracy to ensure clinical reliability. Marginal accuracy can be determined by several techniques, such as the direct exploration with visual examination, silicone weight, or impression replica technique, which can detect the accuracy of restoration either in vivo or in vitro.20–23 Until the present study, there has been no evidence of the reliability of zirconia restoration fabricated from partial-sintered Y-TZP material for full-arch reconstruction. The study determines the marginal accuracy of zirconia restorations generated by two CAD-CAM systems including Trios-3 (3Shape A/S, Copenhagen, Denmark) and CS3500 (Carestream Health, Rochester, NY, USA) in comparison with the conventional full-arch cast metal restoration. The hypothesis was that the full-arch zirconia restoration fabricated from either a Trios-3 or a CS3500 system demonstrated marginal accuracy comparable to the traditional full-arch cast metal restoration.

Materials and methods

Master model fabrication

A custom full-arch master model, comprising two anterior abutments representing canines and two posterior abutments representing molars, was fabricated by numerical control machining that used stainless steel (Figure 1A). The abutments were machined in a cylindrical shape, with a chamfer margin width of 1.2 mm and 1.4 mm for canines and molars, respectively, and possessed the axial surface height of 8 mm with a 5° taper leading to the total convergence angle of 10°. The chamfer margin possessed round external and internal finishing line with diameters of 7.8 mm and 6.6 mm for canine abutment and 11.0 mm and 9.6 mm for molar abutment. All abutments were positioned on the metal plate with a distance of 35 mm between the centers of right and left canines, 50 mm between the centers of right and left molars, and 30 mm between the centers of canine and molar abutments on the same side (Figure 1B). A master metal model was used for the construction of full-arch restoration, comprising two canines and two molar retainers with eight pontics.

| Figure 1 Stainless steel master model containing two anterior and two posterior abutments assembled on metal plate (A) in specific dimension (B). |

Fabrication of zirconia restoration

The full-arch zirconia restorations were fabricated from CAD-CAM systems either from a Trios-3 or a CS3500 system. Ten digital impressions of a master metal model were performed for each system by scanning with their respective intraoral scanners and transformed into standard transformation language (STL) files for fabrication resin models (Fotodent®, Dreve Dentamid GmbH, Unna, Germany) using model printing machines (ProMaker® D35, Prodways, Les Mureaux, France). Ten resin models were constructed for each system. The full-arch restorations were designed using either Trios-3 CAD software (3Shape A/S) or Ceramill®Mind CAD software (Amann Girrbach GmbH, Koblach, Austria). The digital files of the designed restorations for the Trios-3 system were transferred to a milling machine (Hint-ELs, Griesheim, Germany) for milling the partial sintered zirconia blank (Lava™ Plus; 3M ESPE, Seefeld, Germany) and further sintered in the furnace (InFire® HTC speed, Sirona GmbH, Bensheim, Germany). Based on the recommendation of a manufacturer, the firing was scheduled at 1450°C for 120 minutes of holding time. In the same manner for the CS3500 system, the digital files of the designed restorations were transferred to a milling machine (Ceramill® Motion 2; Amann Girrbach AG, Koblach, Austria) for milling the partial sintered zirconia blank (Ceramill® Zolid 71M; Amann Girrbach AG) and further sintered in the furnace (Ceramill® Therm 3; Amann Girrbach AG) based on a manufacturer-recommended firing scheduled at 1470°C for 120 minutes of holding time. After the sintering process, the restorations were finished and seated onto the resin models.

Fabrication of conventional cast restoration

The impressions of a master metal model were performed by using a medium and light viscosity silicone impression material (Siligum®, DMG, Hamburg, Germany) by a double-mixed impression technique on a special tray and then poured with dental stone type IV (Vel-Mix®, Kerr Corporation, Orange, CA, USA) in order to fabricate master casts. The die hardener (Bredent, Senden, Germany) was applied on the master cast. The die spacer (Bredent) was coated on each abutment twice. The wax pattern for the full-arch restoration was performed using blue inlay casting wax (Kerr Corporation), invested with phosphate bond investment (Formula-1®; Whip Mix, Louisville, KY, USA), and cast using non-noble metal alloy (4all®; Ivoclar Vivadent, Germany). Then, the cast restoration was finished and seated on the master stone model.

Evaluation marginal accuracy

The impression replica technique was used to determine the marginal accuracy.13 Light viscosity silicone impression material was injected into the internal surface of each restoration retainer. The restoration was then seated on the master model with 50 N load directly to the long axis of abutments for 10 minutes (Figure 2A).24 After the impression material was fully set, the restoration was removed from the master model, leaving a thin film of light body silicone adhering to each abutment on the master metal model. A medium viscosity silicone impression material was applied to pick up the light body impression material film and further stabilized by injecting the medium viscosity silicone impression material into the inner surface for stabilizing replica film as a sandwiched technique. The silicone replica was segmented with the razor blades through the center of the replica in the buccolingual and mesiodistal directions for each abutment tooth. The marginal gaps were measured at medial and lateral locations in the buccolingual and mesiodistal directions for each abutment by using a microscope equipped with a digital camera and an electronic micrometer counter (Nikon Measurescope 20 and Nikon D800 and Nikon SC-102; Nikon Instruments, Melville, NY, USA) at a 5× magnification (Figure 2B).

Statistical analysis

The data were statistically analyzed using SPSS statistical software version 17 (SPSS Inc., Chicago, IL, USA). An analysis of variance (ANOVA) was used to determine the statistically significant difference of marginal discrepancy among the investigated systems as well as the location of each system’s abutment. Post-hoc Tukey’s HSD multiple comparisons were used to determine the difference between such factors at 95% confidence interval.

Results

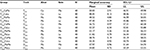

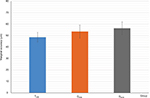

The mean and SD of marginal accuracy for full-arch restorations fabricated from zirconia by two different CAD-CAM systems in comparison to conventional cast metal restoration were reported on both the lateral and medial sides of canine and molar abutments, as shown in Figure 3 and Table 1. The mean and SD for marginal accuracy of the traditional cast metal restoration (TCM) on the lateral and medial sides were 47.40±4.29 μm and 48.52±4.80 μm, respectively, for molar abutment, while they were 45.45±4.12 μm and 50.00±2.91 μm, respectively, for the canine abutment. The mean and SD of the marginal accuracy for the zirconia restoration fabricated from the Trios-3 system (DZ3S) on the lateral and medial sides were 51.82±4.79 μm and 53.17±5.26 μm, respectively, for the molar abutment, whereas they were indicated as 52.27±6.34 μm and 56.72±4.97 μm, respectively, for the canine abutment. The mean and SD of the marginal accuracy for the zirconia restoration fabricated from the CS3500 system (DZCS) on the lateral and medial sides were 54.80±4.72 μm and 57.97±5.96 μm, respectively, for the molar abutment and 54.35±4.92 μm and 58.75±5.19 μm, respectively, for the canine abutment.

An ANOVA revealed significant differences in marginal accuracy of restoration due to the effect of the systems during fabrication, abutment tooth, and site of restorative margin (p<0.05). There were no significant differences in marginal accuracy of restoration fabrication from different fabrication systems due to the interaction between the various factors (p>0.05), as shown in Table 2.

The marginal discrepancy of zirconia restoration fabricated from the CS3500 demonstrated a significantly larger one than that fabricated from the Trios-3 (p<0.05), as shown in Figure 4. The zirconia restoration fabrication from both CS3500 and Trios-3 systems indicated a significantly larger marginal discrepancy than the conventionally fabricated cast metal restoration (p<0.05), as shown in Figure 4. The marginal discrepancies for full-arch restorations were significantly larger at the canine abutment than at the molar abutment in every tested system (p<0.05), as shown in Figure 5. The marginal discrepancies for full-arch restoration were significantly larger at the medial side of abutment than those at the lateral side of abutment in every tested system (p<0.05), as shown in Figure 6.

Discussion

In spite of careful tooth preparation and extremely controlled fabrication process for fixed dental restoration, inaccuracy still remains between the margins of the restorations and the finishing lines of the prepared abutments, which predisposes the tooth abutment to caries and periodontal disease.7,8 The more precisely the margin of the restoration adapts to the finishing line of the prepared tooth, the less the marginal gap manifests and the less the cement film is exposed to oral fluid.6 It is generally agreed that a marginal fit below 120 μm is clinically acceptable for conventional fixed dental restorations.17,18 In this study, the marginal discrepancies of full-arch restorations for both conventional cast metal restoration and CAD-CAM-fabricated zirconia restoration were <120 μm, which indicated a precise fit within the clinically acceptable range and sufficient for use in the clinical situation. The accuracy of the zirconia restoration fabricated by both CAD-CAM systems was favorably comparable with conventional cast metal restoration. However, the zirconia restoration fabricated from the Trios-3 system resulted in a better marginal accuracy than that fabricated from the CS3500 system. It can be assumed that the difference in the marginal accuracy between the systems is related to the software design of the restoration in compensation for the sintering shrinkage of zirconia in each system. Even though the zirconia restorations fabricated from both CAD-CAM systems had significant differences in marginal accuracy compared to conventional cast metal restoration, the differences are considered to be minimal. The relevance in marginal discrepancy seems to be acceptable for clinical situations, since the mean marginal discrepancy values as well as the upper boundary values were below the acceptable clinical discrepancy of 120 µm.17,18

The marginal discrepancy of full-arch cast metal restoration related to the dimensional inaccuracy of the traditional procedure in restoration fabrication (including impression procedure, dimensional inaccuracy of stone model and investment material) as well as the amount of metal shrinkage upon casting process, directly affected the restoration’s fit.25 The full-arch zirconia restoration is fabricated using the CAD-CAM technique with an intraoral scanner for performing digital impression, a three-dimensional software program for designing restoration, and a computer-controlled machine milling zirconia. The digital technique does not require conventional processes, and therefore, the dimension seems to be stable. Even though zirconia restorations must deal with the sintering shrinkage of the material, this process is compensated during the restoration design by the software. This process is considered to be the minimal unavoidable error inherent to each CAD-CAM system.16 The optical impression procedure usually produces slightly round edges depending on the resolution of each digital scanning system, which leads to premature contact of restoration at the occlusal corner and induces more marginal inaccuracy. The digital impression process also generates error peaks at the location near the edges of the object and results in an increasing marginal discrepancy.26 This phenomenon has been described to be related to every CAD-CAM system that acquires digital impression. The point clouds obtained by the digital scanning procedure are transformed into a smooth, continuous surface with the capability of software designing. This process can also lead to some inaccuracies.

The tendency to indicate larger marginal discrepancies at the canine abutment as compared to the molar abutment may be attributed to the geometry of the canine abutment, which is smaller in size. Only minimal inaccuracy upon sinter shrinkage may influence the canine more strongly than molar abutment. It is also difficult to obtain restoration fit at the canine than at the molar abutment, so the marginal discrepancies are more likely to occur at the canine abutments. The other reason may be related to the amount of restorative material adjacent to the retainer of the restoration. In this study, the canine retainers have many pontics attached to both sides: four pontics on the mesial side connecting the canine to the contralateral side and two pontics on the distal side connecting the molar retainers in the same quadrant. In contrast, the molar retainers have pontics attached only on one side – on the mesial side – of the retainer connecting the canine retainers in the same quadrant. The marginal discrepancy seems to have more effect on the retainer, with many pontics attached due to the shrinkage pattern of restoration that takes place upon the bulk of material, as supported by other studies.14,15

The marginal discrepancy exhibited a wider gap at the medial side than at the lateral side of retainer. This may be related to the shrinkage pattern of the restoration during fabrication procedure that is exhibited in three dimensions. The nature of sintering shrinkage exhibits directly toward the central part of the restoration and gives rise to inaccuracy in the medial side more than the lateral side, as supported by other studies.14,15

Since CAD-CAM-fabricated zirconia restorations are relatively new and rapidly increasing in the dental practice, the data on marginal accuracy in this study based on the standardized conditions with respect to abutment design, impression technique, and experimental performance provide reasonably valuable scientific data for clinicians for making reconstruction decisions with full-arch digitally fabricated zirconia restoration in the dental practice. Within the limitations of this study, both CAD-CAM systems were able to fabricate full-arch zirconia restoration, with extremely large restoration and satisfactorily precise marginal fit. The differences in marginal fit at each abutment and region of the retainer for both systems were within the acceptable range for full-arch zirconia restoration to be clinically utilized for extensive oral reconstruction. The study also indicates the possibility of fabricating the unambiguous full-arch zirconia restorations using partial sintered zirconia blanks. Further studies are required to evaluate the influence of digital scanning procedure and milling process on the accuracy of zirconia restoration.

Conclusion

The results of this study reject the null hypotheses that the marginal fits of full-arch fixed restoration are affected by different fabrication systems. The significant differences in the marginal fit of restorations fabricated from the two CAD-CAM systems and the traditional cast metal procedure were shown. However, the marginal discrepancies of zirconia restoration produced by the CAD-CAM systems were within clinically acceptable ranges and comparable with the conventional cast metal restoration. The differences in marginal fit in each abutment and region of the retainer were within the acceptable range for full-arch zirconia restoration in order to be clinically adopted for extensive oral reconstruction.

Clinical significance

Both Trios-3 and CS3500 CAD-CAM systems can be contemplated for fabrication of full-arch zirconia restoration with sufficient accuracy. Clinicians should be confident with using CAD-CAM systems for extensive full-arch oral reconstruction with zirconia restoration.

Disclosure

The authors do not have any financial interest with companies that have materials included, and report no conflicts of interest in this work.

References

Conrad HJ, Seong WJ, Pesun IJ. Current ceramic materials and systems with clinical recommendations: a systematic review. J Prosthet Dent. 2007;98(5):389–404. | ||

Hannink RJ, Kelly PM, Muddly BC. Transformation toughening in zirconia containing ceramics. J Am Ceram Soc. 2000;83(3):461–487. | ||

Reich S, Kappe K, Teschner H, Schmitt J. Clinical fit of four-unit zirconia posterior fixed dental prostheses. Eur J Oral Sci. 2008;116(6):579–584. | ||

Denry I, Kelly JR. Emerging ceramic-based materials for dentistry. J Dent Res. 2014;93(12):1235–1242. | ||

Bindl A, Mormann WH. Marginal and internal fit of all-ceramic CAD/CAM crown-copings on chamfer preparations. J Oral Rehabil. 2005;32(6):441–447. | ||

Tinschert J, Natt G, Mautsch W, Spiekermann H, Anusavice KJ. Marginal fit of alumina-and zirconia-based fixed partial dentures produced by a CAD/CAM system. Oper Dent. 2001;26(4):367–374. | ||

Felton DA, Kanoy BE, Bayne SC, Wirthman GP. Effect of in vivo crown margin discrepancies on periodontal health. J Prosthet Dent. 1991;65(3):357–364. | ||

Sailer I, Feher A, Filser F, Gauckler LJ, Luthy H, Hammerle CH. Five-year clinical results of zirconia frameworks for posterior fixed partial dentures. Int J Prosthodont. 2007;20(4):383–388. | ||

Tinschert J, Natt G, Mohrbotter N, Spiekermann H, Schulze KA. Lifetime of alumina- and zirconia ceramics used for crown and bridge restorations. J Biomed Mater Res B Appl Biomater. 2007;80(2):317–321. | ||

Luthardt RG, Holzhuter M, Sandkuhl O, et al. Reliability and properties of ground Y-TZP-zirconia ceramics. J Dent Res. 2002;81(7):487–491. | ||

Kohorst P, Junghanns J, Dittmer MP, Borchers L, Stiesch M. Different CAD/CAM-processing routes for zirconia restorations: influence on fitting accuracy. Clin Oral Investig. 2011;15(4):527–536. | ||

Coli P, Karlsson S. Precision of a CAD/CAM technique for the production of zirconium dioxide copings. Int J Prosthodont. 2004;17(5):577–580. | ||

Reich S, Wichmann M, Nkenke E, Proeschel P. Clinical fit of all-ceramic three-unit fixed partial dentures, generated with three different CAD/CAM systems. Eur J Oral Sci. 2005;113(2):174–179. | ||

Kokubo Y, Ohkubo C, Tsumita M, Miyashita A, Vult von Steyern P, Fukushima S. Clinical marginal and internal gaps of Procera AllCeram crowns. J Oral Rehabil. 2005;32(7):526–530. | ||

Kunii J, Hotta Y, Tamaki Y, et al. Effect of sintering on the marginal and internal fit of CAD/CAM-fabricated zirconia frameworks. Dent Mater J. 2007;26(6):820–826. | ||

Tinschert J, Natt G, Hassenpflug S, Spiekermann H. Status of current CAD/CAM technology in dental medicine. Int J Comput Dent. 2004;7(1):25–45. | ||

McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131(3):107–111. | ||

Boitelle P, Mawussi B, Tapie L, Fromentin O. A systematic review of CAD/CAM fit restoration evaluations. J Oral Rehabil. 2014;41(11):853–874. | ||

Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989;62(4):405–408. | ||

Sorensen JA. A standardized method for determination of crown margin fidelity. J Prosthet Dent. 1990;64(1):18–24. | ||

May KB, Russell MM, Razzoog ME, Lang BR. Precision of fit: the Procera AllCeram crown. J Prosthet Dent. 1998;80(4):394–404. | ||

Nakamura T, Dei N, Kojima T, Wakabayashi K. Marginal and internal fit of Cerec 3 CAD/CAM all-ceramic crowns. Int J Prosthodont. 2003;16(3):244–248. | ||

Falk A, Vult von Steyern P, Fransson H, Thoren MM. Reliability of the impression replica technique. Int J Prosthodont. 2015;28(2):179–180. | ||

Proussaefs P. Crowns cemented on crown preparations lacking geometric resistance form. Part II: effect of cement. J Prosthodont. 2004;13(1):36–41. | ||

Corso M, Abanomy A, Di Canzio J, Zurakowski D, Morgano SM. The effect of temperature changes on the dimensional stability of polyvinyl siloxane and polyether impression materials. J Prosthet Dent. 1998;79(6):626–631. | ||

Pfeiffer J. Dental CAD/CAM technologies: the optical impression (II). Int J Comput Dent. 1999;2(1):65–72. |

© 2018 The Author(s). This work is published and licensed by Dove Medical Press Limited. The full terms of this license are available at https://www.dovepress.com/terms.php and incorporate the Creative Commons Attribution - Non Commercial (unported, v3.0) License.

By accessing the work you hereby accept the Terms. Non-commercial uses of the work are permitted without any further permission from Dove Medical Press Limited, provided the work is properly attributed. For permission for commercial use of this work, please see paragraphs 4.2 and 5 of our Terms.

© 2018 The Author(s). This work is published and licensed by Dove Medical Press Limited. The full terms of this license are available at https://www.dovepress.com/terms.php and incorporate the Creative Commons Attribution - Non Commercial (unported, v3.0) License.

By accessing the work you hereby accept the Terms. Non-commercial uses of the work are permitted without any further permission from Dove Medical Press Limited, provided the work is properly attributed. For permission for commercial use of this work, please see paragraphs 4.2 and 5 of our Terms.