Back to Journals » ClinicoEconomics and Outcomes Research » Volume 14

Economic Impact Analysis of Custom Pak® on Cataract and Vitreoretinal Surgery in the United States

Authors Ayres BD , Gupta OP, Davis JS , Hahn R , Hsiao CW, Kara R, Di Simplicio S

Received 26 July 2022

Accepted for publication 28 October 2022

Published 10 November 2022 Volume 2022:14 Pages 715—730

DOI https://doi.org/10.2147/CEOR.S382188

Checked for plagiarism Yes

Review by Single anonymous peer review

Peer reviewer comments 2

Editor who approved publication: Professor Giorgio Colombo

Brandon D Ayres,1 Omesh P Gupta,2 Jonathan S Davis,3 Rebecca Hahn,3 Chia-Wen Hsiao,4 Richard Kara,4 Sandro Di Simplicio5

1Wills Eye Hospital, Philadelphia, PA, USA; 2The Retina Service of Wills Eye Institute, Thomas Jefferson University Hospital, Philadelphia, PA, USA; 3KJT Group, Inc., Rochester, NY, USA; 4Alcon Vision LLC, Fort Worth, TX, USA; 5Royal Victoria Infirmary, Newcastle Upon Tyne, UK

Correspondence: Jonathan S Davis, KJT Group, Inc, 777 Canal View Blvd, Rochester, NY, 14623, USA, Tel +1 585-269-4237, Email [email protected]

Purpose: Implicit costs of surgical preparation and materials management for cataract/anterior segment and retinal/posterior segment procedures are often unquantified. Use of ophthalmological surgical procedure packs is common in these surgeries; however, there is little in the literature demonstrating their time and cost impacts. Understanding the costs and potential benefits of surgical pack procedure use is important for administrators in purchasing decision-making. The objective of this study is to estimate the economic impact of Alcon Custom Pak® on cataract and vitreoretinal (retina) surgery in hospitals and ambulatory surgical centers (ASCs) across operating room (OR), materials management, and accounting departments.

Methods: We conducted a study in 2019 among US hospitals and ASCs using an online survey and a surgery timing exercise. Surgical technicians and supply chain managers were surveyed regarding current cataract and retina surgery practices including OR, materials management, and accounting tasks. Surgical technicians timed cataract and retina surgeries, recording activity timestamps and surgical supply use from Alcon Custom Pak and other sources. Using the survey and timing exercise inputs and literature and government sources, we developed a budget impact model (BIM) to quantify hidden costs of time and labor spent across the entire surgery supply life cycle.

Results: Representing a geographical mix of 99 facilities, surgical technicians (56 cataract/46 retina) and supply chain managers (23 cataract/24 retina) provided data for their institutions. Technicians timed 290 cataract and 250 retina surgeries. In the BIM, increasing baseline Custom Pak utilization to 100% of surgeries while also sourcing all relevant supplies from Custom Pak results in annual cost savings ranging from $92,273 to $217,675 across procedure type and setting, allowing for between 75 (retina ASC) and 266 (cataract hospital) potential additional procedures per facility/year.

Conclusion: This study demonstrates that increasing Custom Pak usage can potentially save time, reduce hidden costs, and increase throughput.

Keywords: cataract, retina, vitreoretinal surgery, surgical instruments, model, economic, hospital materials management

Introduction

Materials management and surgical preparation for cataract/anterior segment and retinal/posterior segment surgical procedures requires demanding logistics including ordering, receiving, storing, pulling, preparing, and paying for surgical supplies that carry significant time and labor costs that often go unquantified.1 Without properly measuring these implicit costs, it is challenging for hospital and ambulatory surgical center (ASC) administrators to decide how to streamline internal processes and/or make purchasing decisions. Quantifying implicit costs is particularly relevant for products and services such as surgical procedure packs that offer efficiencies in materials management and surgical preparation and/or facilitate faster surgical preparation.

Surgical procedure packs (surgical packs) are sets of disposables and sterile surgical supplies assembled and packaged for per procedure use, easing materials management and surgery preparation. Although surgical packs have been used for decades, there is little in the literature assessing the time and cost impacts to facilities,2 and analyses of surgical pack use in ophthalmological procedures are old and very limited in scope. A hidden cost calculator was developed in 1995 to demonstrate the impact of ordering items used in cataract surgery; this was exemplified in the literature with one item (angled blade) across hospital departments.1 Furthermore, an exploratory time and motion study in two French hospitals was presented in 2004 which examined cost variations of disposable supplies used in cataract surgery with and without Alcon Custom Pak® (Custom Pak), a type of surgical pack used in ophthalmological surgeries; the researchers found Custom Pak decreased surgery preparation time, resulting in substantial cost savings.3

Impact of surgical packs have been investigated in other types of procedures. A quantitative study of neurosurgical procedures demonstrated time savings from using surgical packs that translated to cost savings due to faster surgical preparation, ability to better manage stock, and reduced surgical supply deliveries.4 A multi-suture pack system for cardiac surgeries resulted in considerable time savings by operating room (OR) nurses and cost savings of up to 13% as compared to using single suture packs.5 Additionally, benefits of surgical packs have been examined in open heart surgery with significant time savings related to storage space6 and faster surgical suite turnover time and cost savings due to inventory reduction.7

It is expected that surgical packs improve surgical efficiency through faster preparation and streamlined materials management and accounting. Custom Pak provides supplies optimally arranged and customized to meet the needs of individual surgeons including both disposables and equipment-specific consumables such as BSS® (balanced salt solution), fluidics management system (FMS), viscoelastics, knives, drapes, back table covers, cannulas, backflush, eye shields, gloves, gowns, needles, sponges, and syringes. Custom Pak, the most widely used surgical pack for ophthalmological procedures in the U.S,8 was evaluated due to its comprehensive coverage of disposables and equipment-specific consumables.

To better understand the impact of surgical packs on the implicit costs of cataract and vitreoretinal (retina) surgery, we sought to assess the time spent managing or handling each supply type throughout the entire supply life cycle from negotiating prices to surgery room preparation. Timing and cost estimates were used to construct a budget impact model (BIM) of cataract and retina procedures to quantify and compare time spent preparing the OR between cases and managing supplies both with and without a surgical pack, including variation in surgical pack configuration and the extent of individual supply sourcing.

Methods

Study Design

We conducted a cross-sectional study between June 28, 2019, and August 12, 2019, to quantify the implicit time and financial costs of OR preparation, materials management, and accounting for cataract and retina surgery, using a two-pronged approach for obtaining the inputs for the economic analysis. An online survey was used to collect information about current practices from surgical technicians and supply chain managers at hospitals and ASCs (including eye care centers) in the US. The survey assessed current cataract and retina surgery practices including OR, materials management, and accounting tasks spent for commonly used surgical supplies (21 supply types for cataract and 17 supply types for retina). We evaluated time spent related to surgical supplies over the entire within-facility life cycle from negotiating prices for supplies and ordering them through receiving, stocking, pulling, and preparing them within the surgical field to the surgery start. Surgical technicians also completed a timing exercise of five surgeries, on average, at their facility. Respondents recorded specific activity timestamps for surgery preparation and the surgery itself. For each surgery, surgical technicians recorded surgical supply use from Custom Pak and other sources. The study protocol was submitted to Western Institutional Review Board (WIRB), a central institutional review board, as the research was not conducted at the authors’ affiliated institutes. WIRB prospectively reviewed the study and considered it exempt because it is an online survey with adequate protections in place to protect the privacy of subjects and to maintain the confidentiality of data. The study and data accumulation were in conformity with all country, federal, or state laws, informed consent was obtained from participants, and the study was in adherence to the tenets of the Declaration of Helsinki.

Participants

Potential study participants were recruited via telephone or email using a sponsor-supplied list of ophthalmological surgical facilities and by an online panel company to which respondents had given permission to be contacted for research purposes. Additionally, we recruited respondents via referrals from participating respondents. Respondents were required to meet all inclusion criteria: 1) currently employed at an ASC/eye center or hospital in the US, excluding Vermont and Maine to comply with Sunshine Act reporting policies; 2) holds a position of surgical technician (including titles of surgical technician, scrub technician, OR technician, OR nurse, registered nurse, or licensed practical nurse) or supply chain manager (including titles of inventory control manager or purchasing agent); 3) responsible for pulling surgical supplies (surgical technician) or ordering and managing inventory for cataract and retina surgical supplies (supply chain manager); 4) employed in current role between two and 35 years; 5) does not self-identify as employed at a government or Veterans Affairs hospital (public community hospital was a separate designation that was not an exclusion criteria); and 6) participates in a minimum of 30 cataract or 20 retina procedures per month (surgical technician). Surgical technicians and supply chain managers who qualified for both the cataract and retina sections of the survey completed the survey for both surgery types.

Budget Impact Model

Together with information from the literature and publicly available data, the survey and timing exercise inputs were used to develop a BIM to estimate time spent and labor costs of surgery preparation, materials management, and accounting. We determined time and costs for a representative hospital or ASC specified by reported means, aggregated across three facility departments (OR, Materials Management, and Accounting). For each supply type, the model uses the mean time spent for tasks in the supply’s life cycle to calculate total time expenditures with and without surgical pack use. Per procedure and per year total direct time expenditures were calculated separately for each department and at the facility level.

Variables and Measurements

Model inputs and sources are described in Table 1. Prior to fielding the survey, we pilot tested the instrument and timing exercise to evaluate their face validity. Pretest interviews were conducted via telephone and a web-based platform among two surgical technicians and two supply chain managers. Minor wording changes were made to the survey based on feedback from the pilot to improve clarity and relevance. We found some inputs of interest were too specific for respondents to answer directly. To address this complexity and reduce cognitive burden for respondents, we instead asked several direct questions regarding available information that would allow us to calculate the necessary inputs. Duration of OR surgery preparation (everything that takes place between one surgery’s end and the beginning of the next surgery) and surgery procedures (time from when the patient enters the OR until the patient leaves the OR) were calculated from the start and end timestamps documented in the timing exercise.

|

Table 1 Cataract and Vitreoretinal Surgery Budget Impact Model Inputs |

Model Overview

An overview of the model structure is presented in Figure 1. All results are shown in per procedure and per year terms.

Time Estimates

The time required for each task (ie, price negotiation, placing orders, receiving supplies, stocking supplies, verifying invoices, paying invoices, pulling supplies, and opening supplies) and for each supply type was recorded from the survey and timing exercises of hospitals and ASCs in the US. The number of orders was calculated as follows:

Surgeries with Custom Pak add the times required for Custom Pak itself to the times required for supplies sourced individually (if any). Surgeries without Custom Pak add up all the times required for all supplies when they are sourced individually.

Cost Estimates

Costs for procedures with and without Custom Pak were estimated by multiplying time totals per minute for each task by the national median wage per minute for personnel responsible for that task (or the cost of storage or freight as appropriate):

Procedures using Custom Pak were aggregated with procedures not using Custom Pak (if any) to calculate annual totals for each task. Annual task totals were assigned to their respective departments (OR, Materials Management, and Accounting) to get department totals and facility level results. Per procedure time and cost estimates are averages taken over all surgeries at the facility (ie, total divided by annual number of surgeries). Inflation adjustments (Bureau of Labor Statistics) were made to bring all wage and cost data to be in July 2019 US dollars (USD).

Time and Cost Impact Usage Scenarios

Custom Pak is designed to include all surgical supplies for the procedure. While all the items are ordered and shipped together as part of the Custom Pak, some surgical supplies may be in separate packaging; thus, these supplies do not confer time or cost savings when stocking, storing, pulling, or opening them. These items are often referred to as “add-after” supplies because they are not wrapped in the main Custom Pak but are part of a single order and invoice. Add-after supply types include BSS 500 mL, FMS Cassette (retina), FMS Phaco Cassette (cataract), and viscoelastic supplies (cataract).

We generated budget impact analyses to estimate time and cost impacts for three different usage scenarios as described in Table 2. We evaluated two comparisons from the usage scenarios to determine the time and cost impacts following the same general formula:

|

Table 2 Budget Impact Model Usage Scenarios |

The specific applications discussed in this paper are as follows:

Total surgery preparation time impact is defined as the difference between the total time per year spent on surgery preparation in the future scenario and the corresponding time spent in the prior scenario. Per procedure surgery preparation time is defined as the average surgery preparation time multiplied by the proportion of surgery preparation time used for tasks other than opening and preparing surgical supplies plus the time spent opening and preparing the pack plus the time spent opening and preparing surgical supplies not included in the pack’s configuration:

“Potential Additional Procedures” is the amount of time saved in surgery preparation divided by the typical amount of time to prepare and complete a surgery (ie, the time between when preparation of the OR starts and when the patient leaves the OR after their procedure). To account for outliers in the raw data and the potential for self-report bias to overestimate time and cost estimates when responding to the survey, we used winsorizing to process the data – this involves replacing the extreme values of the data set with a chosen percentile value that is less extreme and reflects a reasonable threshold based on the method of data collection and/or knowledge of the population distribution. We chose to winsorize above the 80th percentile; since the highest times and costs are what were replaced in the raw data, the model results are a more conservative estimate of the impact.

Sensitivity Analyses

To further validate the budget impact model, we ran sensitivity analyses on the surgery utilization rate of Custom Pak and the configuration of Custom Pak. These analyses demonstrate the range of possible outcomes when varying only the surgery utilization rate and only supply type sourcing, respectively, holding all other variables constant. Both analyses compare the Baseline Usage Scenario to a modified version of the Full Utilization Scenario and record the impact for cataract and retina surgeries independently. For the surgery utilization analysis, we incrementally varied the percentage of surgeries using Custom Pak from 0% to 100% and recorded the impact for each 1% increase relative to Baseline Usage. For the configuration analysis, we added an additional supply type to Custom Pak, ranging from no supply types to all supply types available for that surgery relative to Baseline Usage. We also ran a sensitivity analysis on the cost of OR time, varying the cost (USD) per hour incrementally from −50% to +50% relative to Baseline Usage. To account for variability in organizational sizes and settings, additional sensitivity analyses were conducted including varying the staff (job title and corresponding salary) assigned to complete a given task (eg, opening/preparing supplies, paying invoices, receiving supplies, stocking supplies) and varying the number of personnel assigned to complete each task.

Results

Sample Characteristics

Representing 99 facilities, 56 surgical technicians and 23 supply chain managers completed the survey for cataract surgeries; 46 surgical technicians and 24 supply chain managers completed the survey regarding retina procedures. No respondents were excluded due to missing data. Technicians timed 290 cataract surgeries and 250 retina surgeries. We categorized respondents as a Custom Pak user or non-Custom Pak user based on self-reported usage of Custom Pak at their facility. See Table 3 for the respondent characteristics.

|

Table 3 Characteristics of the Study Population (N=109) |

Baseline Custom Pak Utilization

The representative hospital (based on mean reported data) performed 1062 cataract surgeries annually and used Custom Pak in 49% of surgeries; the representative ASC performed 1751 surgeries annually and used Custom Pak in 69% of surgeries. For retina surgeries, the representative hospital and ASC conducted 675 and 945 procedures annually and used Custom Pak in 53% and 56% of surgeries, respectively. Average total facility time spent per procedure ranged from 37 minutes in the ASC setting to 59 minutes in the hospital setting for cataract procedures and from 81 minutes to 93 minutes, respectively, for retina procedures (Table S1). For cataract surgeries, the average hidden cost per procedure for the representative facility was $477.26 in the ASC and $929.26 in the hospital; for retina surgeries the per procedure cost ranged from $1087.31 to $1947.30, in the ASC and hospital, respectively (Table S1).

Full Custom Pak Utilization

Using Custom Pak in all cataract surgeries to source all supplies used in surgeries (Full Utilization) in the hospital setting saves 22.8 minutes per procedure, 7.9 of which are from surgery preparation, or 140.3 preparation hours annually. Of the 7.1 minutes per procedure saved with full utilization in the ASC setting, 2.6 minutes are from surgery preparation, which amounts to 76.6 preparation hours per year. Full use of Custom Pak to source all retina hospital surgery supplies saves 20.5 minutes per procedure, 8.3 minutes of which are for surgery preparation leading to 92.8 preparation hours annually. Full (100%) utilization in the ASC setting saves 12.2 minutes per retina surgery, 5.1 accounted for by surgery preparation amounting to 80.7 preparation hours on a yearly basis.

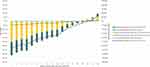

Increasing Custom Pak use in the hospital from 49% to 100% of all 1062 cataract surgeries and sourcing all surgical supplies from the Custom Pak (Full Utilization) results in per procedure implicit cost savings of $186.10 for the OR, $18.55 for materials management, and $0.32 for accounting. Increasing use in the ASC from 69% to all 1751 cataract surgeries results in per procedure hidden costs savings for the OR of $46.01, materials management of $6.93, and accounting of $0.08. Maximizing hospital Custom Pak use (100%) for retina surgeries from 53% to all 675 surgeries saves $214.43, $14.86, and $0.16 in OR, materials management, and accounting costs, per procedure, respectively. Raising Custom Pak use in the ASC from 56% to all 945 retina surgeries saves $83.26, $14.24, and $0.14 per procedure for the respective departments. Annual departmental time and hidden cost of full Custom Pak utilization and the incremental savings compared to baseline Custom Pak usage are presented in Table 4 for the hospital setting and Table 5 for the ASC setting. Potential Additional Procedures resulting from the annual surgery preparation time savings (OR department) are displayed in Figure 2.

|

Table 4 Annual Potential Time and Cost Savings from Full Custom Pak Utilization in the Hospital Setting |

|

Table 5 Annual Potential Time and Cost Savings from Full Custom Pak Utilization in the ASC Setting |

Generic Commodity Pack Sourcing

Some generic commodity surgical packs offer only “pure disposables”, which include only supplies such as back table cover, bowls, cannulas, cups, drapes, eye shields, gloves, gowns, needles, sponges, syringes, and trays. Generic commodity surgical packs for cataract surgery also include cystitomes and knives; retina generic commodity surgical packs also include soft tip cannulas. Comprehensive packs include pure disposables and equipment-specific disposables that are part of Custom Pak for cataract surgery which include I/A handpiece, irrigation sleeves, viscoelastic, phaco tips, BSS/BSS Plus 500 mL, BSS 15 mL, and the FMS/Phaco cassette; for retina surgery, these supplies include BSS/BSS Plus 500 mL, BSS 15 mL, and FMS. Shifting from the “Generic Commodity Pack” scenario to the “Full Utilization” scenario (Equipment and Generic Commodity Pack Disposables Impact) results in annual cost savings for cataract procedures ranging from $48,102.12 in the ASC setting to $52,010.71 in the hospital setting (Table 6). Annual cost savings for retina procedures ranged from $10,795.52 in an ASC to $12,793.39 in a hospital (Table 6).

|

Table 6 Annual Time and Cost Savings of Including Equipment-Specific Supplies with Generic Commodity Pack Disposables |

At the time the study was conducted, the FMS and FMS/Phaco cassette were add-afters for Custom Pak; they are also the most time-consuming individual supplies to prepare in the OR. If these supplies were incorporated into the Custom Pak itself (ie, no longer an add-after), the annual savings from shifting to the “Full Utilization” scenario would increase to $77,545.09 and $78,319.07 for cataract surgeries in the ASC and hospital setting respectively; for retina procedures, the increased savings would range from $30,122.76 in the hospital to $34,887.04 in an ASC.

Sensitivity Analyses

Table 7 summarizes the results of the surgery utilization rate of Custom Pak and configuration (supply type sourcing) sensitivity analyses by identifying the “break-even” points to realize time and cost savings from Custom Pak by surgery and facility type. Holding percent of surgeries using Custom Pak to their Baseline Scenario levels, hospitals sourcing at least 12 types of supplies through Custom Pak see positive savings for both cataract and retina surgeries. ASCs have positive savings with at least 17 or 13 types of supplies sourced from Custom Pak for cataract or retina surgeries, respectively.

|

Table 7 Surgery Utilization/Configuration Necessary to Realize Time/Cost Benefits from Custom Pak Relative to Baseline Scenario |

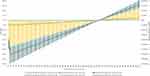

The full range of results for the surgery utilization rate sensitivity analysis is shown for cataract surgery in ASCs within Figure 3 (see Figure S1–S3 for sensitivity analysis results for cataract surgery in the hospital setting as well as retina surgery in both the ASC and hospital settings). Both axes measure savings, so negative values indicate an increase in overall hours needed or labor costs incurred. For ASCs, the minimum savings in time and labor costs for the OR and materials management occur at 0% utilization and the maximum occurs at 100% utilization. Materials management labor hours vary from requiring 268.9 additional hours at 1% utilization to saving 126.0 hours at 100% utilization. These time savings equate to increasing hidden costs by $25,848.73 versus saving $12,141.66, respectively. OR savings vary from 167.9 additional hours at 1% utilization ($176,688.12 of increased hidden costs) to 76.6 hours saved at 100% utilization ($80,555.54 of hidden cost reductions). Time and hidden cost impacts for the accounting department range from an additional 10.6 hours and $301.19 incurred (0% utilization) to maximum savings of 4.8 hours and $135.39 (100% utilization).

Figure 4 displays the configuration sensitivity results for cataract surgery in ASCs at the annual level (see Figure S4–S6 for sensitivity analysis results for cataract surgery in the hospital setting as well as retina surgery in both the ASC and hospital settings). Sourcing only one supply type within Custom Pak substantially increases labor hours equating to hidden cost increases of $24,083.37, $309.97, and $163,550.48 for materials management, accounting, and the OR, respectively. Savings of $12,167.45 are realized at the “at least break-even” point. A pack sourcing everything from Custom Pak provides the maximum savings which are the same as those found in the surgery utilization sensitivity analysis results.

Because OR costs comprise the majority of cataract and retinal procedure costs in both hospital and ASC settings, we explored the impact of varying the OR cost from −50% to +50% (USD/hour). Halving the OR costs still results in substantial annual cost savings in the hospital setting ranging from $85,581.77 (retina) to $123,504.32 (cataract); cost savings in the ASC setting range from $55,093.15 (cataract) to $55,608.65 (retina) (Figure S7–S10).

Discussion

With the ever-increasing demand for improved efficiency and cost savings in healthcare, it is important that administrators understand the value of the products they are purchasing to make decisions for their facility, healthcare providers, and patients. We hypothesized that increased surgical pack use in cataract and vitreoretinal surgery would lead to increased efficiencies in both hospital and ASC settings. Our research adds to the very narrow body of quantitative literature examining the time and cost impact of using surgical packs; previous research has been generally limited to research conducted at a single site4,5,7 and to custom packs with disposable items only.2,4–7

We aimed to quantify the impact ophthalmological surgical packs can have at the facility and department level by measuring the inherently hidden costs incurred from surgical supply management and preparation in cataract and retina surgeries. Full utilization of Custom Pak effectively eliminates the time needed to monitor supply types at each facility and potentially frees up accounting personnel and supply chain managers’ time to be put to other productive uses. Time savings from faster surgical preparation are substantial: if all time savings were efficiently used to perform additional procedures, they would allow over 250 additional cataract or almost 100 additional retina procedures per year in hospitals. Alternatively, surgical technicians’ and clinicians’ time can potentially be reallocated to other priorities. Our analysis demonstrated potential hidden cost savings of full Custom Pak use ranging from approximately $92,000 to over $217,000 across surgical settings.

We explored the impact of switching from a surgical pack containing supplies considered to be “pure disposables” to one configured with additional equipment-specific disposables that are included in Custom Pak. Configuring custom packs with both types of supplies provides considerable time and hidden cost savings for hospitals and ASCs performing cataract and retina surgeries, ranging from 26 to 122 hours saved annually, or from approximately $10,800 to approximately $52,000. Since this scenario assumed no change in the number of surgeries using Custom Pak, these results suggest that hospitals and ASCs can gain considerable time and hidden cost savings simply by consolidating their surgical supply sourcing.

One of the key strengths of our research is its comprehensive methodology to address breadth–the number of supply types covered, and depth–the ability to identify the impact of each individual supply and task. Our methodology is similar to the French Custom Pak research;3 however, by using a self-reported data collection approach, we were able to evaluate a large number of facilities in which ophthalmological procedures are typically performed. The wide geographic range of our study allowed for greater generalizability than a traditional time and motion study with a team of observers in a small number of locations. Additionally, we used data from a variety of vitreoretinal diseases to inform our assessments in the model. Furthermore, the comprehensive surgical supply coverage of Custom Pak maximized the model’s flexibility and applicability by examining the full range of surgical supply sourcing scenarios from individual supplies to custom packs. To our knowledge, this BIM is the most detailed accounting of the life cycle of cataract and retina surgical supplies to date by capturing all tasks from price negotiation and ordering to pulling and preparing supplies for surgery.

The sensitivity analyses demonstrate that the BIM is robust to changes in both surgery utilization rate and Custom Pak configuration. The Baseline Utilization Scenario’s utilization rate and configuration (both the average observed across all facilities) is sufficiently high to confer benefits within the model, indicating “real-world” robustness. Additionally, the analyses reveal that the benefits of Custom Pak usage are not unconditional: using Custom Pak in too few surgeries or sourcing too few supply types from Custom Pak can each independently incur increased labor time and hidden costs; this is due to the inherent time needed to manage and use the Custom Pak surpassing the reductions in time spent from no longer needing to source supply types individually. The results also confirm that maximum time and hidden cost savings are achieved by using Custom Pak in every surgery while sourcing all necessary supplies through the pack. The flexibility of Custom Pak can allow differences in supply types by surgeon while also enabling administrative professionals to standardize supply sourcing across surgeons conducting cataract/retina surgeries.

The surgery utilization analysis can also be interpreted as a timeline to benefits: facilities adopting Custom Pak for the first time should expect to see benefits accrue only after a significant portion of their procedures have used Custom Pak, the threshold for which depends on their current usage (between 36% of procedures and 69% of procedures based on the data from our primary research). Additionally, we found that even while assuming that hourly OR costs were half of that observed in our research, hidden cost savings were still realized, demonstrating the generalizability of the model to healthcare facilities and health systems with a wide range of OR overhead costs, potentially including those outside the US.

This research is limited to Custom Pak and the experiences of participating facilities and thus there may be some variations in protocols at other facilities conducting cataract and retina surgery in the US. Sample methodology was not random, thus potentially introducing self-selection bias and/or sample selection bias. The respondents who participated (or their institutions) may look different due to time restraints, institutional policies, or other factors. The data used in this research was self-reported, which is less reliable than third-party observation; however, the activity timestamps collected in the timing exercise were used to calculate duration of surgical preparation and of the procedure itself rather than relying on respondent recall, which improves reliability. Although the survey instrument was assessed for face validity, it was not validated. Winsorizing helps to address concerns about reliability due to self-reporting of the collected data; this method controls for outliers but reduces variation in the data. However, such a technique is likely to make our savings estimates more conservative than reality (ie, more likely to underestimate than overestimate).

We needed to make several assumptions including 1) Custom Pak is adequately represented by the average configuration and timing estimates across all Custom Pak measures; 2) Custom Pak did not include supplies that were not used during surgery (ie, we only captured the supplies that were used); 3) Custom Pak timing estimates do not change as more supplies are added to the pack; and 4) the number of orders of Custom Pak does not increase with increased Custom Pak usage–increased usage is reflected in larger orders rather than more orders (ie, the number of orders remains constant, but the number of Custom Paks in each order increases). At the time the study was conducted, the FMS and FMS/Phaco cassette were add-after supplies; however, these are currently ordered and shipped with the core Custom Pak. Thus, the current Custom Pak configuration may potentially be more efficient.

Potential Additional Surgeries estimates assume all OR preparation time savings are efficiently used for additional procedures and does not try to account for patients’ demand for surgeries. Variations in the number and type of personnel responsible for tasks accounted for in the BIM may differ in other countries; however, we conducted sensitivity analyses assessing the incremental impact of changes to these variables and found no appreciable differences in impact. Additional variations may exist if the departmental processes or tasks needed to procure, manage, and use surgical supplies for cataract/retina surgery are dissimilar to those we see in the US. Generalizability will also be limited to the extent that the amounts of each surgical supply in each cataract/vitreoretinal surgery typically used in the US differs in other regions or if the time recorded in the US setting does not reflect the situation in other countries with regards to worker productivity, education/training requirements, quality of surgical technology, or culture related to speed/procedure volume. Future areas of research could include examining Custom Pak in other countries and comparative studies of surgical packs from other manufacturers.

Further, environmental impacts of surgical packs were not measured in this study, but we believe this is a topic which needs to be investigated in future research as soon as widespread data become available. Previous research18–20 has shown that there are substantial environmental impacts of cataract surgery. Although not evaluated in this study, efficiencies gained by using Custom Pak may potentially reduce environmental impacts such as reducing waste (by only including the items required by the surgeon for that procedure) and reducing the number of shipments which may lower the carbon footprint. At the time of this publication, there is at least one public hospital in Europe trying to achieve carbon neutrality for all their cataract procedures, primarily by streamlining procurement of consumables, using comprehensive surgical packs, and recycling of materials (S. Di Simplicio, personal communication, October 2021.)

Conclusion

Custom Pak use is associated with substantial time and cost savings, particularly with full utilization at the facility level. These savings improve both cataract and retina surgical efficiency through faster surgery preparation and streamlined materials management in hospitals and ASCs, thus reducing hidden costs. These OR time savings can be leveraged for potential additional procedures thereby reducing wait times and increasing throughput.

Abbreviations

ASC, ambulatory surgical center; BIM, budget impact model; CPI; consumer price index; OR, operating room; SD; standard deviation; US, United States; USD, United States dollar.

Data Sharing Statement

The datasets generated and/or analyzed during the current study are not publicly available due to the proprietary and confidential nature of the data, but the models and methodology can be obtained from the corresponding author.

Ethics Approval and Consent to Participate

Western Institutional Review Board prospectively reviewed the study and considered it exempt because it is an online survey with adequate protections in place to protect the privacy of subjects and to maintain the confidentiality of data. The study and data accumulation were in conformity with all country, federal, or state laws, informed consent was obtained from participants, and the study was in adherence to the tenets of the Declaration of Helsinki.

Author Contributions

JSD made substantial contribution to the conception and design of the work. JSD made substantial contribution to the acquisition of data. JSD was primarily responsible for the statistical analysis of the data. JSD and RH were primarily responsible for drafting the manuscript. BDA, OPG, CH, RK, and SDS substantially revised or critically reviewed the manuscript. All authors made a significant contribution to the work reported, whether that is in the conception, study design, execution, acquisition of data, analysis and interpretation, or in all these areas; took part in drafting, revising or critically reviewing the article; gave final approval of the version to be published; have agreed on the journal to which the article has been submitted; and agree to be accountable for all aspects of the work.

Funding

This study was supported by Alcon Vision LLC, which had a role in the study design, data collection, analysis, and interpretation of data; Alcon also funded the medical writing support provided by KJT Group, Inc.

Disclosure

BDA is a consultant for Alcon, Allergan, Bausch and Lomb, Carl Zeiss Meditec, and Omeros. OPG is a consultant for Alcon. SDS is a consultant for Alcon. RH is an employee of KJT Group, Inc. which was contracted by Alcon to conduct the study and provide medical writing support. At the time this study was conducted and the manuscript was written, JSD was an employee of KJT Group, Inc. CWH and RK are employees of Alcon, the sponsor of this research. The authors report no other conflicts of interest in this work.

References

1. Harmer BA. The hidden cost calculator: a new way to look at custom packs. Mater Manag Health Care. 1995;4(7):18–19.

2. Gellman C. OR procedure packs. A cost-saving approach. Aorn J. 1988;48(1):72–75. doi:10.1016/s0001-2092(07)67441-9

3. Lafuma A, Smith AF. PES13 A cost minimisation analysis of custom pak®for cataract surgery. Value Health. 2004;7(6):749. doi:10.1016/S1098-3015(10)65990-6

4. Baines R, Colquhoun G, Jones N, Bateman R. The benefits of using customized procedure packs. Br J Perioper Nurs. 2001;11(1):34–39. doi:10.1177/175045890101100105

5. Kirk NJ. Customized suture packs. A method for containing costs. Aorn J. 1986;43(3):658–663. doi:10.1016/s0001-2092(07)65036-4

6. Rusynko BS, Schall B. Custom open heart packs. Evaluating their use in the OR. Aorn J. 1984;40(3):379–384. doi:10.1016/s0001-2092(07)65375-7

7. Kinney GJ, Lutjens LR. Cost accountability in the OR. A case for custom-designed, procedure-ready packs. Aorn J. 1986;43(6):1310. doi:10.1016/s0001-2092(07)65160-6

8. Market Scope. Single-use ophthalmic surgical products market report: a global analysis for 2019 to 2025; 2020.

9. Physician Fee Schedule Search Tool. Centers for medicare and medicaid services; Available from: https://www.cms.gov/apps/physician-feeschedule/overview.aspx.

10. Childers CP, Maggard-Gibbons M. Understanding costs of care in the operating room. JAMA Surg. 2018;153(4):e176233. doi:10.1001/jamasurg.2017.6233

11. Wage and Hour Division. Handy reference guide to the fair labor standards act. U.S. Department of Labor; 2020. Available from: https://www.dol.gov/agencies/whd/compliance-assistance/handy-reference-guide-flsa.

12. Bureau of Labor Statistics. Purchasing managers, buyers, and purchasing agents. Occupational Outlook Handbook. U.S Department of Labor; 2020. Available from: https://www.bls.gov/ooh/business-and-financial/purchasing-managers-buyers-and-purchasing-agents.htm.

13. Bureau of Labor Statistics. CPI for all urban consumers: hospital services in U.S. city average, all urban. Consumer Price Index (CPI) Databases. U.S Department of Labor; Available from: https://beta.bls.gov/dataViewer/view/timeseries/CUUR0000SEMD01.

14. Bureau of Labor Statistics. Occupational employment and wages, May 2019: 43-3061 procurement clerks. Occupational Employment Statistics. U.S Department of Labor; 2020. Available from: https://www.bls.gov/oes/2019/may/oes433061.htm.

15. Bureau of Labor Statistics. Occupational employment and wages, May 2019: 43-5071 shipping, receiving, and inventory clerks. Occupational Employment Statistics. U.S Department of Labor; Available from: https://www.bls.gov/oes/2019/may/oes435071.htm.

16. Bureau of Labor Statistics. Bookkeeping, accounting, and auditing clerks. Occupational Outlook Handbook. U.S Department of Labor; 2020. Available from: https://www.bls.gov/ooh/office-and-administrative-support/bookkeeping-accounting-and-auditing-clerks.htm.

17. Bureau of Labor Statistics. Surgical technologists. Occupational Outlook Handbook. U.S Department of Labor; 2020. Available from: https://www.bls.gov/ooh/healthcare/surgical-technologists.htm.

18. Somner J, Scott K, Morris D, Gaskell A, Shepherd I. Ophthalmology carbon footprint: something to be considered? J Cataract Refract Surg. 2009;35(1):202–203. doi:10.1016/j.jcrs.2008.09.026

19. Morris DS, Wright T, Somner JEA, Connor A. The carbon footprint of cataract surgery. Eye. 2013;27(4):495–501. doi:10.1038/eye.2013.9

20. The Royal College of Ophthalmologists. The way forward: options to help meet demand for the current and future care of eye disease; 2018. Available from: https://www.rcophth.ac.uk/wp-content/uploads/2015/10/RCOphth-The-Way-Forward-Cataract-300117.pdf.

© 2022 The Author(s). This work is published and licensed by Dove Medical Press Limited. The

full terms of this license are available at https://www.dovepress.com/terms.php

and incorporate the Creative Commons Attribution

- Non Commercial (unported, v3.0) License.

By accessing the work you hereby accept the Terms. Non-commercial uses of the work are permitted

without any further permission from Dove Medical Press Limited, provided the work is properly

attributed. For permission for commercial use of this work, please see paragraphs 4.2 and 5 of our Terms.

© 2022 The Author(s). This work is published and licensed by Dove Medical Press Limited. The

full terms of this license are available at https://www.dovepress.com/terms.php

and incorporate the Creative Commons Attribution

- Non Commercial (unported, v3.0) License.

By accessing the work you hereby accept the Terms. Non-commercial uses of the work are permitted

without any further permission from Dove Medical Press Limited, provided the work is properly

attributed. For permission for commercial use of this work, please see paragraphs 4.2 and 5 of our Terms.

Recommended articles

Comprehensive Custom-Pak® in Cataract and Vitreoretinal Surgery in Canadian Hospitals: Time and Budget Impact Analysis

Punch D, Davis JS, Hahn R, Gill R, Hsiao CW, Kara R

ClinicoEconomics and Outcomes Research 2023, 15:151-164

Published Date: 1 March 2023