Back to Journals » International Journal of Nanomedicine » Volume 18

Research Progress of Design Drugs and Composite Biomaterials in Bone Tissue Engineering

Authors Guo X , Song P, Li F, Yan Q, Bai Y, He J, Che Q, Cao H, Guo J, Su Z

Received 4 April 2023

Accepted for publication 13 June 2023

Published 1 July 2023 Volume 2023:18 Pages 3595—3622

DOI https://doi.org/10.2147/IJN.S415666

Checked for plagiarism Yes

Review by Single anonymous peer review

Peer reviewer comments 4

Editor who approved publication: Prof. Dr. Dongwoo Khang

Xinghua Guo,1,2,* Pan Song,1,2,* Feng Li,1,2,* Qihao Yan,1,2,* Yan Bai,3 Jincan He,3 Qishi Che,4 Hua Cao,5 Jiao Guo,2 Zhengquan Su1

1Guangdong Engineering Research Center of Natural Products and New Drugs, Guangdong Provincial University Engineering Technology Research Center of Natural Products and Drugs, Guangdong Pharmaceutical University, Guangzhou, 510006, People’s Republic of China; 2Guangdong Metabolic Disease Research Center of Integrated Chinese and Western Medicine, Key Laboratory of Glucolipid Metabolic Disorder, Ministry of Education of China, Guangdong TCM Key Laboratory for Metabolic Diseases, Guangdong Pharmaceutical University, Guangzhou, 510006, People’s Republic of China; 3School of Public Health, Guangdong Pharmaceutical University, Guangzhou, 510310, People’s Republic of China; 4Guangzhou Rainhome Pharm & Tech Co., Ltd, Science City, Guangzhou, 510663, People’s Republic of China; 5School of Chemistry and Chemical Engineering, Guangdong Pharmaceutical University, Zhongshan, 528458, People’s Republic of China

*These authors contributed equally to this work

Correspondence: Zhengquan Su, Guangdong Engineering Research Center of Natural Products and New Drugs, Guangdong Pharmaceutical University, Guangzhou, 510006, People’s Republic of China, Tel +86-20-3935-2067, Fax +86-20-3935-2067, Email [email protected]

Abstract: Bone, like most organs, has the ability to heal naturally and can be repaired slowly when it is slightly injured. However, in the case of bone defects caused by diseases or large shocks, surgical intervention and treatment of bone substitutes are needed, and drugs are actively matched to promote osteogenesis or prevent infection. Oral administration or injection for systemic therapy is a common way of administration in clinic, although it is not suitable for the long treatment cycle of bone tissue, and the drugs cannot exert the greatest effect or even produce toxic and side effects. In order to solve this problem, the structure or carrier simulating natural bone tissue is constructed to control the loading or release of the preparation with osteogenic potential, thus accelerating the repair of bone defect. Bioactive materials provide potential advantages for bone tissue regeneration, such as physical support, cell coverage and growth factors. In this review, we discuss the application of bone scaffolds with different structural characteristics made of polymers, ceramics and other composite materials in bone regeneration engineering and drug release, and look forward to its prospect.

Keywords: bone scaffold, drug loading, slow release, osteogenesis, biomaterial

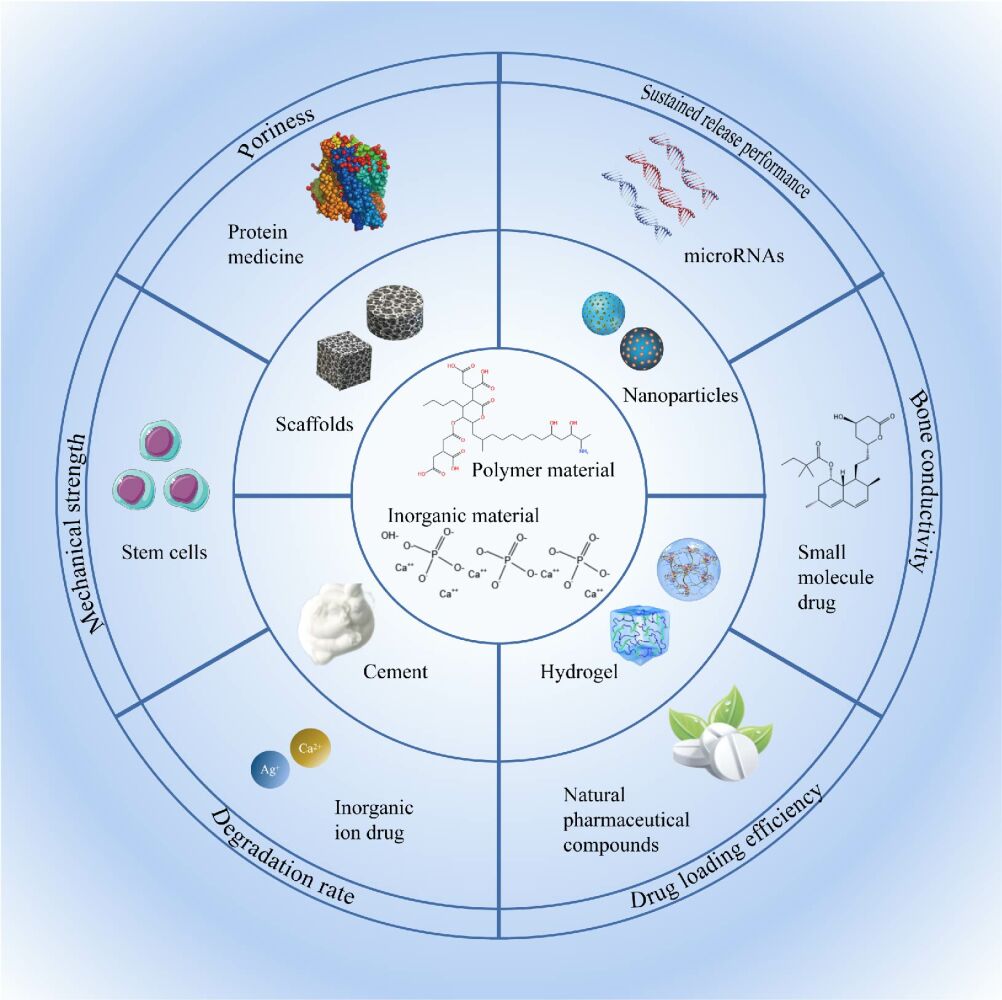

Graphical Abstract:

Introduction

Bones are a crucial organ in the human body and provide structural support to facilitate exercise and protect the body’s other organs. Bone acts as an important mineral warehouse in the human body that contains a large amount of calcium, phosphorus and other minerals, from which the internal electrolyte level of the human body can be regulated. Additionally, red bone marrow contained in bone is critical to the supply of red blood cells.1,2 Like most organs, bone tissue cells maintain homeostasis in constant proliferation and apoptosis. However, when encountering severe trauma, malignant tumor, infection and other reasons, the dynamic balance of bone repair will tilt to the bad direction. Every year there are many accidents involving bone caused by traffic accidents, sports, and large-scale machine work. Nearly 50% of people over 50 years old have a bone disease or related disease.3 Approximately 500,000 patients undergo bone transplants each year in the United States and many more globally.4 Allogenic, xenogenic and artificial bone transplantation are the most commonly used methods of treatment or repair in clinical practice. Autologous bone grafting is considered the “gold standard” because of the absence of immune response and infection issues during tissue growth. However, patients need to be further injured to obtain materials and must endure long-term postoperative pain.5 The use of allogeneic or xenogenic bone also needs careful consideration. Although this type of bone has strong bone conductivity and a similar structure, it is difficult to apply due to inflammation, immune response, infectious diseases and other reasons, which also makes the failure rate of allogeneic or xenogeneic bone transplantation higher than that of autologous bone transplantation.6,7 The main components of bone tissue include inorganic phase and organic phase. The inorganic phase is mainly calcium phosphate-based material, accounting for about 65% of bone tissue, while the organic component is type I collagen, accounting for 30%.8,9 Biological bone substitute materials are screened out according to the composition characteristics of natural bone, and are safe and non-toxic, rarely produce immune response to the human body, and their materials are relatively cheap and easy to obtain. Because of this, the use of biological bone substitute materials for treatment has become increasingly popular.

The repair of fractures caused by various unfavorable factors is usually divided into four stages: (1) Hematoma and inflammation; (2) Formation of cartilage callus; (3) The formation of hard bone callus; (4) Bone remodeling.10,11 Blood vessels in the bone and surrounding soft tissue rupture, bleed, form a hematoma, and are accompanied by an inflammatory response. The hematoma was slowly absorbed by macrophages and disappeared. Osteoclasts in the periosteum divide and proliferate and begin to clean up locally produced tissue fragments. While cleaning up the local tissue fragments of the fracture, osteoblasts, fibroblasts and capillaries on the periosteum gradually grow into the damaged bone tissue to form fibrous callus. Osteoblasts in fibrous callus secrete bone matrix to form bony callus. After the formation of bone callus, bone blood cavity gradually formed, bone callus began to calcification, bone mineral density began to recover. (Figure 1) Bone is a dynamic organ that requires living cells (osteoblasts, osteoclasts and osteocytes), sufficient blood supply, stable structure, and growth factors and growth matrix to maintain homeostasis. Therefore, ideal bone substitutes should be combined with key biological characteristics of bone, including conductivity, induction and integration. Bone substitutes have a 3D structure similar to real bone and are suitable for the ingrowth of cells and blood vessels. In addition, bone substitute materials should also have good biocompatibility and biodegradability.12,13 Notably, to improve bone formation and enhance the performance of bone substitutes, implants are typically combined with a variety of drugs with osteogenic potential, growth factors, metal ions or cells.4,11 However, there are still some challenges before this strategy is accepted for clinical treatment. For example, after adding drugs, the physical properties of the scaffold are affected, the activity of the encapsulated protein is degraded, and the drug loading and release do not reach the expected effect. The combination of different therapeutic factors and various types of scaffolds should provide a stable environment to promote the growth of bone tissue, which is the standard that each bone substitute needs to meet.

At present, due to the need of long-term clinical treatment and complications, people are actively looking for biological bone scaffold delivery schemes with excellent drug loading and sustained release properties. In recent years, most reviews have summarized the biological scaffolds for bone tissue engineering from the perspective of materials, focusing on their manufacturing technology and mechanical stability. However, there are few reviews on the structure and function based on the combination of bone regeneration drugs and drug-loaded preparations. Considering the wide application of bone implantation and the need for local drug release therapy, in this article, the therapeutic matrices and applications of various types of drugs are described, focusing on various types of drug delivery systems, including microspheres, liposomes, and mesoporous silica nanoparticles. (Figure 2) The scheme of combining a drug-loaded system with a bone scaffold is also discussed, and its mechanical properties, drug loading and release properties, 3D structure, osteogenic effect and biocompatibility are evaluated. Finally, the drug carrier materials currently used in bone tissue engineering are presented, and their future development is predicted. By understanding the uses of drug carrier materials in bone tissue engineering, they can be used to mimic the structure and function of natural bone in the human body, thereby promoting bone tissue regeneration.

|

Figure 2 Application of different drug delivery systems in bone tissue engineering. |

Drugs Delivered in Bone Tissue Engineering Composite Scaffolds

In recent years, drugs, growth factors, natural pharmaceutical compounds and mesenchymal stem cells have been found to have osteogenic effects in vitro and in vivo, as shown in Table 1. Moreover, loading these osteogenic substances into bone scaffolds is widely considered to be a very effective strategy.

|

Table 1 Drug Delivery in Composite Scaffolds for Bone Tissue Engineering |

Growth Factor: BMPs

Growth factors widely exist in organisms, and they are active protein or polypeptide substances that regulate the growth and development of organisms. Among them, BMPs is widely used to promote bone formation. Bone morphogenetic proteins (BMPs) is a group of highly conserved functional proteins with similar structures and belong to the transforming growth factor β (TGF-β) family. BMP can stimulate DNA synthesis and cell replication, thereby promoting the directional differentiation of mesenchymal cells into osteoblasts. BMPs help maintain healthy bones by stimulating the mineralization, differentiation and survival of osteoblasts. In recent years, a large number of in vivo and in vitro research have shown that BMPs seem to play an important role in regulating osteoblast-osteoclast communication.64,65 Therefore, in an increasing number of studies, BMPs are added to bone scaffolds with the goal of obtaining better osteogenic effects. Unfortunately, BMP is a protein drug that degrades rapidly in vivo. Studies have shown that when the bone scaffold is immersed in saline containing BMP and filled into the bone defect site, it is quickly cleared and cannot achieve the desired bone formation and healing.66 If the dose is increased to maintain osteogenesis in the body, it may lead to serious side effects, such as hematoma, inflammatory response, and ectopic bone formation.67 Thus, it is important to create a delivery system that can facilitate the release of a sufficient drug dose over time.

In 2018, Chen’s team67 surface-immobilized rhBMP-2 in three ways, physical adsorption, covalent grafting, and heparin binding, to investigate the effect of the surface immobilization mode on rhBMP-2-induced osteogenesis in vitro and in vivo. The results showed that the osteogenic effect of the modes was in the order of physical adsorption mode < covalent grafting mode < heparin binding mode. Heparin enhanced the recognition of rhBMP-2 by BMP receptors (BMPRs) and weakened its binding to Noggin. Overall, this selective binding ability holds promise as a growth factor enhancer.

Small Molecule Drugs

To speed up the regeneration and repair of bone injury, people are often committed to the effective combination of biomaterials and drug molecules. Some small molecule drugs, such as neovastatin, dexamethasone, deferoxamine, adenosine, and aspirin, have been shown to have great benefits in inducing bone regeneration, although they do not all target bone tissue. Although aspirin, as a non-steroidal anti-inflammatory drug, has also been shown to inhibit osteoclast formation and improve bone formation.34 Adenosine is a purine nucleoside that is ubiquitous inside and outside the cell. It is often used as an antiarrhythmic drug, and it is also actively involved in bone homeostasis and bone regulation.32 Biomaterial scaffolds act as a local drug delivery system, encapsulating drugs in scaffolds to maintain activity or releasing drugs as needed to regulate the activity of cells in tissues, including cell coordination, proliferation and differentiation. For example, alendronate, a representative drug for the treatment of osteoporosis, can prevent the loss of bone tissue and effectively inhibit bone resorption caused by bone cement particles such as calcium phosphate. However, alendronate can bind to the calcium in calcium phosphate, thereby affecting its curing. To make up for this defect, alendronate can be loaded into microspheres or liposomes.28,68,69

Antibiotics

Chronic osteomyelitis and infectious bone defects are great challenges in orthopedic treatment. This is a serious complication that can cause the lesion to be difficult to heal, threaten limb loss, prolong the treatment cycle and the patient ‘s pain.44 About two-thirds of bone infections are caused by Staphylococcus aureus, which can adhere to the surface of bone tissue to form a biofilm and is extremely difficult to remove after infection.43 Early use of antibiotics such as vancomycin, gentamicin, levofloxacin, ciprofloxacin, and cefalexin for prevention has been shown to significantly reduce the incidence of related bone infections. It is worth noting that tetracycline can react with hydroxyapatite, the main component of bone tissue, and then be absorbed by bone to achieve bone targeting.46 At present, the use of systemic antibiotic therapy is more popular in clinical practice. However, both oral and injection must be repeatedly administered at high doses to maintain the effective concentration in the blood. This can lead to increased bacterial resistance to antibiotics. In addition, systemic distribution patterns make it difficult to cross areas of impaired vascularization and biofilm formation to reach infected tissues.47 In current clinical practice, antibiotic-loaded bone cement has been developed to eliminate bacteria and promote bone regeneration.17,45,70 In this study, people are also keen to design bone scaffold strategies with large load and continuous release of antibiotics. These scaffolds are designed to reduce the large dead space, eliminate regional bacterial reproduction and bacterial biofilm formation, and achieve effective prevention and treatment of infection.

Natural Pharmaceutical Compounds

Natural pharmaceutical compounds are natural organic compounds extracted from herbaceous plants in nature, and their novel chemical structures give them wonderful functions. Because natural pharmaceutical compounds have a wide range of sources and are easy to extract and prepare, they are often more cost-effective. In addition, the active ingredients of natural drugs are safer and can replace synthetic drugs to reduce long-term side effects. Natural pharmaceutical compounds have great potential in bone tissue regeneration. Pharmacological studies have shown that natural pharmaceutical compounds contribute to bone regeneration. For example, the mechanism of action of icariin is to activate the ER-α-Wnt/β-catenin signaling pathway, thereby inducing bone formation.36 A previous study has shown that curcumin can inhibit the phosphorylation and degradation of nuclear factor-κβ inhibitor (Iκβ), leading to the formation of inactive conjugate NF-κβ-Iκβ. This pathway plays a role in the differentiation of osteoblasts and the inhibition of osteosarcoma growth.40 Cannabidiol (CBD) is a bioactive molecule extracted from cannabis. Kamali et al have shown that CBD enhances the migration of MSC by activating P42/44 MAPK, and it has been confirmed that CBD can induce MSC to differentiate into osteoblast lineage in vitro and in vivo.39 However, most natural drugs exhibit poor bioavailability and are rapidly metabolized and cleared after entering the body.38,41 Sarkar et al proposed using hydrophobic polyphenolic liposomes of curcumin to enhance absorption into cells and tissues and improve targeted distribution of drugs.40 Moreover, Lai et al studied polymer scaffolds incorporated with icariin to improve the mechanical properties of scaffolds.37 In summary, understanding the chemical and pharmacological mechanisms of natural medicines and the interaction of biological materials can aid in the design of more practical bone repair scaffolds.

Stem Cells and microRNA

When the bone scaffold is implanted into the bone defect site, the lesion site produces an inflammatory response and recruits stem cells.71 The repair and functional reconstruction of bone injury ultimately depend on cells, and stem cells have been shown to play an important role in this process.71 Stem cells have the ability of self-renewal and multi-directional differentiation, and can differentiate into osteoblasts in bone tissue to promote bone tissue growth. Natural regeneration of bone tissue usually requires regenerative stem cells and scaffold-like extracellular matrix (ECM). The introduction of exogenous stem cells can regulate the microenvironment because they secrete a variety of factors, such as collagen, cytokines, and growth factors, thereby promoting osteoblast differentiation and mineralization.58 Mesenchymal stem cells (MSCs) have been widely used in bone regeneration engineering due to their excellent proliferation and differentiation ability and low immune rejection. Other stem cells such as induced pluripotent stem cells (iPSCs) and embryonic stem cells (ESCs) have also been shown to effectively promote bone regeneration.72 However, the migration, colonization, proliferation and differentiation of stem cells need to obtain information from the outside world. Its differentiation direction depends on the microenvironment. By receiving different signals, stem cells achieve satisfactory proliferation and differentiation to repair or form tissues. Therefore, it is necessary to design biomaterial scaffolds that mimic the ECM. Bone scaffolds fabricated by electrospinning and 3D printing are widely used to construct a suitable microenvironment for stem cell osteogenesis. They can provide irregular and rough surface, which is conducive to cell adhesion and proliferation, and is sought after.54,73

MicroRNAs (miRNA) are a kind of noncoding single-stranded RNA molecules with a length of about 22 nucleotides encoded by endogenous genes, which are involved in the regulation of post-transcriptional gene expression in bone tissues. In recent years, the use of microRNAs to induce osteogenesis and promote neovascularization of osteoblasts is expected to become an alternative approach for bone tissue engineering. An increasing number of miRNAs have been identified as regulators of factors specific to bone development, osteoblast differentiation and osteoporosis pathology.63 Some compounds, such as miRNA-26a, -135, and -148b, have been shown to induce new bone formation, as indicated by increased total alkaline phosphatase activity and increased expression of early specific biomarkers.74 They mainly regulate the osteogenic differentiation of MSCs from osteoblast precursor cells to mature osteoblasts through bone morphogenetic protein signaling pathway and wnt/β-catenin signaling pathway.75 In general, viruses, stem cells, or liposomes are commonly used delivery vectors for miRNAs in bone scaffolds. In the study of Liu et al, bone regeneration and newly formed bone volume were increased in the miRNA-26a-transfected BMSC group compared with the blank group, and the mRNA and protein expression levels of runt-related transcription factor 2 and osteocalcin were further increased.62

Drug-Loaded Bone Scaffolds

Various bone graft composite biomaterials have been clinically successful. The main biomaterials include polymers (natural polymers and synthetic polymers), inorganic calcium-containing compounds and degradable metals. Drugs, peptides, and stem cells with osteogenic potential are added to the implant to enhance osseointegration. The following focuses on commonly used methods of drug delivery and the interaction between medicinal chemistry and biomaterials. And using drug-loaded scaffolds is an innovative strategy proposed by researchers to repair bone defects.

Inorganic Drug-Loaded Bone Scaffolds

Bone is mainly composed of a composite of the inorganic minerals calcium phosphate and organic collagen, and the interconnected macroporous structure enables guest molecules and cells to pass through the inorganic network through pores and channels.10,76 In general, artificial bone scaffolds need to possess various properties similar to bone tissue to maintain bone strength in bone defect areas and promote bone regeneration; such properties include sufficient mechanical strength, excellent biocompatibility and degradability, and a porous network structure for cell growth.77–80 Hydroxyapatite (HAP),81 tricalcium phosphate (TCP),82,83 biphasic calcium phosphate (BCP),84 bioglass (BG),85 carbon nanotubes (CNTs)86,87 and other inorganic synthetic materials, because of their good biocompatibility, help the proliferation and adhesion of osteocytes and have become popular bone scaffold materials.88 Such inorganic bone implant materials, known as bioabsorbable materials, degrade over time and are replaced by bone tissue.89,90 In fact, the inorganic material HAP may still be integrated into the regenerated bone tissue after implantation, while TCP, etc., are completely resorbed.91,92

In order to construct a carrier-type slow-release bone scaffold, the underlying structure must be able to physically or chemically incorporate the drug, where its activity can be maintained. Then, as the scaffold gradually decomposes, the drug can be released over time.93 Calcium phosphates, as the most commonly used inorganic bone materials in bone tissue engineering, are generally divided into cement,94 nanoparticles,51,52 scaffolds25,76 and coatings95 for loading. During cement synthesis, drugs can be loaded from solution or added in the solid phase.94 In contrast, it is also possible to perform imprinting on scaffolds or nanoparticles by immersion, stirring and mixing in a solution containing the therapeutic factor.25,76,96 Although the treatments described in the literature are always effective, the loading of the drug cannot be determined, with pore size, porosity, and surface chemistry being the main influencing factors.90,97 Electrodeposition,95 biomimetic coating or mineralization,98 and plasma spraying99 are used to coat metal implants with a layer of drug-containing calcium phosphates to improve bioactivity and bone conductivity. Moreover, metal implants can cause infection during orthopedic surgery, posing a serious threat to long-term stability in the body.100,101 This challenge can be addressed by local delivery of antibiotic drugs from coated implants. The following mainly describes the design of inorganic bone tissue materials and the release kinetics of loaded antibiotics.

Since, in most cases, drugs or growth factors cannot specifically bind to the cement matrix, release is usually rapid, reaching >95% within a few days.96 However, some drugs may require a more gradual and sustained release strategy. For example, VEGF has a potential tumorigenic risk, so its uncontrolled release must be strictly avoided.102 For the treatment of infection, an initial burst of antibacterial and anti-inflammatory drugs is released at the implant site to effectively inhibit microbes, ideally in controlled amounts to avoid toxicity or bacterial resistance, and sustained release then continues at low concentrations.97,103,104 It is worth noting that in most calcium phosphate materials, there are two release concentration gradients, namely, the initial fast release period and the subsequent slow release period.76,105 Under actual experimental conditions, the drug release kinetics conformed to the Korsmeyer-Peppas equation and the port mode.94,96 Conversely, other factors may also affect drug release kinetics, such as diffusion, changes in cement matrix composition, different drug solubilities, and drug/matrix interactions.97,106

Results of the study by Lucas-Aparicio et al showed that the release rate of Si-β-TCP was faster than the initial release rate of silicon-free ceramic (β-TCP) (see Figure 3A).103 This result is consistent with a specific delivery mechanism that assumes a homogeneous distribution of pores, a combination of drug dissolution and diffusion processes in the matrix. The structural change of the Si-β-TCP matrix is caused by the influence of factors such as the microporosity, porosity, average pore size, and surface area of the TCP matrix.107,108 Although diffusion-controlled release is the main release mechanism of different types of cement, it can be seen from the graph that CPC and 40% Si-β-TCP showed an initial release. Additionally, the release rate changed with the drug concentration and followed first-order kinetics. However, the release rate of 80% Si-TCP showed linear behavior and was independent of the amount of dissolution. The Jatsue group also found that the release curve of bone cement prepared with β-TCP and 40% Mg-TCP followed the Fickian diffusion law (n<0.45), while the drug release rates of 26.67% Mg-TCP and 66.67% Mg-TCP were higher. Zero-order release and anomalous transfer mechanisms can account for 0.45<n<0.89 (Figure 3B).94 In summary, the pore size, pore distribution and surface area of the matrix are the main factors determining the release curve, and these properties are related to the pore connectivity, geometric shape and matrix stability. Porosity has a great influence on drug metabolism.

|

Figure 3 (A) Pharmacokinetic analysis of vancomycin on β-TCP and Si-β-TCP. The halo images were suppressed by adsorbing 80% Si-β-TCP and 80% Si-CPC loaded with vancomycin. Pharmacokinetic analysis of vancomycin from CPC, 40% Si-CPC and 80% Si-CPC. (B) Release curves of cement prepared with three different concentrations of magnesium compared with unsubstituted cement. (C) The release spectra of four kinds of vancomycin mixed with HAP1 and HAP2 in different weight ratios and the time to complete the release of vancomycin in these four kinds of cement. (D) The release spectra of four kinds of ciprofloxacin mixed with HAP1 and HAP2 in different weight ratios and the time to complete the release of ciprofloxacin in these four kinds of cement. Notes: (A) Reprinted from Mater Sci Eng C-Mater Biol Appl, 106(8), Lucas-Aparicio J, Manchon A, Rueda C, et al. Silicon-calcium phosphate ceramics and silicon-calcium phosphate cements: Substrates to customize the release of antibiotics according to the idiosyncrasies of the patient. 110173. Copyright 2020, with permission from Elsevier.103 (B) Reprinted from Mater Sci Eng C Mater Biol Appl, 61, Cabrejos-Azama J, Alkhraisat MH, Rueda C, et al. Magnesium substitution in brushite cements: Efficacy of a new biomaterial loaded with vancomycin for the treatment of Staphylococcus aureus infections. 72–78. Copyright 2016, with permission from Elsevier.94 (C) and (D) Reprinted from Ghosh S, Wu V, Pernal S, Uskokovic V. Self-Setting Calcium Phosphate Cements with Tunable Antibiotic Release Rates for Advanced Antimicrobial Applications. ACS Appl Mater Interfaces. 2016;8(12):7691–7708. Copyright 2016, with permission from American Chemical Society.47 |

The research of Shreya team on calcium phosphate bone cement is also worth thinking about.47 HAP1 and HAP2, which are identical in chemistry, morphology and crystallography, are prepared, and the release kinetics of antibiotics is regulated by different proportions of them. As shown in the Figure 3D, the higher the content of HAP1 in the cement carrying ciprofloxacin, the slower the release rate; on the contrary, the greater the content of HAP2 in cement, the faster the release rate. The principle may be that HAP2 bypasses dicalcium phosphate as an intermediate product and directly transforms from amorphous to crystalline HAP. This process prolongs the time for HAP2 to remain amorphous. The entropy similarity between amorphous calcium phosphate and liquid phase makes it easier for drug molecules to transfer from the surface, which is conducive to drug loading and release. In addition, surface hydration weakens the binding of proteins and allows rapid drug release from HAP2.109,110 It is worth noting that the synergistic effect between the drug and the carrier is the ultimate factor determining the release characteristics. The release spectrum of vancomycin-loaded HAP was opposite to that of ciprofloxacin (Figure 3C and D).

Mesoporous Silica Drug-Loaded Bone Scaffolds

The proliferation, migration, adhesion and differentiation of bone cells contribute to bone regeneration.111,112 Ideally, bone scaffolds not only provide structural support for implanted cells but also provide osteogenic agents to regulate cellular responses and repair tissue repair.113–116 Therefore, the selection of scaffold materials and their surface properties are the key to bone tissue engineering. Inspired by some superior properties of mesoporous silica nanoparticles (MSNs), it was found that the integration of bone scaffolds and monodisperse silica may be a powerful strategy for the construction of bone regeneration control transfer systems.117

In recent years, MSNs have become an ideal drug carrier. Due to their low cytotoxicity,118,119 high porosity,120 high mechanical strength,121,122 high cost performance123 and good biocompatibility,124 MSNs have shown beneficial properties for bone tissue engineering. First, an appropriate amount of soluble orthosilicic acid can increase the expression of type I collagen in human osteoblasts, thereby accelerating the differentiation of osteoblasts.125,126 In particular, early studies have shown that silicon is one of the key elements in bone and cartilage formation and plays a crucial role in bone and cartilage formation.127,128 In addition, silicon nanomaterials have low toxicity and good biocompatibility; their large active surface area and large pore volume facilitate their use as carriers for drugs, growth factors, and essential minerals.17,112,129 Furthermore, mesoporous silica not only has good stability but is also easy to functionalize. Its surface chemistry can be changed to modify its drug release patterns, its specific targeting capabilities, and its role in stem cell or scaffold tissue engineering.126,130,131

Although most drugs are loaded in the pores of MSNs, drug release behavior is mainly controlled by diffusion.130,132 When macromolecular drugs containing antibiotic MSN were applied to composite stents, the drug loading and encapsulation efficiency were low, and the drugs are released rapidly after application.133–135 Moreover, the surface of MSNs lacks organic functional groups, and the infiltration of inorganic microcarriers on the surface of scaffolds is still difficult.116 To solve these problems, the best strategy is to modify MSNs with functional groups.

Dexamethasone (Dexa) is a synthetic glucocorticoid. As an excellent bone inducer, it can promote osteoblast differentiation and enhance alkaline phosphatase activity and bone mineralization.116,136 However, its induction of osteoblast differentiation has a typical dependence on time and dose.29 Daryasari et al29 loaded Dexa into MSNs (MSN-Dexa) and then coated a layer of CS (MSN-Dexa@CS) on the surface of the MSNs. Finally, MSN-Dexa@CS/PLLA composites were formed by electrospinning PLLA solution. As shown in Figure 4A, in this system, CS physically covered the MSN outlet to form a “gate-like” container to achieve pH-sensitive release of intracellularly loaded Dexa. After being internalized into the cells, the loaded Dexa was released into the cytoplasm with the decrease in pH and the change in CS dispersion. Thus, Dexa plays a role in osteogenic differentiation.

|

Figure 4 (A) A schematic representation of a PLLA scaffold combined with MSN-Dexa@CS. (B) The fabrication process diagram of the Dexa@MSNs-NH2/PLLA/PCL composite scaffold. (C) A schematic of the effect of Dexa@MSNs-pep on osteogenic differentiation. (D) Difference of uptake of MSNs-pep and single nano-silicon in cells. TEM images show the absorption of MSN (a1 and a2) and MSNs-pep (b1 and b2) in BMSCs, and the comparison between them in measuring the silicon quality of BMSCs by ICP-OES (c). Compared with MSNs, the uptake of MSNs-pep nanoparticles increased significantly (**p<0.01). Notes: (A) Reprinted from Daryasari MP, Telgerd MD, Karami MH, et al. Poly-l-lactic acid scaffold incorporated chitosan-coated mesoporous silica nanoparticles as pH-sensitive composite for enhanced osteogenic differentiation of human adipose tissue stem cells by dexamethasone delivery. Artif Cell Nanomed Biotechnol. 2019;47(1):4020–4029. This is an open-access article distributed under the terms of the Creative Commons Attribution License. (http://creativecommons.org/licenses/by/4.0/).29 (B) Reprinted from Qiu KX, Chen B, Nie W, et al. Electrophoretic Deposition of Dexamethasone-Loaded Mesoporous Silica Nanoparticles onto Poly(L-Lactic Acid)/Poly(epsilon-Caprolactone) Composite Scaffold for Bone Tissue Engineering. ACS Appl Mater Interfaces. 2016;8(6):4137–4148. Copyright 2016, with permission from American Chemical Society.116 (C) and (D) Reprinted from Zhou XJ, Feng W, Qiu KX, et al. BMP-2 Derived Peptide and Dexamethasone Incorporated Mesoporous Silica Nanoparticles for Enhanced Osteogenic Differentiation of Bone Mesenchymal Stem Cells. ACS Appl Mater Interfaces. 2015;7(29):15777–15789. Copyright 2015, with permission from American Chemical Society.137 |

Similar to the above example, Qiu’s team116 prepared aminated mesoporous silica particles (MSN-NH2) and loaded Dexa into it. Poly(l-lactic acid)/poly(ε-caprolactone) (PLLA/PCL) nanofiber scaffolds were prepared by thermally triggered segment separation and used as templates to deposit drug-loaded MSN-NH2 by electrophoresis (Figure 4B). Studies have shown that the surface of MSNs can be functionalized with appropriate organic molecules to better control the release of therapeutic factors. These molecules can also be incorporated into both MSN mesoporous channels and organic coatings.

Zhou et al137 concluded that BMP-2 and Dexa combined with MSNs can synergistically enhance the osteogenic differentiation of BMSCs, a technique which has potential application value in bone tissue engineering. They synthesized BMP-2 peptide-functionalized MSNs (MSNs-pep) by covalently grafting BMP-2 peptide onto the surface of nanoparticles through an aminosilane linker and loaded Dexa into the monodisperse two-nanotube channel to construct a nano-osteogenic delivery system (Dexa@MSNs-pep). As shown in Figure 4C and D, peptide grafting not only endows the nanoparticles with better dispersion performance and biocompatibility, but also improves their high affinity for BMP receptors. Electrostatic adsorption of non-uniform surface charges can also enhance cell uptake. In addition, the BMP-2 protein interacts with the BMP receptor on the cell surface, thereby generating a polypeptide/BMP receptor complex and activating the Smad signal transduction pathway. When absorbed by cells, Dexa enters the cytoplasm and binds to receptors.

Polymer Drug-Loaded Bone Scaffold

Generally, artificial bone scaffolds need to have various properties that are comparable to those of bone tissue to maintain bone strength in bone defect areas and promote bone regeneration, such as sufficient mechanical strength, excellent biocompatibility and degradability, and a porous network structure for cell growth.77–80 Inorganic synthetic materials such as calcium phosphate have become widely used bone scaffold materials because of their good biocompatibility, which promotes the growth and attachment of bone cells. However, they are too brittle to maintain bone strength and usually require appropriate additives to be improved.26,138 Some natural polymers, such as collagen, gelatin, alginate, chitosan, and hyaluronic acid, and synthetic polymers, such as polylactic acid-glycolic acid copolymer (PLGA), polyethylene glycol (PEG), polycaprolactone (PCL), polyhydroxyalkanoate (PHA) and polylactic acid (PLA), are broadly used as additives in bone tissue engineering.139,140

For the construction of a drug- or growth factor-loaded and sustained-release bone scaffold using a polymer as a carrier, the simplest way to load a drug in a ceramic scaffold is dip-coating.141 The method utilizes the porous structure of the ceramic scaffold142 by immersing it in a coating solution containing a specific amount of drug, and the process is repeated more than three times to achieve the desired drug layer thickness on the ceramic scaffold.44,143 It is worth mentioning that in this method, the drug is adsorbed on the ceramic surface by a weak binding force, which cannot guarantee the long-term release of the drug. Curcumin144 has anti-osteoclast activity and osteoblast-promoting activity, but its solubility and high metabolic rate often hinder the expected efficiency. Bose et al145 added PLGA-PEG and PCL-PEG polymers to a HAP matrix, and the results showed that the transferred curcumin expressed good bone conductivity (Figure 5A and B). In drug delivery applications, the most common method is to combine polymers containing drugs and then apply polymer coatings on the surface of bioceramics to control drug release behavior.44,146 Liang et al studied the application of polycarbonate with carboxylic acid structure in bone cement. Due to the covalent interaction with the antibiotic-gentamicin in commercial bone cement, the biocement has high processing capacity and adjustable release kinetics (Figure 5C).70 Polymers can be used to transport drugs with poor solubility.147,148 In addition, the addition of polymer can enhance the mechanical properties of bioceramic scaffolds and increase mechanical strength (Figure 5D).145

|

Figure 5 (A) The release profile of curcumin from HA in pH7.4 and pH5.0 showed that the release of curcumin in the first 24 hours increased by 39% and 64%, respectively, compared with that without polymer. (B) Optical microscopy images of extracellular matrix formation, angiogenesis and bone formation after 6 weeks of rat femur surgery. (C) In vitro release curve of gentamicin from each doped polymer (1%) cement. Compared with the control group (Gentamicin), the release of gentamicin mixed with cement increased significantly (***p<0.0001). (D) Elastic modulus, compressive yield and compressive strength of various polymer-doped cements with polymer content of 1% and 5%. Comparing the mechanical strength of each group, some of them have improved their mechanical properties in different degrees (*p<0.05, ***p<0.0001). Notes: (A) and (B) Reprinted from Mater Today Chem, 8, Bose S, Sarkar N, Banerjee D. Effects of PCL, PEG and PLGA polymers on curcumin release from calcium phosphate matrix for in vitro and in vivo bone regeneration. 110–120. Copyright 2018, with permission from Elsevier.145 (C) and (D) Reprinted from J Control Release, 329, Liang ZC, Yang C, Ding X, Hedrick JL, Wang W, Yang YY. Carboxylic acid-functionalized polycarbonates as bone cement additives for enhanced and sustained release of antibiotics. 871–881. Copyright 2021, with permission from Elsevier.70 |

In the past two decades, synthetic polymer-based drug-loaded scaffolds have been more popular than natural polymer-based drug-loaded scaffolds in bone tissue engineering due to their excellent porosity, degradation rate and mechanical properties.149 The lack of potential endotoxin substances and their inferior mechanical properties limits the use of natural polymers.150 In addition, to obtain better drug loading, mechanical properties, and biocompatibility, a series of nanofillers, such as nanohydroxyapatite (nHAP), mesoporous silica, and various nanoparticles, are incorporated into natural and/or synthetic polymer matrices and are widely used in bone tissue regeneration research platforms.

Microsphere Drug-Loaded Bone Scaffold

Prolonged drug release can also be achieved by creating absorbable microcarriers to release drugs within a designed time, and microsphere bone scaffolds are the more common type of drug-loaded bone scaffolds. Microspheres (1–1000 μm) are particle dispersion systems formed by dispersing drugs/bioactive molecules or being adsorbed in polymers or polymer matrices. Microspheres are ideal carrier materials due to their large surface and volume, which allow them to carry and release drugs.151,152 In general, any surgical procedure has a potential risk of inflammation and bone infection, which traditionally needs to be prevented by prolonged (2–6 weeks) antibiotic treatment,153,154 and the recovery of bone tissue is a long process. The sustained release of microsphere-loaded growth factors can promote osteogenesis.155–157 Chen et al prepared gentamicin sulfate/alendronate-double-loaded gelatin-modified PMMA bone cement (GAPBC) and found that the gel has multiple functions, fast and sustained antibiotic release, and can be effective in the treatment of osteoporosis.28

Moreover, the advantages of loading drugs, bioactive molecules, etc., on the microspheres also lie in their adsorption and encapsulation effects: (1) Some drugs have toxic effects on normal cells or tissues of the human body. The drugs encapsulated in the microspheres can maximize their efficacy and avoid adverse effects on other parts of the body.158 (2) Microspheres can easily adsorb aggregated drugs to achieve an effective therapeutic concentration.159,160 (3) When the bone cement is mixed, the drug and bioactive molecules are encapsulated in the particles to prevent the loss of efficacy or growth factor activity due to environmental changes (such as pH value and charge conditions).161,162 (4) Because of the chemical structure of some drugs, they easily react with bone matrix materials and affect the recovery process. For example, the high water solubility of alendronate prevents its incorporation into bone cement powder because it chelates calcium ions. Alendronate can dissolve quickly, which increases the content of calcium ions and affects bone adhesion.28 Tetracycline chelates Ca2+ ions, thereby interfering with the deposition of minerals, preventing mineralization, delaying the curing reaction, and prolonging the curing time.160,163

As mentioned in the previous section, many studies in bone tissue engineering directly load and release drugs or growth factors through ceramic scaffolds such as HAP, tricalcium phosphate, and bioglass.25,52,164 In general, the unmodified ceramic scaffold has an initial rapid release of drug, accompanied by relatively sustained release.143,165 Unstable release may be due to partial adsorption of the drug on the surface of the scaffold rather than being incorporated into the pores of the scaffold.166 Adding microspheres to ceramic scaffolds is an ideal solution to control drug release. Yu et al167 loaded naringin into gelatin microspheres and encapsulated these microspheres, which have good release performance, in silk cellulose/nHAP scaffolds. In addition, the large specific surface area of the microspheres can increase the surface roughness, thereby improving cell adhesion and proliferation, and is also conducive to mineral nucleation.168–170

Moreover, some studies have shown that the performance of microspheres (drug loading efficiency and encapsulation efficiency) is much higher than that of inorganic nanoparticles.152,171 In addition, microspheres can be designed as a stimuli-responsive drug-release system. Different media conditions lead to different degradability and different release behavior. The Bi team171 successfully prepared HAP/sodium alginate/chitosan (HAP/SA/CS) composite microspheres with good pH-sensitive drug release ability by utilizing the degradability of HAP and chitosan in acidic media (Figure 6A and B). It is worth noting that appropriate drug-loaded microspheres added to the scaffold can improve the porosity and mechanical properties of the composite scaffold and maintain structural stability. However, excessive addition may lead to a decrease in the compressive modulus.172,173 Therefore, the proportion of the introduced microspheres should be within a certain range, and maintaining an appropriate balance between overall porosity and mechanical properties is a key factor affecting the performance of microsphere scaffolds. Interestingly, microspheres were directly molded into scaffolds in one study. He’s team173 incorporated polylactic acid (PLLA), oleic acid-modified HAP (OA-HAP) and vancomycin hydrochloride into polytrimethyl carbonate microspheres. By adding the combination of PLLA and OA-HAP with polymer chains, the mechanical properties of the microsphere scaffolds were effectively improved, and the biodegradation of microspheres was slowed, showing acceptable biocompatibility for applications in bone tissue engineering (Figure 6C).

|

Figure 6 (A) Preparation process of hydroxyapatite/sodium alginate/chitosan (HA/SA/CS) composite microspheres. (B) In vitro drug release curves of HA/SA/CS composite microspheres loaded with DOX at different pH values. (C) Scaffold characteristics: SEM images (a1–a4); compression modulus and compressive strength (b); porosity and pore size (c); water absorption of microspheres (d) and hydrolysis (e) and enzymatic hydrolysis (f) in the degradation cycle (Compared with the control value, *p<0.05, **p<0.01, ***p<0.0001). Notes: (A) and (B) Reprinted from Mater Sci Eng C-Mater Biol Appl, 100, Bi YG, Lin ZT, Deng ST. Fabrication and characterization of hydroxyapatite/sodium alginate/chitosan composite microspheres for drug delivery and bone tissue engineering. 576–583. Copyright 2019, with permission from Elsevier.171 (C) Reprinted from Carbohydr Polym, 253 (9), He J, Hu XL, Cao JF, et al. Chitosan-coated hydroxyapatite and drug-loaded polytrimethylene carbonate/polylactic acid scaffold for enhancing bone regeneration. 117198. Copyright 2021, with permission from Elsevier.173. |

Liposome Drug-Loaded Bone Scaffold

Liposomes are closed vesicles with a two-layer structure that are formed by dispersing amphiphilic molecules such as phospholipids and cholesterol into water.174–176 Due to the hydrophobicity of the tail and the hydrophilicity of the head, the tails are easily aggregated to form an inner layer to avoid contact with water, and the heads form an outer layer where they are exposed to water.177,178 This special self-assembled vesicle structure enables these carriers to load hydrophilic substances in the internal aqueous phase and hydrophobic substances in the bilayer.31,174,179 Liposomes were discovered by Benham in 1964; since then, an increasing number of scholars have studied them. Liposome nanotechnology has been developed significantly.180 The advantages of good biocompatibility, satisfactory drug loading and stability, low cytotoxicity and immunogenicity, strong passive targeting ability and easy surface modification make liposomes excellent carriers.34,35,181,182 When liposomes are fixed/bound to biomaterial scaffolds, they have special advantages in controlling the transmission of growth factors, genes, proteins, etc. Their structures and surface properties can be optimized for specific needs.174,183,184

In a composite scaffold delivery system, liposomes can also play the same role as microspheres. In general, carrier devices for the delivery of proteins and other active biomolecules should be able to maintain the stability of the delivered proteins.185 An ideal drug delivery system can prevent the denaturation of drug molecules and achieve efficient delivery.186,187 Core-shell nanofibers can prevent denaturation and facilitate the injection of sensitive molecules into liposomes.188 In addition, a mixture of cationic liposomes and neutral lipids can be used to promote nucleic acid transmission.189 Viruses and nonviruses (ie, liposomes, cationic lipids, polymers, proteins) can act as vectors of transfected cells.24,190 The use of viral vectors increases gene expression and transduction efficiency, but also brings immunological risks and has limited applicability and limitations in gene insertion.191 Fortunately, cationic lipids have become the choice for use in gene transfer, and some lipids with cationic head groups have been synthesized and evaluated for cell transfection.192 Unfortunately, their transfection efficiency is relatively low.193,194

Drugs are coupled with biomaterial scaffolds to provide ideal therapeutic performance and mechanical support. However, the use of this technique alone may lead to problems, such as the abrupt release of drugs and potent side effects in unintended locations.195

Lee and her collaborators created apatite-PLGA 3D scaffolds that mimic trabecular bone and were combined with bone-induced oxidation liposomes.184 Sequential functionalization of polydopamine (PD) and bone-induced oxysterol (Oxy) liposomes altered the chemical composition of the scaffold surface, which indicated that Oxy liposomes were successfully added to the scaffold. By coordinating with hydroxyl-rich catechol groups and cations like calcium, the PD substrate was easily immobilized on the surface of apatite-PLGA to create PD-coated apatite-PLGA scaffolds under weakly alkaline conditions (Figure 7). Additionally, a Schiff base reaction and Michael addition reaction between catechol on PD-PLGA and amine on Oxy liposomes anchored Oxy liposomes on the surface of PD scaffolds.196 Interestingly, Oxy liposomes were immobilized to protect the scaffold from the potential toxicity of many positive charges and ensure its biocompatibility. Further PD coating significantly reduced the toxicity.

|

Figure 7 Synthesis of smooth agonist (SAG)-loaded oxidized liposome-coated PLGA scaffolds for bone transplantation to treat skull defects in mice. Notes: Reprinted from Lee CS, Hsu GCY, Sono T, Lee M, James AW. Development of a Biomaterial Scaffold Integrated with Osteoinductive Oxysterol Liposomes to Enhance Hedgehog Signaling and Bone Repair. Mol Pharm. 2021;18(4):1677–1689. Copyright 2021, with permission from American Chemical Society.184 |

The traditional drug delivery system is passive release based on polymer materials. The rate of drug release depends on the rate of diffusion of the carrier and/or the rate of degradation of the carrier.197 Lee et al used sterol oxide to construct nonphospholipid liposomes, which are a potential self-assembly drug transport carrier for applications in bone tissue engineering.184,198,199 Nonphospholipid vesicles have large sterol levels compared to phospholipid liposomes, which creates a durable double molecular layer with the lowest permeability, allowing for the controlled and sustained distribution of drugs (Figure 7).200

Hydrogel Drug-Loaded Scaffold

Hydrogel is a kind of extremely hydrophilic three-dimensional network structure gel. It swells rapidly in water and can maintain a large volume of water without dissolution. Because of its good biocompatibility, high water content, mechanical elasticity and good permeability to nutrients, it constructs a microenvironment suitable for cell growth and is widely used in drug delivery of bone tissue engineering, especially stem cell delivery.201,202 They can not only produce porous structures to capture cells or proteins, but also form chemical bonds with drug genes, leading to drug release.203,204 Hou et al14 prepared degradable polyvinyl alcohol (PVA) microgels by high-throughput microfluidic technology, so that hMSCs loaded in them maintained high activity. In addition, regulating the crosslinking density of PVA microgels can affect cell proliferation and migration, and co-loaded BMP-2 promotes osteogenic differentiation of hMSCs (Figure 8A and B). It is worth noting that hydrogels can be designed to deliver encapsulated therapeutic factors, proteins and cells to specific sites corresponding to physiological stimuli such as pH, enzyme and temperature.205,206 Kim’s team207 synthesized a bioconjugate by postmodification by combining temperature-responsive PCLA and O-phosphorylated functional groups. Free flow at low temperature (37°C) can be transformed into a stable viscoelastic gel. BMP-2-loaded bioconjugates formed stable gels in vivo and showed sustained release (Figure 8C and D).

|

Figure 8 (A) During the incubation period of 4 weeks, the proliferation rate of hMSCs in polymer hydrogel and the alizarin red staining of its cells were observed. (B) The ALP activity and relative Runx2 and OPN gene expression of hMSCs cultured in BMP-2-treated or untreated hydrogels (mean ± SD, n = 3, *p<0.05, **p<0.01). (C) Extracellular simulation of in situ formation of injectable bio-coupled hydrogel loaded with BMP-2 and its sustained release to repair bone defects. (D) The concentration of BMP-2 in serum of SD rats at each time point. Notes: (A) and (B) Reprinted from Acta Biomater, 77, Hou Y, Xie W, Achazi K, et al. Injectable degradable PVA microgels prepared by microfluidic technology for controlled osteogenic differentiation of mesenchymal stem cells. 28–37. Copyright 2018, with permission from Elsevier.14 (C) and (D) Reprinted from Carbohydr Polym, 233(11), Kim SH, Thambi T, Phan VHG, Lee DS. Modularly engineered alginate bioconjugate hydrogel as biocompatible injectable scaffold for in situ biomineralization. 115832. Copyright 2020, with permission from Elsevier.207 |

Auxiliary Drug-Loaded Bone Scaffold Technology: 3D Printing Technology and Electrospinning Technology

3D printing technology is expected to promote the development of customized and integrated engineered bone tissue. 3D printing technology is a combination of software design and materials to accurately produce personalized bone tissue engineering scaffolds. Due to the imaging observation and analysis of bone defects and lesions, the 3D printed bone scaffold is perfectly bridged with the desired site. The purpose of biomaterials is to promote the growth of bone tissue at the defect site and eventually degrade in situ and be replaced by new bone tissue. Through 3D printing technology, a variety of polymer materials, such as artificial materials, natural materials, or a mixture of the two, can be used to prepare diversified bone tissue scaffolds with nanostructures.208 Due to its ability to create structures with high specific surface area, high porosity, bionic ECM structure and good biocompatibility, 3D printing technology has broad application prospects.209–212 In addition, functional nanofibers can carry many biologically active proteins, peptides, and small molecule drugs, thereby enhancing cell adhesion, proliferation, and differentiation.213–215 Therefore, 3D-printed scaffolds have become important in the biomedical field due to their ECM-like structure and bioactive material loading.216,217

The disadvantage is that neither drugs, peptides, proteins, targeted substances and cell cultures cannot be added by 3D printing because elevated temperature will lose the biological activity of these therapeutic molecules.218,219 In addition, porous scaffolds with large specific surface areas based on 3D printing are generally loaded by impregnation.11 However, in this physical mode of adsorption, the drug release rate is faster mainly due to weak force interactions such as electrostatic adsorption, hydrogen bonding, and hydrophobic interactions.220 Dang et al215 used PCL and fused deposition modeling (FDM) to prepare a dual microporous-macroporous scaffold and chose doxorubicin (DOX), paclitaxel (PTX) and cefazolin (CEF) as model drugs with properties and solubilities conducive to scaffold immersion loading. It was found that the microscale porosity significantly reduced the burst release, permitting the microporous scaffold to release DOX, PTX and CEF for up to 200, 500 and 150 hours, respectively. In addition to changing the microporous structure, the use of surface modification or coating growth factors are also commonly used strategies.67 Lai et al221 prepared porous PLGA/β-TCP/Mg (PTM) scaffolds by low-temperature rapid prototyping. The results showed that the early release of Mg2+ showed burst release through diffusion, which was regulated by Mg and TCP content. After 4 weeks, Mg2+ was released slowly and continuously with the degradation of PLGA (Figure 9A). During these two release processes, the concentration of Mg2+ was within the normal reference range, and in vivo omics analysis also showed the osteogenic and angiogenic ability of PTM scaffolds (Figure 9B).

|

Figure 9 (A) Release of surface particles and accumulated magnesium ions and calcium ions during degradation by scaffold analysis. SEM images showed the morphology and particle distribution of the scaffold (a). Proportion ratio of each element in PTM stent (b) and cumulative release of Mg2+ (c) and Ca2+ (d). (B) Histological analysis of bone formation after stent implantation. Histological analysis of decalcified sections, in which the blue arrow shows new bone (a). Fluorescence microscope image of decalcified section, in which white arrow indicates bone formation (b). Quantitative analysis of new bone formation (c1–c4). n=3 in each group; compared with the control group, ***p<0.0001; compared with PT group, ##p<0.01, ###p<0.0001. Notes: (A) and (B) Reprinted from Biomaterials, 197, Lai Y, Li Y, Cao H, et al. Osteogenic magnesium incorporated into PLGA/TCP porous scaffold by 3D printing for repairing challenging bone defect. 207–219. Copyright 2019, with permission from Elsevier.221 |

Similarly, fibrous bone scaffolds prepared by electrospinning technology are also a research hotspot in bone tissue engineering. Electrospinning technology is to eject the molten polymer through a syringe, form a fiber through the collector, and then stack the fibers in a specific program or irregularly to form a porous nano-scaffold. Because of the irregular arrangement of the scaffold, its total surface area increases, so that cells can better adhere and proliferate on the rough surface. In general electrospinning and 3D printing are quite different techniques, however, in some cases even electrospun scaffolds are referred to as 3D scaffolds. Different electrospinning techniques form hollow, core-shell, beaded nanofibers with different structures, making them high-load drug delivery materials. Because of the degradation performance and high porosity of drug-loaded electrospinning fibers, the 3D structure effectively controls drug release and has high affinity for local tissue.222,223 To achieve long-term release of drugs from electrospun materials, coaxial electrospinning is generally used to prepare drug-loaded fiber scaffolds. As a classic sustained-release structure, coaxial electrospinning can produce core-shell fibers, which can merge and release bioactive agents such as drugs, growth factors, and cells in a controlled manner.223–225 Carvalho et al226 used electrospinning to fabricate cell-derived ECM mesh scaffolds with high porosity and interconnectivity, simulating the structure and composition of natural bone ECM (Figure 10A and B). In addition, adenosine is incorporated into the internal layer of coaxial nanofibers to achieve controlled release of adenosine while avoiding excessive adenosine accumulation that may lead to skeletal system disorders.32 In an in vitro study, the core-shell nanofiber structure protected platelet-rich fibrin in the core layer from solvent and microenvironment changes. Compared with uniaxial nanofibers, nanofibers have lower platelet-rich fibrin release.21

|

Figure 10 (A) Schematic of the fabrication of cell-derived ECM microfibrous scaffolds. (B) SEM observations at lower magnification (a) and at a higher magnification (b), and fiber diameter distributions (c) of ECM PCL electrospun scaffolds from different cell sources. Scale bar 5 μm. Notes: (A) and (B) Reprinted from C-Mater Biol Appl, 99, Carvalho MS, Silva JC, Udangawa RN, et al. Co-culture cell-derived extracellular matrix loaded electrospun microfibrous scaffolds for bone tissue engineering. 479–490. Copyright 2019, with permission from Elsevier.226 |

Conclusion and Future Prospects

As an increasing number of drugs are investigated for osteogenic properties, it has become clear that various types of substances can be used to treat orthopedic diseases and promote osteogenic differentiation. Oral administration or injection may be used for systemic administration of some drugs, but this method is not ideal for targeting a bone defect site, and some serious side effects may occur. Local administration by utilizing the implant method can concentrate the effect and avoid possible adverse reactions. However, these drugs with osteogenic potential have their own unique structures, which will be disturbed by the in vivo environment. For example, polypeptide proteins such as BMP and VEGF may be difficult to maintain their stable activity during loading into bone scaffolds and storage, resulting in drug waste and even potential toxicity. In addition, the problem of hydrophobicity of some natural pharmaceutical compounds also needs to be solved. The long period (weeks to months) of orthopedic diseases forces drug-loaded bone scaffolds to be designed for high drug loading and sustained release. Or load different drugs and release them at different release gradients to meet the osteogenic needs of each stage. These are undoubtedly a huge challenge. This review discusses drug-loaded bone scaffolds, hydrogels, cements, etc., formed from natural/synthetic polymers and inorganic substances such as calcium phosphate, calcium sulfate, and mesoporous silica. These materials all have suitable mechanical properties, degradability and biocompatibility. They mimic the natural bone environment with a porous structure, which facilitates angiogenesis and cell adhesion to the growth matrix. Therapeutic drugs are bound to different biomaterials according to their properties, such as the strong charge interaction between the scaffold and the drug and the immobilization of the drug on the surface of the scaffold by covalent bonds. Drug delivery systems may also be constructed with nanoparticles such as microspheres. From a broader perspective, fields such as medicine, chemistry, materials science, and pathology are involved in the development of effective strategies to repair critical-sized bone defects, which is a unique characteristic of bone tissue engineering.

However, most recent studies only involve in vitro or animal models and have not been clinically proven to be effective for patients. In addition, due to the complex operation process of some strategies, the reproducibility and stability of the entire drug-loaded bone scaffold system need to be carefully considered. Difficulties in large-scale production and testing also hinder commercialization. It is worth mentioning that 3D printing technology provides unprecedented opportunities for bone tissue engineering. It can flexibly construct implants that adapt to each individual patient and can act as a scaffold to control drug delivery. This undoubtedly demonstrates the great potential of 3D printing in drug delivery and tissue engineering for orthopedic applications. Although 3D printing still has some shortcomings, such as difficult to control the fine structure and the hardness of the material is not suitable for cell growth. In the future, with the development of modern bone tissue engineering technology, innovative bone transplantation programs and treatment strategies will emerge, opening up a new era of dynamic research.

Acknowledgments

This work was financially supported by the Science and Technology Program of Guangzhou, China (NO.202103000089) the Guangdong Demonstration Base for Joint Cultivation of Postgraduates (2019), the Science Foundation for Distinguished Young Scholars of Guangdong (2020B1515020026).

Disclosure

Qishi Che is affiliated with Guangzhou Rainhome Pharm & Tech Co., Ltd. The authors report no other conflicts of interest in this work.

References

1. Chande S, Bergwitz CJNr C. Role of phosphate sensing in bone and mineral metabolism. Nat Rev Endocrinol. 2018;14(11):637–655. doi:10.1038/s41574-018-0076-3

2. Farokhi M, Mottaghitalab F, Shokrgozar M, Ou K, Mao C, Hosseinkhani HJ. Importance of dual delivery systems for bone tissue engineering. J Control Release. 2016;225:152–169. doi:10.1016/j.jconrel.2016.01.033

3. Qi JQ, Yu TQ, Hu BY, Wu HW, Ouyang HW. Current biomaterial-based bone tissue engineering and translational medicine. Review. Int J Mol Sci. 2021;22(19):

4. Bose S, Sarkar NJ. Natural medicinal compounds in bone tissue engineering. Trends Biotechnol. 2020;38(4):404–417. doi:10.1016/j.tibtech.2019.11.005

5. Kashirina A, Yao Y, Liu Y, Leng JJ. Biopolymers as bone substitutes: a review. Biomater Sci. 2019;7(10):3961–3983. doi:10.1039/c9bm00664h

6. Amini Z, Lari R. A systematic review of decellularized allograft and xenograft-derived scaffolds in bone tissue regeneration. Review. Tissue Cell. 2021;69:101494. doi:10.1016/j.tice.2021.101494

7. Nikolaou VS, Giannoudis PV. History of osteochondral allograft transplantation. Article. Inj Int J Care Inj. 2017;48(7):1283–1286. doi:10.1016/j.injury.2017.05.005

8. Guo L, Liang Z, Yang L, et al. The role of natural polymers in bone tissue engineering. J J Control Release. 2021;338:571–582. doi:10.1016/j.jconrel.2021.08.055

9. Li Z, Du T, Ruan C, Niu X. Bioinspired mineralized collagen scaffolds for bone tissue engineering. Bioact Mater. 2021;6(5):1491–1511. doi:10.1016/j.bioactmat.2020.11.004

10. Qin D, Wang N, You X, Zhang A, Chen X, Liu Y. Collagen-based biocomposites inspired by bone hierarchical structures for advanced bone regeneration: ongoing research and perspectives. Biomater Sci. 2022;10(2):318–353. doi:10.1039/d1bm01294k

11. Wang Z, Wang Y, Yan J, et al. Pharmaceutical electrospinning and 3D printing scaffold design for bone regeneration. Adv Drug Deliv Rev. 2021;174:504–534. doi:10.1016/j.addr.2021.05.007

12. Bow A, Anderson D, Dhar M. Commercially available bone graft substitutes: the impact of origin and processing on graft functionality. Drug Metab Rev. 2019;51(4):533–544. doi:10.1080/03602532.2019.1671860

13. Sohn H, JJBr O. Review of bone graft and bone substitutes with an emphasis on fracture surgeries. Biomater Res. 2019;23:9. doi:10.1186/s40824-019-0157-y

14. Hou Y, Xie W, Achazi K, et al. Injectable degradable PVA microgels prepared by microfluidic technology for controlled osteogenic differentiation of mesenchymal stem cells. Acta Biomater. 2018;77:28–37. doi:10.1016/j.actbio.2018.07.003

15. Suliman S, Sun Y, Pedersen TO, et al. In vivo host response and degradation of copolymer scaffolds functionalized with nanodiamonds and bone morphogenetic protein 2. Adv Healthc Mater. 2016;5(6):730–742. doi:10.1002/adhm.201500723

16. Yao Q, Liu Y, Selvaratnam B, Koodali RT, Sun H. Mesoporous silicate nanoparticles/3D nanofibrous scaffold-mediated dual-drug delivery for bone tissue engineering. J Control Release. 2018;279:69–78. doi:10.1016/j.jconrel.2018.04.011

17. Paris J, Lafuente-Gómez N, Cabañas M, Román J, Peña J, Vallet-Regí M. Fabrication of a nanoparticle-containing 3D porous bone scaffold with proangiogenic and antibacterial properties. Acta Biomater. 2019;86:441–449. doi:10.1016/j.actbio.2019.01.013

18. Chen S, Shi Y, Zhang X, Ma J. Evaluation of BMP-2 and VEGF loaded 3D printed hydroxyapatite composite scaffolds with enhanced osteogenic capacity in vitro and in vivo. Mater Sci Eng C Mater Biol Appl. 2020;112:110893. doi:10.1016/j.msec.2020.110893

19. De-Paula MMM, Afewerki S, Viana BC, Webster TJ, Lobo AO, Marciano FR. Dual effective core-shell electrospun scaffolds: promoting osteoblast maturation and reducing bacteria activity. Mater Sci Eng C Mater Biol Appl. 2019;103:109778. doi:10.1016/j.msec.2019.109778

20. Chu YS, Wong PC, Jang JS, Chen CH, Wu SH. Combining Mg-Zn-Ca bulk metallic glass with a mesoporous silica nanocomposite for bone tissue engineering. Pharmaceutics. 2022;14(5). doi:10.3390/pharmaceutics14051078

21. Rastegar A, Mahmoodi M, Mirjalili M, Nasirizadeh N. Platelet-rich fibrin-loaded PCL/chitosan core-shell fibers scaffold for enhanced osteogenic differentiation of mesenchymal stem cells. Article. Carbohydr Polym. 2021;269:

22. Filova E, Rampichova M, Litvinec A, et al. A cell-free nanofiber composite scaffold regenerated osteochondral defects in miniature pigs. Int J Pharm. 2013;447(1–2):139–149. doi:10.1016/j.ijpharm.2013.02.056

23. Chen Y, Wu T, Huang S, et al. Sustained release SDF-1alpha/TGF-beta1-loaded silk fibroin-porous gelatin scaffold promotes cartilage repair. ACS Appl Mater Interfaces. 2019;11(16):14608–14618. doi:10.1021/acsami.9b01532

24. Monteiro N, Ribeiro D, Martins A, et al. Instructive nanofibrous scaffold comprising runt-related transcription factor 2 gene delivery for bone tissue engineering. Article. ACS Nano. 2014;8(8):8082–8094. doi:10.1021/nn5021049

25. Li T, Peng MZ, Yang ZZ, et al. 3D-printed IFN-gamma-loading calcium silicate-beta-tricalcium phosphate scaffold sequentially activates M1 and M2 polarization of macrophages to promote vascularization of tissue engineering bone. Article. Acta Biomater. 2018;71:96–107. doi:10.1016/j.actbio.2018.03.012

26. Wang CZ, Wang YH, Lin CW, et al. Combination of a bioceramic scaffold and simvastatin nanoparticles as a synthetic alternative to autologous bone grafting. Article. Int J Mol Sci. 2018;19(12):

27. Venkatesan N, Liyanage ADT, Castro-Nunez J, et al. Biodegradable polymerized simvastatin stimulates bone formation. Acta Biomater. 2019;93:192–199. doi:10.1016/j.actbio.2019.04.059

28. Chen L, Tang Y, Zhao K, et al. Sequential release of double drug (graded distribution) loaded gelatin microspheres/PMMA bone cement. J Mater Chem B. 2021;9(2):508–522. doi:10.1039/d0tb01452d

29. Daryasari MP, Telgerd MD, Karami MH, et al. Poly-l-lactic acid scaffold incorporated chitosan-coated mesoporous silica nanoparticles as pH-sensitive composite for enhanced osteogenic differentiation of human adipose tissue stem cells by dexamethasone delivery. Article. Artif Cells Nanomed Biotechnol. 2019;47(1):4020–4029. doi:10.1080/21691401.2019.1658594

30. Zhou X, Liu P, Nie W, et al. Incorporation of dexamethasone-loaded mesoporous silica nanoparticles into mineralized porous biocomposite scaffolds for improving osteogenic activity. Int J Biol Macromol. 2020;149:116–126. doi:10.1016/j.ijbiomac.2020.01.237

31. Han XY, Sun MJ, Chen B, et al. Lotus seedpod-inspired internal vascularized 3D printed scaffold for bone tissue repair. Article. Bioact Mater. 2021;6(6):1639–1652. doi:10.1016/j.bioactmat.2020.11.019

32. Cheng X, Cheng G, Xing X, et al. Controlled release of adenosine from core-shell nanofibers to promote bone regeneration through STAT3 signaling pathway. J Controlled Release. 2020;319:234–245. doi:10.1016/j.jconrel.2019.12.048

33. Sumathra M, Munusamy MA, Alarfaj AA, Rajan M. Osteoblast response to vitamin D3 loaded cellulose enriched hydroxyapatite Mesoporous silica nanoparticles composite. Biomed Pharmacother. 2018;103:858–868. doi:10.1016/j.biopha.2018.04.078

34. Li Y, Li Q, Li H, et al. An effective dual-factor modified 3D-printed PCL scaffold for bone defect repair. J Biomed Mater Res B Appl Biomater. 2020;108(5):2167–2179. doi:10.1002/jbm.b.34555

35. Li Y, Bai YJ, Pan JJ, et al. A hybrid 3D-printed aspirin-laden liposome composite scaffold for bone tissue engineering. Article. J Mat Chem B. 2019;7(4):619–629. doi:10.1039/c8tb02756k

36. Monavari M, Homaeigohar S, Fuentes-Chandía M, et al. 3D printing of alginate dialdehyde-gelatin (ADA-GEL) hydrogels incorporating phytotherapeutic icariin loaded mesoporous SiO-CaO nanoparticles for bone tissue engineering. Mater Sci Eng. 2021;131:112470. doi:10.1016/j.msec.2021.112470

37. Lai Y, Cao H, Wang X, et al. Porous composite scaffold incorporating osteogenic phytomolecule icariin for promoting skeletal regeneration in challenging osteonecrotic bone in rabbits. Biomaterials. 2018;153:1–13. doi:10.1016/j.biomaterials.2017.10.025

38. Jin S, Gao J, Yang R, et al. A baicalin-loaded coaxial nanofiber scaffold regulated inflammation and osteoclast differentiation for vascularized bone regeneration. Bioact Mater. 2022;8:559–572. doi:10.1016/j.bioactmat.2021.06.028

39. Kamali A, Oryan A, Hosseini S, et al. Cannabidiol-loaded microspheres incorporated into osteoconductive scaffold enhance mesenchymal stem cell recruitment and regeneration of critical-sized bone defects. Mater Sci Eng C Mater Biol Appl. 2019;101:64–75. doi:10.1016/j.msec.2019.03.070

40. Sarkar N, Bose S. Liposome-encapsulated curcumin-loaded 3D printed scaffold for bone tissue engineering. ACS Appl Mat Interfaces. 2019;11(19):17184–17192. doi:10.1021/acsami.9b01218

41. Ji C, Bi L, Li J, Fan J. Salvianolic acid B-loaded chitosan/hydroxyapatite scaffolds promotes the repair of segmental bone defect by angiogenesis and osteogenesis. Int J Nanomed. 2019;14:8271–8284. doi:10.2147/ijn.S219105

42. Liu Y, Wang R, Chen S, et al. Heparan sulfate loaded polycaprolactone-hydroxyapatite scaffolds with 3D printing for bone defect repair. Int J Biol Macromol. 2020;148:153–162. doi:10.1016/j.ijbiomac.2020.01.109

43. Rumian Ł, Tiainen H, Cibor U, et al. Ceramic scaffolds enriched with gentamicin loaded poly(lactide-co-glycolide) microparticles for prevention and treatment of bone tissue infections. Mater Sci Eng C Mater Biol Appl. 2016;69:856–864. doi:10.1016/j.msec.2016.07.065

44. Cheng T, Qu H, Zhang G. Osteogenic and antibacterial properties of vancomycin-laden mesoporous bioglass/PLGA composite scaffolds for bone regeneration in infected bone defects. Artif Cells Nanomed Biotechnol. 2018;46(8):1935–1947. doi:10.1080/21691401.2017.1396997

45. Ferreira M, Rzhepishevska O, Grenho L, et al. Levofloxacin-loaded bone cement delivery system: highly effective against intracellular bacteria and Staphylococcus aureus biofilms. Int J Pharm. 2017;532(1):241–248. doi:10.1016/j.ijpharm.2017.08.089

46. Wang H, Liu J, Tao S, et al. Tetracycline-grafted PLGA nanoparticles as bone-targeting drug delivery system. Int J Nanomed. 2015;10:5671–5685. doi:10.2147/ijn.S88798

47. Ghosh S, Wu V, Pernal S, Uskoković V. Self-setting calcium phosphate cements with tunable antibiotic release rates for advanced antimicrobial applications. ACS Appl Mater Interfaces. 2016;8(12):7691–7708. doi:10.1021/acsami.6b01160

48. Bigham A, Aghajanian AH, Behzadzadeh S, et al. Nanostructured magnetic Mg2SiO4-CoFe2O4 composite scaffold with multiple capabilities for bone tissue regeneration. Mater Sci Eng C Mater Biol Appl. 2019;99:83–95. doi:10.1016/j.msec.2019.01.096

49. Liang W, Gao M, Lou J, et al. Integrating silicon/zinc dual elements with PLGA microspheres in calcium phosphate cement scaffolds synergistically enhances bone regeneration. J Mater Chem B. 2020;8(15):3038–3049. doi:10.1039/c9tb02901j

50. Rohnke M, Pfitzenreuter S, Mogwitz B, et al. Strontium release from Sr(2+)-loaded bone cements and dispersion in healthy and osteoporotic rat bone. J Control Release. 2017;262:159–169. doi:10.1016/j.jconrel.2017.07.036

51. Liao F, Peng XY, Yang F, Ke QF, Zhu ZH, Guo YP. Gadolinium-doped mesoporous calcium silicate/chitosan scaffolds enhanced bone regeneration ability. Article. Mater Sci Eng C Mater Biol Appl. 2019;104:

52. Peng XY, Hu M, Liao F, et al. La-Doped mesoporous calcium silicate/chitosan scaffolds for bone tissue engineering. Article. Biomater Sci. 2019;7(4):1565–1573. doi:10.1039/c8bm01498a

53. Kurtuldu F, Mutlu N, Michalek M, et al. Cerium and gallium containing mesoporous bioactive glass nanoparticles for bone regeneration: bioactivity, biocompatibility and antibacterial activity. Mater Sci Eng C Mater Biol Appl. 2021;124:112050. doi:10.1016/j.msec.2021.112050

54. Singh B, Pramanik K. Generation of bioactive nano-composite scaffold of nanobioglass/silk fibroin/carboxymethyl cellulose for bone tissue engineering. J Biomater Sci Polym Ed. 2018;29(16):2011–2034. doi:10.1080/09205063.2018.1523525

55. Lin CY, Chang YH, Li KC, et al. The use of ASCs engineered to express BMP2 or TGF-beta3 within scaffold constructs to promote calvarial bone repair. Biomaterials. 2013;34(37):9401–9412. doi:10.1016/j.biomaterials.2013.08.051

56. Tevlin R, desJardins-Park H, Huber J, DiIorio SE, Longaker MT, Wan DC. Musculoskeletal tissue engineering: adipose derived stromal cell implementation for the treatment of osteoarthritis. Biomaterials. 2022;286:121544. doi:10.1016/j.biomaterials.2022.121544

57. Qi X, Zhang J, Yuan H, et al. Exosomes secreted by human-induced pluripotent stem cell-derived mesenchymal stem cells repair critical-sized bone defects through enhanced angiogenesis and osteogenesis in osteoporotic rats. Int J Biol Sci. 2016;12(7):836–849. doi:10.7150/ijbs.14809

58. Xie J, Peng C, Zhao Q, et al. Osteogenic differentiation and bone regeneration of iPSC-MSCs supported by a biomimetic nanofibrous scaffold. Acta Biomater. 2016;29:365–379. doi:10.1016/j.actbio.2015.10.007

59. Zhang M, Shi J, Xie M, et al. Recapitulation of cartilage/bone formation using iPSCs via biomimetic 3D rotary culture approach for developmental engineering. Biomaterials. 2020;260:120334. doi:10.1016/j.biomaterials.2020.120334

60. Evans ND, Gentleman E, Chen X, Roberts CJ, Polak JM, Stevens MM. Extracellular matrix-mediated osteogenic differentiation of murine embryonic stem cells. Biomaterials. 2010;31(12):3244–3252. doi:10.1016/j.biomaterials.2010.01.039

61. Gamie Z, Tran GT, Vyzas G, et al. Stem cells combined with bone graft substitutes in skeletal tissue engineering. Review. Expert Opin Biol Ther. 2012;12(6):713–729. doi:10.1517/14712598.2012.679652

62. Liu Z, Chang H, Hou Y, et al. Lentivirus-mediated microRNA-26a overexpression in bone mesenchymal stem cells facilitates bone regeneration in bone defects of calvaria in mice. Mol Med Rep. 2018;18(6):5317–5326. doi:10.3892/mmr.2018.9596

63. Deng Y, Zhou H, Gu P, Fan X. Repair of canine medial orbital bone defects with miR-31-modified bone marrow mesenchymal stem cells. Invest Ophthalmol Vis Sci. 2014;55(9):6016–6023. doi:10.1167/iovs.14-14977