Back to Journals » Drug Design, Development and Therapy » Volume 12

Current development of biodegradable polymeric materials for biomedical applications

Authors Song R , Murphy M , Li C, Ting K, Soo C, Zheng Z

Received 13 February 2018

Accepted for publication 9 July 2018

Published 24 September 2018 Volume 2018:12 Pages 3117—3145

DOI https://doi.org/10.2147/DDDT.S165440

Checked for plagiarism Yes

Review by Single anonymous peer review

Peer reviewer comments 5

Editor who approved publication: Professor Anastasios Lymperopoulos

Richard Song,1 Maxwell Murphy,1 Chenshuang Li,1 Kang Ting,1–3 Chia Soo,2 Zhong Zheng1

1Division of Growth and Development, Section of Orthodontics, School of Dentistry, University of California, Los Angeles, Los Angeles, CA, USA; 2UCLA Department of Surgery and Department of Orthopaedic Surgery and The Orthopaedic Hospital Research Center, University of California, Los Angeles, Los Angeles, CA, USA; 3UCLA Department of Bioengineering, School of Engineering, University of California, Los Angeles, Los Angeles, CA, USA

Abstract: In the last half-century, the development of biodegradable polymeric materials for biomedical applications has advanced significantly. Biodegradable polymeric materials are favored in the development of therapeutic devices, including temporary implants and three-dimensional scaffolds for tissue engineering. Further advancements have occurred in the utilization of biodegradable polymeric materials for pharmacological applications such as delivery vehicles for controlled/sustained drug release. These applications require particular physicochemical, biological, and degradation properties of the materials to deliver effective therapy. As a result, a wide range of natural or synthetic polymers able to undergo hydrolytic or enzymatic degradation is being studied for biomedical applications. This review outlines the current development of biodegradable natural and synthetic polymeric materials for various biomedical applications, including tissue engineering, temporary implants, wound healing, and drug delivery.

Keywords: tissue engineering, drug delivery, wound healing, natural biomaterials, synthetic biomaterials

Introduction

A biomaterial can be defined as a material intended to interface with biological systems in order to evaluate, treat, augment, or replace any tissue, organ, or function of the body.1 The global market for implantable biomaterials was worth nearly $75.1 billion in 2013. This market is expected to grow at a compound annual growth rate (CAGR) of 6.7% between 2014 and 2019, resulting in a $79.1 billion global market in 2014 and a $109.5 billion global market in 2019.2 Although biomedical applications of natural enzymatically degradable polymers date back thousands of years, the application of synthetic biodegradable polymers began only in the second half of the 1960s.3 Considering their advantages over biostable materials in terms of long-term biocompatibility along with the technical and ethical issues accompanying revision surgeries, investigations into the application of biodegradable biomaterials rather than permanent prosthetic devices for assisting in tissue repair and regeneration has vigorously increased recently.4–6 As a result, polymeric biomaterials are quickly replacing other material classes, such as metals, alloys, and ceramics, for use as biomaterials due to their versatility.3–5 Within the global implantable biomaterial market, the polymeric biomaterials sector is expected to show the highest growth, at a CAGR of 22.1%, because of its promising potential in a wide range of biomedical applications.2 With this in mind, the aim of this review is to highlight the most often studied polymeric biomaterials and underscore their immense potential in the areas of drug design, development, and therapy.

A critical requirement for a biomaterial is biocompatibility – the ability of a material to function with an appropriate host response in a specific application.1 Many biological and physicochemical characteristics of an implant material govern the host tissue response to the material. For instance, molecular weight, solubility, hydrophilicity/hydrophobicity, surface energy, material chemistry, mechanism of degradation and/or erosion, lubricity, and shape and structure of the implant can all influence the material’s biocompatibility.7 Importantly, a biodegradable biomaterial requires excellent biocompatibility over time because the physicochemical, mechanical, and biological properties of a biodegradable biomaterial will differ with time and, thus, the resulting degradation products can possess varying levels of tissue compatibility as compared with the initial parent material. An ideal biodegradable biomaterial should have degradation products that are nontoxic and easily metabolized and cleared from the body.

In addition to biocompatibility, several other important properties must be considered when choosing a biodegradable biomaterial. First, the degradation time of the biomaterial should coincide with the regeneration and/or healing process to ensure proper remodeling of the tissue. Second, the biomaterial must maintain suitable permeability and processability for its intended application. Finally, the mechanical properties of the biomaterial should be sufficient to promote regeneration during the patient’s everyday activities, and any change in mechanical properties due to degradation should preserve compatibility with the healing or regeneration process.

Given the complexity of the human body and the scope of applications that polymeric biomaterials are currently utilized for, no single polymeric system can be considered the ideal biomaterial for all medical applications. Thus, recent advances in biodegradable biomaterial synthesis have been directed toward developing and synthesizing polymers with properties tailored for specific biomedical applications. Moreover, current developments incorporating multifunctional and combinatorial approaches in biomaterial design have accelerated the innovation of novel biodegradable biomaterials. Another hotspot in biomaterials research is the development of therapeutic devices, including temporary prostheses, three-dimensional (3D) porous scaffolds for tissue engineering, and delivery vehicles for pharmacological applications. Most recently, 3D bioprinting has also been acknowledged, and preliminary data collection for biomaterial use as potential bio-ink for printing of 3D scaffolds have begun. Because biodegradable biomaterials exhibit a variety of biological and physicochemical properties and, therefore, can replicate the properties of different tissues, these materials are assessed for use as 1) large implants, including bone screws, bone plates, and contraceptive reservoirs; 2) small implants, in the form of sutures and staples; 3) plain membranes for guided tissue regeneration; and 4) porous structures or multifilament meshes for tissue engineering.8 Moreover, by properly engineering the structure and degradation parameters, these biodegradable materials can be used to generate micro- or nanoscale drug-delivery vehicles for controlled drug delivery in an erosive or diffusive manner, or as a combination of both.9

Because of the interest aroused in the areas demanding biodegradable biomaterials, including regenerative medicine, tissue engineering, controlled drug delivery, gene therapy, and nanotechnology, there has been a robust expansion of biomedical applications of synthetic biodegradable polymers and analogous natural polymers, and our review will focus on exploring the most current development of these polymers for biomedical applications in these fields. Although many other reviews have focused on the topic of biodegradable biomaterials for medical use, to our best knowledge, there has not been a review published within the past 5 years that covers as much breadth as our review does about the development of the most commonly investigated biodegradable polymeric biomaterials in the fields of drug delivery, tissue engineering, and wound application.

Natural biodegradable polymeric biomaterials

Biodegradable biomaterials can be roughly divided into two categories – natural and synthetic – based on their source and whether they are composed of naturally occurring extracellular matrix (ECM). Natural biodegradable polymeric biomaterials generally include proteins (collagen, fibrin, silk, etc.), and polysaccharides (starch, alginate, chitin/chitosan, hyaluronic acid derivatives, etc.).10–12 Furthermore, a family of native polyesters – polyhydroxyalkanoates (PHA) – has been recognized as natural biodegradable biomaterials and, more recently, sundew adhesives (natural polysaccharide-based hydrogels) and ivy nanoparticles (macromolecular compositions of nanospherical arabinogalactan proteins) have garnered more attention for their ability to create effective nanocomposite adhesives and for their potential use as nano-carriers in drug delivery, respectively.13,14

Collagen

As the most prevalent protein in the human body, collagen offers physical support to tissues by inhabiting the intercellular space, acting not only as native structural support for organizing cells within connective tissues, but also as a mobile, dynamic, and flexible substance essential to cellular behaviors and tissue function.15 Generally, collagen is a rod-type polymer approximately 300-nm long with a molecular weight of approximately 300 kDa. Free amino acids in the body are synthesized into subunit chains of collagen, which then undergo transcription, translation, and post-translational modification processes in suitable cells such as osteoblasts and fibroblasts.13 More than 22 different types of collagen have been identified in the human body, with types I–IV being the most common, and type I collagen being the single greatest abundant protein present in mammals.15 Collagen undergoes enzymatic degradation within the body by a diverse set of enzymes, such as matrix metalloproteinases and collagenases, to yield its corresponding amino acids. Due to its enzymatic degradability; unique mechanical, biological, and physicochemical properties; nontoxicity; and high tensile strength, collagen has been widely studied for biomedical applications.16,17

Collagen plays a critical role in preserving the biological and structural integrity of the ECM and is highly dynamic, undergoing continuous remodeling for proper physiologic functions. For most soft and hard connective tissues (eg, blood vessels, cornea, skin, tendon, cartilage, and bone), collagen fibrils and their networks function through their highly organized 3D structure. Tissue regeneration attempts to repair both the structural integrity and the intricate remodeling process of the native ECM, particularly restoring the delicate collagen networks under which normal physiologic regeneration occurs; thus, recent efforts have been focused on replacing native collagen-based ECM by developing novel biomaterials that imitate its intricate fibrillar architecture and function as cell scaffolding. Animal-derived and recombinant collagens, especially type I collagen, are recognized as one of the most valuable biomaterials available and are now extensively used for tissue engineering, drug delivery, and cosmetic surgery. For example, a composite of fibrillar collagen, hydroxyapatite, and tricalcium phosphate (Collagraft®, Angiotech Pharmaceuticals) has been approved by the United States Food and Drug Administration (FDA) as a biodegradable synthetic bone graft substitute.18

The main sources of collagen presently utilized for biomedical applications are bovine or porcine skin and bovine or equine Achilles tendons. They are utilized in either their native fibrillar form or after denaturation in various fabricated forms, such as sponges, sheets, plugs, and pellets. Collagen-based materials have been successfully used for skin repair.19 For example, Promogran® (Systagenix) – a spongy collagen matrix containing oxidized cellulose – is available in the USA and Europe for treatment of diabetic and ulcer wounds.20 Similarly, an FDA-approved bilayer skin substitute (Integra® Dermal Regeneration Template, Integra LifeSciences) composed of a dermal layer of cross-linked bovine collagen and glycosaminoglycans (GAGs) as well as an epidermal layer of polysiloxane, which deposits ECM components, is in the market for full-thickness or deep partial thickness thermal injury. Moreover, these skin substitutes constructed from cell-seeded collagens have been widely commercialized (eg, Apligraf®, Organogenesis, Inc.) and (OrCel™, Ortec International Inc.). Interestingly, type I collagen sponges have also been used to engineer patellar tendons in rabbits under different culture conditions.21–23 Using the collagen sponge combined with bone marrow-derived mesenchymal stem cells, Juncosa-Melvin et al demonstrated that the engineered tendon tissue attained almost 75% of the mechanical properties of native tendon.22 In other studies, collagen has also been successfully used as a scaffold in nerve and bladder engineering.24–26 Additionally, a suture-free, 3D-collagen matrix graft – DuraGen® (Integra LifeSciences) – has been developed for spinal dural repair and regeneration and is currently approved by the FDA.27

Collagen is, furthermore, a key initiator of the coagulation cascade and, therefore, it has been successfully developed as a hemostatic agent due to its high thrombogenicity. Multiple collagen-based hemostats are currently available or undergoing clinical trials for a variety of surgical indications; these include Sulzer-Spine® Tech’s sealants composed of bovine collagen and bovine thrombin for cardiovascular and spinal surgical procedures; Floseal® (Baxter Healthcare), a high-viscosity gel hemostatic agent composed of collagen-derived particles and topical bovine-derived thrombin; and CoStasis® Surgical Hemostat (Cohesion Technologies), which consists of bovine thrombin and bovine microfibrillar collagen combined with autologous plasma.

With regard to drug delivery, collagen has been notably studied for the delivery of low-molecular-weight drugs, proteins, genes, and plasmids. Currently, a few collagen-based gentamicin-delivery vehicles are available in the global market (eg, Sulmycin®-Implant and Collatamp®-G, Innocoll Pharmaceuticals Ltd). These delivery systems permit a sustained local delivery of antibiotics with limited systemic exposure. Moreover, another product, Septocoll® (Biomet), achieved prolonged collagen delivery by incorporating two gentamicin salts possessing different solubility, and has been approved for infection prevention.28 More recently, a new biodegradable, collagen-based chlorhexidine chip has been shown to provide a longer, more sustained release of chlorhexidine in the confines of the periodontal pocket as compared to simple subgingival irrigation of chlorhexidine. The constant outflow of the gingival crevicular fluid from the periodontal pocket (up to 40 times an hour) renders subgingival irrigation of chlorhexidine useless in delivering significant antimicrobial benefits, reduction in probing depths, and clinical attachment level gain to manage chronic periodontitis; however, the use of a collagen-based release vehicle allows for a controlled delivery of chlorhexidine to achieve the intended pharmaceutical effects.29 Furthermore, current clinical trials are investigating cross-linked, absorbable collagen sponges as protein-carrier vehicles. Prolonged release of bioactive proteins, such as recombinant human bone morphogenic protein-2 (rhBMP-2), have been reported when utilized in conjunction with collagen matrices due to desirable interactions of the collagen matrix with the protein.30 This combination product is approved by the FDA for simultaneous use with a titanium interbody spine fusion cage for anterior lumbar spinal fusion (InFUSE® Bone Graft/LT-CAGE® Lumbar Tapered Fusion Device, Medtronic Spinal and Biologics), and a similar product InductOs® (Medtronic Spinal and Biologics) is approved in Europe for the treatment of acute tibial fractures in adult patients. Additionally, a recent study reported that the delivery of rhBMP-2 by an absorbable collagen sponge stimulated bone reconstruction in advanced alveolar ridge defects.31 Aside from its use as a protein-delivery vehicle, collagen has been demonstrated to retain gene vector/plasmid DNA whereas simultaneously protecting it from enzymatic or immunological reactions of the body, which underscores its potential in gene and plasmid DNA delivery.32

One disadvantage of these collagen-based biomaterials is their mild immunogenicity due to the antigenic sites in the central helix and the composition of the terminal region, which significantly limits their clinical application.33 The immune response varies depending on the processing techniques, site of implantation, and species from which the collagen has been isolated.34 Other disadvantages of animal-derived collagen include the varying physicochemical and degradation properties, the high cost of pure collagen, and the allogeneic or xenogeneic sources, which increase the risk of infectious disease transmission. In response to these limitations, present investigations have directed focus toward recombinant systems that can produce human-based collagen.35,36 Several potentially useful systems already exist for large-scale production and purification of recombinant collagen, such as yeasts, transgenic animals, and, most recently, Escherichia coli.37,38 Because the amino acid sequence of recombinant collagen can be directly modified, it is possible to make controlled, targeted collagen products for specific applications, thereby diversifying and increasing the potential of collagen-based products.39 However, recombinant collagen is unable to undergo natural posttranslational modification and, thus, may lack critical biological activities of native tissue.33 This lack of posttranslational modification means that, despite its flexibility in creating countless different amino acid sequences for different targeted applications, recombinant collagens may not be suitable for many biomedical applications, especially those that require stability and strength such as heart valves. Furthermore, the commercially available recombinant collagens are still expensive to produce and, thus far, only limited amounts are available.39

Collagen as a biomaterial has already seen significant use in several specific applications in skin repair, hemostatic agents, and drug delivery, but its slight immunogenicity, high cost, and varying physicochemical and degradation properties prevent further expansion of collagen-based biomaterials. Although recombinant collagens have the potential to catapult collagen-based biomaterials for widespread use, significant limitations such as their lack of posttranslational modification will need to be continually studied for them to have any noticeable impact for use as a biomaterial.

Gelatin

Gelatin is a natural biopolymer derived from collagen via controlled alkaline, acid, or enzymatic hydrolysis.40 As a result of its biological origin, it has excellent biodegradability and biocompatibility and because it is widely available, gelatin is a relatively low-cost polymer.40 Gelatin has been used in medical and pharmaceutical fields as a matrix for implants, and as stabilizers in vaccines such as measles, mumps, and rubella.41 Moreover, gelatin is water permeable and soluble in water and has multifunctional properties as a drug-delivery carrier.42 Gelatin’s mechanical properties, swelling behavior, thermal properties, and many other physiochemical properties can be dependent upon the collagen source, extraction method, amount of thermal denatured employed, and the degree of cross-linking, thereby making gelatin a very versatile polymer.43 Furthermore, its ability to produce a thermoreversible gel makes it a very good candidate as a targeted drug-delivery carrier and, as a result, gelatin can be utilized to develop specific drug-release profiles, allowing for a broad range of applications in drug delivery.43

Gelatin is a versatile biopolymer that traditionally enabled the design of several different drug carrier systems, such as microparticles, nanoparticles, fibers, and hydrogels.44 Each of these different systems has certain properties that make them particularly suitable for drug delivery.44 For example, gelatin microparticles are popular for serving as vehicles for cell amplification and delivery of large bioactive molecules, and gelatin nanoparticles are better for drug delivery to the brain or in intravenous delivery.44 Recently, a novel and relatively simple method was discovered for producing gelatin microparticles which allow for very high protein- and drug-loading efficiencies.45 In the experiment, bovine serum albumin (BSA) was added at a 0.1%–0.4% gelatin concentration, resulting in a gelatin solution.45 The solution was freeze-dried and the resulting spongy membranes were hardened with liquid nitrogen and subsequently ground to a powder, producing BSA-loaded microparticles in random forms and shapes.45 These microparticles were then incorporated into porous scaffolds constructed of polylactide (PLLA) and polycaprolactone (PCL).45 The in vitro release profile of the protein from the particles alone and from the particle-incorporated scaffolds demonstrated up to 90% protein-loading efficiency, showing that BSA-loaded microparticles in conjunction with particle-incorporated scaffolds for growth factor release may be possible for application in bone tissue engineering.45 Another study studied the in vitro efficacy and toxicity of incorporating polyenes into electrospun gelatin fiber mats as a topical antifungal application.46 The research group found that polyene-loaded antifungal gelatin mats displayed better antifungal activity than using traditional electrospun gelatin fiber mats.46 Furthermore, they found that polyenes stabilized the triple helical conformation of gelatin whereas gelatin decreased the hemolytic activity of polyenes, making polyene antifungal-loaded gelatin fiber mats a possibility in managing superficial skin infections in the future.46 Cohen et al studied novel tissue adhesives based on gelatin, with alginate as a polymeric additive, loaded with bupivacaine or ibuprofen for pain management.47 They found that the release of drugs from the adhesive matrix was primarily controlled by the gelatin/alginate bioadhesive’s characteristics, such as swelling and hydrophilic group concentrations that can be adjusted by changing the ratio of gelatin to alginate.47 Moreover, they found that the hydrophilicity and electrical interactions between bupivacaine and ibuprofen with the adhesive components had some effect on the release profile of the drug, and that incorporating bupivacaine improved the bonding strength of the adhesive due to its inert nature whereas ibuprofen decreased the bonding strength due to its reactive nature with the alginate/gelatin adhesive.47 Overall, the study shows that this loading bupivacaine in a gelatin/alginate bioadhesive can potentially be used for wound-closing applications.47

The primary advantages of gelatin are its biodegradability, availability, and cheap cost.44 Porcine skin-derived gelatin is the most popular source, followed by bovine skin, and bone.48 However, religious issues may arise, as porcine-derived products and bovine-derived products are forbidden in Judaism and Hinduism, respectively.48 In addition, there are health concerns over transmission of pathogenic vectors such as prions.48 Recombinant gelatins, however, can be utilized to overcome the disadvantages with animal tissue-derived materials.49 Currently, the primary use of gelatin is in the food, pharmaceutical, and photographic industries.49 In the biomedical field, gelatin is used in drug delivery and in some wound dressing and tissue-regeneration applications, but its use is heavily limited by its poor mechanical properties.49 These mechanical properties can be strengthened through physical cross-linking as well as chemical cross-linking due to a large number of functional side groups that gelatin possesses; however, agents used to stabilize cross-linked gelatin are often somewhat toxic to the human body.49 Research into improving gelatin’s mechanical properties will need to be investigated in the future for gelatin to have a promising future as a primary biomaterial; but, until then, the most likely incorporation of gelatin will be as a composite with other natural or synthetic biomaterials, or as a carrier for drug delivery.

Fibrin

Fibrin is a 360-kD fibrinogen-derivative biopolymer involved in the natural blood-clotting process, enhancing cell adhesion and proliferation.50 In addition to possessing excellent biodegradability and biocompatibility, fibrin exhibits high elastic and viscous properties; stiffens in response to shear, tension, or compression; and has excellent deformability.51 One of the first developed fibrin-based products was fibrin glue (fibrin sealant). Tissucol/Tisseel™ (Baxter Healthcare) and Beriplast HS/Beriplast P™ (CSL Behring) are the first-generation products of fibrin sealants marketed in Europe. Today, an expansive variety of products possessing different compositions and adhesive properties are available on the market. These products are broadly used for hemostasis and tissue-sealing applications in various surgical procedures, including neurosurgery and plastic and reconstructive surgery.52–54

Furthermore, fibrin has been utilized as a scaffold for the regeneration of numerous tissues, such as adipose tissue, bone, cardiac tissue, cartilage, muscle tissue, nervous tissue, ocular tissue, respiratory tissue, skin, tendons and ligaments, and vascular tissue as well as a carrier vehicle for bioactive molecules (drugs, antibiotics, or chemotherapy agents) due to its injectability and biodegradability.55–60 For instance, several studies have demonstrated that clinical application of fibrin significantly improved the healing of intrabony defects in chronic periodontitis.61,62 Further evidence suggests that proteins interact differently with fibrin clots and, as a result, several cross-linking techniques are presently being studied to control the release profile of bioactive molecules from the fibrin matrix.63 Additionally, fibrin matrices have been utilized as excellent cell-carrier vehicles. One successful example obtained by mixing keratinocytes with fibrin is Bioseed® (DCM Shriram Limited), a fibrin-based product used to treat chronic cutaneous wounds.

Fibrin is natural, highly available, implantable, inexpensive, easy to use, and has low fibrinogen concentrations. Due to its porous morphology, a fibrin scaffold system is adequate for cell attachment, proliferation, differentiation,58,64 and as a release system of growth factors such as vascular endothelial growth factor and basic fibroblast growth factor (bFGF).60,65 Fibrin-immobilized growth factors have been shown to be continuously released for several days in a controlled manner, making it optimal for numerous tissue-engineering purposes.50 Thus, autologous fibrin could prevent the complications of techniques derived from the use of current commercial available fibrin products and should be further investigated. Fibrin-based scaffolds do have some limitations, such as weak mechanical strength and quick degradation rates; however, these properties have been shown to be improved by incorporating stronger natural and synthetic polymers, utilizing various cross-linking methods, and utilizing micro/nanospheres.50 Next-generation scaffolds will likely involve specific cell lines, combined with biomolecules and growth factors to accelerate and increase cell proliferation and differentiation on immobilized scaffolds for a variety of tissues, and fibrin-based drug-delivery carriers and tissue-engineered scaffolds, including the relatively recent scaffold development of fibrin microspheres, nanospheres, microfibers, microtubes, and porous sheets, all of which will play a big role in regenerative medicine.50

Hyaluronic acid (HA)

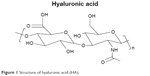

HA is an essential component of the ECM and its structural and biological properties mediate cellular signaling, morphogenesis, matrix organization, and wound repair.66,67 In 1943, HA was first isolated from the vitreous humor by Meyer and Palmer.68 HA is a member of the GAG family, which involves linear polysaccharides consisting of alternating units of N-acetyl-d-glucosamine and glucuronic acid ranging in size from 5,000 to 20,000,000 Daltons in vivo, and is present in almost every tissue in vertebrates. Native sources of HA include rooster combs, bovine vitreous humor, and synovial fluids.69 HA degradation occurs in the body through free radicals, such as nitric oxide and matrix metalloproteinases found in the ECM, and then undergoes endocytosis. Further digestion of HA by lysosomal enzymes results in mono- and disaccharides, which are then converted into ammonia, carbon dioxide, and water.69

| Figure 1 Structure of hyaluronic acid (HA). |

Recently, HA has become recognized as an important building block for the creation of new biomaterials for use in cell therapy, 3D cell culture, and tissue engineering.70–72 As HA is secreted at the early stage of wound healing, it has been extensively researched for wound-dressing applications.73,74 HA can be recognized by receptors on a variety of cells associated with tissue repair, and thus presents the capability to stimulate angiogenesis and to regulate injury-induced inflammation as a free radical scavenger.75 Moreover, HA promotes epithelial and mesenchymal cell migration and differentiation, making it vital for tissue repair.75 These properties combined with its immunoneutral potency make HA an ideal biomaterial for tissue engineering.75 Moreover, its aqueous solubility allows for modification of HA into various porous and 3D structures for drug delivery. For example, HYAFF®11 (Anika Therapeutics, Inc.), an HA-based product, is currently utilized as a carrier vehicle for a variety of growth factors, morphogens, and stem cells.76 In a comparative study, Hunt et al reported an improved healing response to rhBMP-2 delivered by HYAFF®11 than that delivered by an absorbable collagen sponge.76 A more recent study indicated that HA-based materials maintain the potential to replace collagen-based materials as injectable soft tissue fillers.77 With regard to tissue engineering, HA has been successfully incorporated into multiple complex systems. For example, HA-modified poly(D,L-lactic acid-co-glycolic acid) (PLGA) scaffolds were successful in inducing cartilage tissue formation in terms of type II collagen expression and tissue morphological characteristics.78 Additionally, high-molecular-weight viscous HA solutions (eg, AMVISC® and AMVISC® PLUS, Bausch & Lomb) currently function as vitreous humor substitutes and as protection for sensitive eye tissue during glaucoma surgery, cataract extraction, and corneal transplantation. Viscous HA solutions (eg, SYNVISC®, SanofiBiosurgery; and ORTHOVISC®, Anika Therapeutics, Inc.) are also clinically applied as synovial fluid substitutes to reduce pain and enhance joint mobility in patients with osteoarthritis.79

Moreover, HA derivatives, such as HA esters and cross-linked HA gels, have been thoroughly researched for wound dressing applications. Reports suggest that these chemical modifications significantly reduce the degradation of HA.69,80 For example, in the absence of enzymatic activity, benzyl HA esters undergo hydrolytic degradation via ester bonds, and the degradation time varies from 1 to 2 weeks to 2–3 months depending on the degree of esterification.69,80 Together, these studies underscore the potential of HA in combined systems for an array of biomedical applications, including tissue engineering, drug delivery, wound healing, and temporary implants.

Chitin/chitosan

Chitosan is another naturally derived biodegradable polysaccharide commonly used in tissue engineering.81 Chitosan is a derivative of chitin – the second most abundant natural polymer commonly found in the exoskeletons of crustacean and insects as well as the cells walls of fungi.81 Chitin is partially deacetylated to form chitosan, which is composed of glucosamine and N-acetyl glucosamine linked in a β(1–4) manner.82 The molecular weight and the degree of deacetylation, which are essential in assessing the characteristics of chitosan, are reliant on the source and production process.

Chitin and chitosan are biodegraded by human enzymes, such as lysozymes, which disrupt the linkage between acetylated units and degrades chitin/chitosan to oligosaccharides.83 The degradability of chitin/chitosan-based materials is essential for scaffold construction because it can influence cell behavior and tissue formation of the engineered construct.84 However, the low mechanical resistance of chitosan makes it disadvantageous to be used as a supporting material in tissue engineering.85 To create a better mechanical profile, cross-linking agents are used with functional reactive groups to allow for bridges to be made between polymeric chains, optimizing the resistance and elasticity of chitosan membranes.85 Further, chitin/chitosan have the ability to chelate with the Ca2+ or Mg2+ present in the cell wall of bacteria, thus destroying the entity of bacterial cell wall, and to react with the anionic phosphate groups of phospholipids found on the bacterial cell membrane by using their NH3+ amino group, thereby leading to changes in the cell membrane permeability and eventual release of the bacteria’s cellular contents.84,86 These functional capabilities make chitin/chitosan-based materials exhibit a bactericidal effect on both Gram-negative and Gram-positive bacteria, giving them a broad medical utility in tissue engineering and biomedical applications.84,86

| Figure 2 Structure of chitin and chitosan. |

Specifically, chitin/chitosan-based materials have demonstrated potential with regard to connective, nerve, adipose, and vascular tissue-engineering applications.87–89 For example, a silk fibroin (SF)/chitin-based scaffold was used to repair a musculofascial defect in the abdominal wall, displaying continuous integration with adjacent native tissue and mechanical strength similar to native tissue.88 Similarly, chitosan/hydroxyapatite-based scaffolds loaded with bFGF for periodontal tissue regeneration promoted vigorous proliferation and migration in periodontal ligamental cells and cementoblasts.87 A more recent study produced nanosized chitosan/hydroxyapatite-based scaffolds via thermally induced phase separation and lyophilization techniques and found that this combination demonstrated greater compressed mechanical properties as compared to the pure chitosan scaffold – a property critical for the success of scaffolds to be used as tissue-engineering scaffolds.90 Further tests will need to be conducted, but it is expected that this scaffold will allow cell attachment and tissue growth in vivo as well. Taken together, these results highlight the potential of chitin/chitosan-based scaffolds providing a cell-favorable microenvironment for connective tissue healing.

Though chitosan has been widely used for bone tissue-engineering applications due to its various favorable properties as mentioned earlier, it has a lower tensile strength and modulus range than those of natural bones.91,92 In an effort to reinforce the mechanical properties of chitosan, Tamburaci et al combined diatomite (diatomaceous earth), a natural silica material, with chitosan to produce a scaffold for bone tissue regeneration; they found that diatomite-reinforced chitosan composite membranes improved the surface area, roughness, swelling properties, and protein adsorption capacities of traditional chitosan membranes, while showing no cytotoxic effect in Saos-2 osteosarcoma cell line with excellent biocompatibility.93 Interestingly, Tamburaci et al also found that diatomite incorporation into chitosan scaffolds increased the proliferation and alkaline phosphatase activity of Saos-2 cells remarkably.93 Overall, diatomite-reinforced chitosan scaffolds showed improved properties while maintaining the high biological activity typical of traditional chitosan scaffolds, illustrating the potential of chitosan for bone tissue-engineering applications.

Moreover, glutaraldehyde-cross-linked collagen-chitosan hydrogels were successfully applied to adipose tissue engineering. A study confirmed the in vitro viability of pre-adipocytes (PAs) on glutaraldehyde-cross-linked collagen–chitosan hydrogel scaffolds. Subsequently, a rat subcutaneous pocket assay was used to evaluate PA-seeded scaffolds in vivo which displayed excellent biocompatibility, formed adipose tissue, and induced vascularization.89 Additionally, chitin/chitosan-based materials have found success as biomaterials used in cartilage repair due to their biocompatibility and structural similarity with GAGs found in cartilage.12,94,95 Recently, Lee’s group synthesized an injectable hydrogel consisting of methacrylated glycol chitosan and HA by photo-cross-linking with a riboflavin photo-initiator under visible light.12 This resulted in the formation of a cross-linked chitosan network in which high-molecular-weight HA was entrapped, forming a semi-interpenetrating network that provided a more chondrogenic-favorable microenvironment.12 Likewise, these photopolymerizable hydrogels exhibit robust capacity as cell carrier vehicles and further emphasize the advantage of chitin/chitosan-based materials for tissue engineering.

Furthermore, chitin/chitosan-based materials have been incorporated successfully into cutaneous wound management. A number of studies have reported the use of chitin/chitosan scaffolds and membranes to treat patients with deep burns.96,97 Recently, novel α-chitin/silver nanoparticles (AgNPs) and β-chitin/AgNP composite scaffolds were tested for wound-healing applications.96,97 These chitin/AgNPs composite scaffolds were found to possess excellent antibacterial activity against Staphylococcus aureus and E. coli, combined with good blood clotting ability.96,97 In addition, β-chitin/AgNP composite scaffolds functioned as promising matrices capable of providing good cell attachment apart from their antibacterial activity, which suggests that these composite scaffolds are ideal for wound-healing applications.97

Finally, chitin/chitosan-based materials have presented excellent potential in drug delivery systems. For example, in one study, when carboxymethyl chitin nanoparticles were cross-linked with FeCl3 and CaCl2, they were shown to be nontoxic to mouse L929 cells while showing significant antibacterial activity against Staphylococcus strains.98 Studies indicating that chitin/chitosan-based materials may be used for controlled drug delivery in managing HIV are more exciting. In one study that focused on anti-transferrin and anti-bradykinin B2 antibody-conjugated chitosan nanoparticles, the investigators found that chitosan nanoparticles presented the potential to effectively penetrate across the blood–brain barrier and thus enhance the drug delivery in the brain to inhibit HIV replication in the neural system.99 Another study showed that using chitosan nanoparticles to encapsulate conventional antiretroviral drugs targeting HIV led to a more efficient control of the viral proliferation in target T cells.100 Greater cell targeting efficiency was achieved, mostly due to the fact that chitosan nanoparticles are mildly immunogenic, making them more visible to the immune system, allowing for more efficient uptake by phagocytes.100 A separate investigation studied the effects of poly(lactic acid) (PLA)/chitosan nanoparticles loaded with lamivudine (a type 1 and type 2 HIV selective inhibitor) in mouse L929 fibroblast cells.101 The in vitro drug-release studies showed that the drug release rate from PLA/chitosan nanoparticles decreased when the pH of the medium changed from alkaline to acidic and further decreased from acidic to neutral, which could be a result of the repulsion between H+ ions and cationic groups present in the polymeric nanoparticles.101 Because it is ideal that the drug encapsulated in the delivery system will be protected in the stomach environment at acidic pH and then provide sustained release in the intestines (neutral pH), these findings suggest that the chitosan-based nanoparticles exhibit excellent potential as a carrier system for HIV-controlled drug delivery.

Besides HIV management, chitin/chitosan-based materials can be used in cancer therapy as drug-delivery vehicles. For example, a pH-responsive magnetic nanocomposite was wrapped in chitosan for targeted and controlled drug delivery, and the yield product was found to be nontoxic and exhibited a high antitumor activity while maintaining its excellent pH sensitivity at pH <6.0.102

In addition to improving the targeting and efficiency of cancer and HIV drug-delivery vehicles, chitin/chitosan-based materials have been utilized in various other delivery systems. In a very recent study, Di et al developed an ultrasound-triggered insulin-delivery system which allows for pulsatile insulin release that can provide both long-term, sustained and fast on-demand responses.103 This system incorporated insulin-loaded PLGA nanocapsules encapsulated within chitosan microgels and, upon ultrasound treatment, the stored insulin can be rapidly released to regulate blood glucose levels.103 The research group found that in a mouse model of type 1 diabetes, a 30-second ultrasound administration could effectively achieve glycemic control for 1 week and concluded that this delivery system may potentially be used to release other therapeutics in a noninvasive and convenient manner.103 Moreover, Liang et al104 and Jing et al105 have shown that chitosan derivatives as a delivery system can also enhance oral tablet absorption of bioactive compounds and potentially allow protein and certain peptide drugs to be orally administrable. In addition, hydroxyethyl chitosan – a derivative of chitosan – has shown great potential as a drug-delivery material for the treatment of glaucoma and other ocular diseases due to its great water-solubility and excellent biocompatibility.106 Further investigations must be carried out to assess any side-effect or instability of chitosan-based materials; however, there seems to be substantial potential for chitosan-derived drug-controlled-release systems.

Chitin/chitosan-based materials are widely studied for several different tissue-engineering applications, regenerative medicine, wound healing, and drug delivery for good reason. They have excellent biodegradability and biocompatibility and has been known to have antiulcer, anti-acid, hypocholesterolemic action, wound-healing, antitumor, and hemostatic properties.107–110 Although chitin/chitosan-based materials tend to lack mechanical properties, they possess functional reactive side groups that can be cross-linked to make bridges between polymeric chains, optimizing the resistance and elasticity of these materials.85 Due to their unique combination of physical and chemical properties, chitin/chitosan can be molded relatively easily into porous scaffolds, and their cationic nature allows them to form polyelectrolyte complexes with many types of anionic GAGs, making them capable of modulating the activity of a variety of growth factors and cytokines for tissue-engineering purposes.85 An important property of chitin/chitosan is its mucoadhesive nature and its ability to open epithelial tight junctions, making them well-suited for drug delivery across nasal, intestinal, ocular, buccal, and pulmonary systems.85 However, some challenges do exist. Chitosan is insoluble in most organic solvents, making delivery of hydrophobic drugs difficult; moreover, various methodologies to adapt the solubilization of chitosan, such as alkylation, acetylation, and carboxymethylation, all come with certain drawbacks and limitations.111

Overall, chitin/chitosan is a polymer that will have very important applications in both the industrial and biomedical fields of the future. Its unique chemical properties have recently allowed it to be studied as part of a biological functionalization of microelectromechanical systems, which will enable it to perform functions such as biorecognition, enzymatic catalysis, and controlled drug release, all of which is critical to the advancement of drug-delivery and scaffold technology.85

Starch

Starch is the primary energy reserve polysaccharide in plants, and it is present in the form of granules composed of amylose and amylopectin.112 Amylose is a linear polymer composed of glucose monomers linked through α-D-(1–4) glycosidic linkages, whereas amylopectin molecules are huge, branched polymers of glucose known to be one of the highest molecular-weight natural polymers.113 Different plants have slightly different granule sizes, amylose/amylopectin ratio, mineral contents, and amount of phosphorous and phospholipid contents that lead to varying starch properties.112 The specific characterization of starch is particularly important due to different swelling, solubility, gelatinization, mechanical behavior, enzymatic digestibility, rheological characteristics, and surface characteristics, which affect the way it needs to be processed to convert it to a more usable form such as hydrogels, pastes, and nanoparticles.114 Generally, the native starch isolated from different plants tends to have limited shear resistance, thermal resistance, thermal decomposition, and a high tendency toward retrogradation.112 These limitations have been overcome by combining starch with more stable, synthetic, thermoplastic polymers, or utilizing physical treatment of starch, such as heat or moisture, or utilizing chemical modifications, introducing certain functional groups to remarkably alter its physicochemical properties, making starch vastly more useful in tissue engineering, drug delivery, and delivery of biologically active compounds.112

Among its tissue-engineering applications, starch is most famous for its usefulness in generating scaffolds for bone regeneration due to its bone-bonding behavior when reinforced with hydroxyapatite, good mechanical properties, non-cytotoxic and biocompatible nature, excellent substrate for cell adhesion, and thermoplastic behavior when combined with thermoplastic polymers.115 Lately, further improvements have been made to these starch-based scaffolds. In one recent study, Mahdieh et al synthesized a nanocomposite biomaterial consisting of a blend of thermoplastic starch and ethylene vinyl alcohol as the polymer matrix, and incorporated nano-structured forsterite and vitamin E as the ceramic reinforcing phase and thermal stabilizer, respectively.116 What they found was that nanofosterite, a newly developed bioceramic, resulted in improved biological and mechanical properties, thereby reducing the degradation rate of the scaffold whereas stimulating bone cell proliferation in comparison to the traditional starch–ethylene vinyl alcohol matrix.116

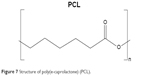

In particular, starch and PCL blends (SPCL) have garnered much attention from many research groups for application as a tissue-engineering construct.117 PCL improves the processability of starch, reduces its high stiffness, and can overcome the high moisture sensitivity of starch, which is one of the greatest weakness of starch as a biomaterial.118 On the other hand, starch improves the biodegradability of PCL and, as the cheapest biomaterial on the planet, starch can substantially lower the high cost of the final product.119 Through the appropriate blending of starch and PCL, SPCL can overcome limitations of both PCL and starch, whereas additionally allowing for control over mechanical and degradative properties by adjusting the component ratio – a significant advantage that allows it to conform to the numerous differing tissue-regenerative rates.120 SPCL is particularly effective in bone engineering because one of the greatest biological specifications of SPCL composites is their ability to enhance and stimulate osteoblast cell proliferation.117 In fact, several different research groups have recently experimented with SPCL for this purpose.117 Carvalho et al studied the bone regeneration potential of undifferentiated human adipose-derived stromal/stem cells loaded in SPCL scaffolds for the regeneration of critical-sized mice calvarial defect.121 They found that SPCL was a suitable scaffold for bone tissue engineering, allowing for new tissue formation in the calvarial defect to be approximately 20% of the defect size after 4 weeks and 43% at 8 weeks.121 Link et al did a similar study of critical-sized cranial defects in male Fisher rats and found that the SPCL fiber mesh proved to be an effective osteoconductive material for bone regeneration.122 Requicha et al studied the in vivo behavior of a novel, double-layered SPCL scaffold functionalized with silanol groups (SPCL-Si) in a mandibular rodent model and compared the results to a commercial collagen membrane.123 They found that SPCL-Si scaffolds induced significantly higher new bone formation when compared to the commercial collagen membrane.123

Starch has been proposed as a possible drug-delivery system.124 In its hydrogel form, it can efficiently entrap drugs in interstitial spaces, thus protecting them from undesirable conditions in the human body.125 In addition, starch hydrogels are resistant to gastric juices, allowing for potential oral drug-delivery systems, and they can be modified to be degraded in very specific portions of the gastrointestinal tract, thus allowing for site-specific delivery.126 Moreover, physical modification of starch by retrogradation leads to the development of high levels of type three resistant starch – a very thermally stable, low solubility form of starch that makes it suitable for colon-specific delivery systems.124 However, in practice, studies on starch as a possible drug-delivery system have been very limited. Most of the research on starch as part of a drug-delivery system is theoretical, and scientists are still exploring the possible consequences of physical modification of starch on the mechanical and structural properties of hydrogels. To date, there is no conclusive data on this subject.

As the cheapest, most bioavailable, natural polymer, starch is an interesting renewable resource that may have many different biomedical applications.119 Starch is entirely biodegradable, noncytotoxic, biocompatible, and exhibits a high Young’s modulus with low levels of elongation at break.117 It is relatively easy to modify chemically, and it has the ability to replace some more expensive, synthetic polymers in the fabrication of composite biopolymers.127 When starch is combined with PCL, SPCL exhibits additional properties, such as better processability, increased mechanical properties, controllable degradability, and enhanced osteoblastic cell proliferation whereas still being relatively cheap to produce.117 As the study by Requicha et al showed recently, functionalized SPCL-Si polymers induced much higher rates of bone formation as compared to the traditional (30:70) SPCL blend, further showing the potential of starch-based biopolymers as scaffolds.123 However, research outside of bone tissue engineering has largely been limited, and the potential for drug delivery, while theoretically studied, has been relatively unexplored as compared to many other natural polymers. Further research needs to be undertaken to exploit the abundance of starch for use in more than just bone tissue engineering.

Alginate

Alginate is a polysaccharide derived from the cell wall of brown seaweed and extracellularly in some bacteria. It is an anionic polymer that is biocompatible, nontoxic, and non-inflammatory – as long as it undergoes multi-purification steps – but it is primarily known for its mild gelation conditions, low cost, and relatively simple modifications in making alginate derivatives with new properties.128 In particular, alginate hydrogels have been prepared by various chemical or physical cross-linking methods for diverse applications in wound healing, delivery of bioactive agents, and tissue engineering.129 The primary drawbacks of alginate are its generalized lack of strong mechanical properties, poor cell adhesion, and its lack of degradability in mammals.128 However, by combining alginate with other biomaterials such as agarose and chitosan, and by partially oxidizing alginate with molecules like sodium periodate, scientists have managed to enhance its mechanical properties and degradability, conferring significant promise on alginate-based biomaterials.129

Lately, there has been a surge of research in the use of alginate for regeneration and engineering of various tissues and organs in the body. One study attempted to create a tissue-engineered skin substitute by developing a fish collagen/alginate (FCA) sponge scaffold that was then functionalized by combining different molecular-weight chitooligosaccharides (COS) with the help of a cross-linking agent.130 What they found was that the excellent biological and functional properties of collagen, along with the controllable porosity of sodium alginate, helped create a matrix for the cellular growth in skin tissue regeneration.130 The addition of COS to FCA, creating FCA/COS1, resulted in a scaffold with improved cell adhesion and proliferation, ECM compatibility, improved porosity and water uptake, and overall superior physical, mechanical, and biologic properties that could potentially be a candidate for skin tissue-engineering application.130 Another study blended alginate with poly(ethylene oxide) (PEO), and the resulting product was then modified by acidification of carboxylate groups via trifluoroacetic acid (TFA) to produce poly(alginic acid).131 Whereas electrospun scaffolds of sodium alginate are often limited in use for tissue engineering due to high solubility and uncontrollable degradation dynamics, the poly(alginic acid) exhibited an enhanced stability in the aqueous environment and controllable degradability by changing the duration of the TFA–alginate reaction, making it attractive in the production of biomedical devices for tissue engineering.131

Alginate – due to its favorable gelation conditions, biocompatibility, and relatively simple modifications – has also been studied for its use in bone regeneration and myocardial tissue regeneration.132 One study showed that utilizing alginate as a dispersing agent in hydroxyapatite/chitosan composites helps to create more uniform pore structures than using just hydroxyapatite/chitosan composites.133 The increased pore morphology contributed to an increase in the elastic modulus and compressive strength of the scaffold, thus substantially improving osteoblastic differentiation for bone regeneration.133 In a separate study, a novel nano-biocomposite scaffold combining chitosan, gelatin, alginate, and hydroxyapatite was shown to have mechanical and biological properties mimicking natural bone.134 They found that they could take advantage of alginate’s anionic nature, coupled with its excellent cross-linking abilities – especially in the presence of multivalent cations – to produce an incredibly stable nanocomposite scaffold with a prolonged degradation time necessary for the formation of neotissue and the ECM.134 When it comes to tissue engineering, treatment of cardiac tissue is of notable interest, especially in the case of myocardial infarctions (MIs) where large portions of functional tissue are often lost. In a study of a rat model of acute MI, Kim et al attempted an immediate post-MI local injection of alginate–chitosan hydrogel into the peri-infarct zone and assessed the results 8 weeks later.135 What they found was that this treatment promoted greater angiogenesis, increased recruitment of endogenous repair at the infarct zone via recruitment of cardiac stem cells, prevented cell apoptosis, induced cardiomyocyte cell re-entry, and, most importantly, prevented deterioration of cardiac function.135 The hydrogel-injected animals demonstrated marked improvements after extensive MI and, given the simplicity of manufacturing and the entirely natural makeup of such a hydrogel, alginate-based biomaterials for myocardial regeneration is likely to play a huge role in cardiovascular repair in the future.135 Furthermore, sodium alginate has one of the largest applications in the field of wound healing, due in part to not only its excellent bioresorbable and biocompatible nature, but also because of its ease of gelation and its physical cross-linking abilities, which is often favored over chemical cross-linking due to the ease with which they can be performed.132,136 One study formulated freeze-dried wafers combining a 75/25 sodium alginate-to-gelatin ratio and loaded it with silver sulfadiazine (a metal antimicrobial) for application on infected wounds.137 Sodium alginate gel was used as the main biomaterial primarily because it allows exchange between ions in the wound exudate and the dressing, thereby creating a moist environment that promotes healing.137 The gelatin is mixed in to prevent hydrated alginate from losing cation-crosslinkers over time, allowing the wound dressing to release the silver sulfadiazine over a 7-hour period, and severely reducing the bacterial bioburden compared to traditional wound dressings.137 Another study found that combining the use of alginate and deoxyribonucleic acid (DNA)-based gels resulted in a sustained release of bioactive factors such as outgrowth endothelial cells, as well as neuropeptides and growth factors for treatment of diabetic foot ulcers, leading to a substantially better healing outcome than the delivery of these bioactive factors alone.138 Moreover, in yet a different study, scientists found that integrating hyaluronic acid in an ionically cross-linked alginate matrix hydrogel promoted significant gap closure on dermal wound injuries compared to using either biomaterial alone.139 The addition of hyaluronic acid significantly improved the mechanical properties necessary for a wound dressing whereas only very minimally affecting alginate gelation time, providing an effective and easy way to improve excisional wound injuries in a clinical setting. That is not to say that alginate-derived wound dressings have been entirely successful.139 In one study, a 500-block randomized prospective study was done to test the effects of a silver-eluting alginate dressing to reduce lower-extremity vascular surgery wound complications compared to a standard dry surgical dressing. They found no significant difference in using this silver alginate dressing in reducing postoperative wound complications.140 However, it is clear from these novel studies and others that alginate-based wound dressings will continue to play a significant role in the future as the relative ease of modifiability of alginate properties will allow researchers to explore a limitless number of possibilities and solutions to promote better healing.

Alginate is a widely utilized biomaterial, especially in regenerative medicine and in tissue engineering, due to its biocompatibility, mild and physical gelation process, chemical and physical cross-linking abilities, non-thrombogenic nature, and the resemblance of its hydrogel matrix texture to that of the ECM.132 Moreover, alginate happens to be easily modified into any form, such as microspheres, sponges, foams, elastomers, fibers, and hydrogels, thereby broadening the scope of application of alginate-based biomaterials, and it can be combined with other natural biomaterials to create and enhance new and existing properties.141 Due to the abundance of algae in water bodies, alginate is one of the most prevalent natural biomaterials in the world, making it relatively a low-cost and feasible biomaterial to use.142 However, better control of polymer properties and development of its tissue-interactive forms are necessary for breakthroughs in many tissue-engineering applications.132 The introduction of cell-interactive features to alginate biomaterials will become crucial in the future to properly produce replacement tissues and even organs.132 The type of adhesion ligands and spatial organizations in the hydrogel of alginates are key for proper functioning of regenerated tissues, and although arginylglycylaspartic acid (RGD) peptides have been used mostly to date as a cell adhesion ligand, multiple ligands in combination – along with solubility factors – will be necessary to further our application of alginate-based biomaterials for regenerative purposes.129 For wound-healing applications, alginate-based gels will need to play a more active role, incorporating one or more bioactive agents to facilitate wound healing as compared to the rather passive process they play in current clinical applications.129 The future of alginate-based wound dressings hinges upon establishing more control over the delivery of one or more drugs, as well as their duration and sequence of release while considering external environmental changes.129 Furthering our understanding of the fundamentals of alginate properties will help researchers take advantage of the remarkable properties and bioavailability of alginate and utilize genetic engineering techniques to control the bacterial synthesis of alginate with new and improved properties, thus revolutionizing the use of this material.129

Silk

Silk fibers are natural biopolymers derived primarily from the silkworm Bombyx mori.143 The silk fiber consists of two parallel SF proteins, held together by a layer of silk sericin protein glue on the surface.144 Until recently, silk sericin has been deemed to be immunologically incompatible with the human body and has, therefore, been largely neglected as a biopolymer.145 However, SF has been used as a biomedical suture material for centuries.143 It is a semi-crystalline structure that has an incredible combination of mechanical properties, possessing very high tensile strength, coupled with excellent elasticity and flexibility.143 In fact, its strength-to-density ratio is up to ten times higher than that of steel.146 SF’s unique mechanical properties, tunable biodegradability, diverse side-chain chemistries, and the fact that genetic engineering techniques can be used to tailor the protein, allows it to have a variety of novel properties, functions, and applications in the biomedical field.143 Furthermore, SF derived from other species in the order Lepidoptera often have other unique properties, increasing their potential for biomedical use.145 In addition, some spiders, such as Antheraea mylitta, have been found to produce silks that possess better cell adhesion and a more highly ordered crystalline structure, leading to increased mechanical strength and lower solubility in acidic solvents.145 Additionally, because SF is easily processed into gels, films, nanoparticles, membranes, nanofibers, scaffolds, and foam-like forms, they can be adapted to mimic a tremendous diversity of tissues in the human body.143 As a result, SF has lately been studied for use in several different applications, including almost all fields of tissue engineering, wound repair, drug delivery, and even as a possible bio-ink for 3D bioprinting.147

SF’s unique combination of elasticity, strength, and potential self-healing modifications (via cross-linking), along with its biocompatibility, tunable biodegradation, anti-bacterial, and other mechanical properties, makes it an attractive material to include as a part of a composite scaffold for tissue engineering.148 Several different studies in the past few years have explored SF-based biomaterials for tissue engineering. In one study, Shao et al designed a nanostructured composite scaffold with the core consisting of hydroxyapatite and SF.149 The composite fibers were fabricated by electrospinning – a technique used to generate nanoscale polymeric fibers using electrical energy – to create a nanofiber composite scaffold, and then subsequently compared to nanofibers of pure SF.149 They found that the composite scaffold demonstrated a 90-fold and 2-fold increase in initial modulus and breaking stress, respectively.149 Osteoblast-like cells were cultivated on the composite, and Shao et al found that the composite scaffold demonstrated increased biocompatibility, better cell adhesion, and proliferation as well as functionally promoted alkaline phosphatase and biomineralization.149 The group concluded that the nanostructured composite scaffold consisting of a hydroxyapatite and SF core has excellent biomimetic and mechanical properties and has potential as a biocompatible scaffold for bone tissue engineering.149 In another study, Tian et al utilized the same coaxial electrospinning technique to fabricate a nanofiber scaffold (p-PS/N) consisting of nerve growth factor, SF, and PLA.150 After 11 days, the PC12 cells (a model for neuronal differentiation) that were cultured on these scaffolds showed elongated neurites with lengths up to 95 μm, leading the research group to conclude that p-PS/N scaffolds were able to support the attachment and differentiation of PC12 cells for nerve tissue engineering.150 Another research group independently developed a 3D porous SF scaffold derived from the non-mulberry muga silkworm of Antheraea assamensis to examine its ability to support cartilage tissue engineering.151 They found that the SF scaffold could generate enhanced sulfated glycosaminoglycans and type II collagen, and demonstrated in vivo biocompatibility after 8 weeks of implantation in a subcutaneous model of rat, suggesting that these non-mulberry SF scaffold may be suitable for chondrocyte-based cartilage repair.151 Moreover, in a separate study, that same research group developed a 3D-blended scaffold consisting of SF and human hair-derived keratin to investigate their ability to promote enhanced fibroblast cell adhesion and proliferation.152 They found that the scaffold demonstrated high porosity and interconnected pores, with excellent thermal, degradation, and mechanical properties.152 In addition, they found increased expression of collagen type I in cultured cells, demonstrating functional fibroblast proliferation, and the research group concluded that blended biomaterials, specifically SF and human hair keratin-blended scaffolds, may have a promising future as a dermal substitute for skin tissue engineering.152 In an attempt to engender enthesis (functional repair of tendons and ligaments), another research group, Tellado et al, engineered a complex scaffold consisting of biphasic SF scaffolds with integrated anisotropic and isotropic pore alignment, similar to what is found in native tendons/ligaments and bone/cartilage, respectively.153 The scaffolds were functionalized with heparin, and human primary adipose-derived mesenchymal stem cells were cultured on the scaffold and assessed for their ability to deliver transforming growth factor β2 (TGF-β2) and growth/differentiation factor 5 (GDF5).153 This research group found that heparin functionalization increased the amount of TGF-β2 and GDF5 attached to the scaffold, leading to enhanced expression of cartilage and collagen II protein contents and enthesis, demonstrating that growth factor-loaded biphasic SF scaffolds may be useful in tendon/ligament repair.153

In addition to its numerous tissue-engineering applications, SF has recently been explored for its use as a biomaterial for skin repair due to its excellent hemostatic properties, low inflammatory potential, and permeability to oxygen and water vapor.154 Preliminary studies have even shown that SF film and sponge-based dressings promote wound healing and enhance skin regeneration compared to traditional hydrocolloids.154,155 Currently to date, there are only three SF-based medical products approved for clinical use in the world: SeriScaffold (Allergan Medical, Inc.) from the US FDA, TymPaSil (CG Bio Inc.) from the Ministry of Food and Drug Safety of South Korea and Sidaiyi (Suzhou Soho Biomaterial Science and Technology Co., Ltd) from the China Food and Drug Administration.156 Of these three, only Sidaiyi is indicated for skin wound healing, but none of these three products are widely utilized in clinical practice.156 A very recent clinical study done in 2017 by Zhang et al focused on developing a translational SF film for clinical application.156 They conducted a single-blind, parallel, controlled clinical trial on 71 patients for treating donor-site wounds.156 Compared to the positive control Sidaiyi, the SF film demonstrated substantially faster wound healing, taking approximately 9.86 days on average to complete wound healing, compared to 11.35 days for Sidaiyi.156 Further, 100% of the patients treated with the SF film healed by Day 14, whereas 88.6% of patients treated with Sidaiyi healed by Day 19.156 Only one inflammatory reaction case and zero adverse reaction cases was noticed in the SF film group, whereas three inflammatory reaction cases and four adverse cases were recorded in the Sidaiyi group.156 The SF film group had cleaner wounds compared to the exudate-prone wounds of the Sidaiyi group, due to its better fluid handling capacity and gas permeability.156 This translational study, taken together with its previously successful studies on rabbit and porcine wound models, demonstrates that this newly developed SF film may indeed be safer and more effective than the Sidaiyi material currently available for clinical use in China for the treatment of skin repair and regeneration.156 To date, many other studies have recently shown positive in vitro results with electrospun nanofiber SF dressings, or composite SF dressings, as a way to enhance the bulk properties of SF.157–161 Based on all these studies, it is clear that SF potentially has a very good outlook for the future.156

Besides the properties already mentioned, SF has many other unique and standout properties that make it excellent for use as a drug carrier.148 It can allow for loading of even the most sensitive of drugs, such as proteins and nucleic acids, due to its mild, all-aqueous processing conditions.148 Moreover, SF has a diverse range of amino acids with several functional groups that can simplify the attachment of different types of biomolecules or antibodies, giving it a wide degree of functionalization.162 Finally, SF naturally has an intrinsic respond to pH changes, making it easy to control drug-release kinetics, and the mechanism of elimination from the body can easily be done by degradation via proteolytic enzymes in the body, leaving no likely side effects.163 Recently, most research groups have been investigating the mechanistic component of incorporating SF nanoparticulate for protein delivery, small-molecules delivery, and even anticancer delivery.164–166 These studies have been investigating properties of SF such as electrostatic interactions for loading efficiency, different drug-delivery mediums for controlling drug-release kinetics, and encapsulation efficiency, as well as compatibility, degradability, and drug retention.163 However, SF’s potential role in drug delivery has yet to be established due to the relative infancy of SF nanoparticulation, and further intensive examinations regarding SF properties and how to best exploit and improve those properties for drug delivery remains to be seen.163

Tissue-engineering techniques at present, while having improved vastly from years before, still fail to capture the complexity of the 3D anatomy and functionality of human tissues and, as a result, very few engineered constructs reach human clinical trials.147 3D bioprinting offers an untapped potential to capture the complexity of human tissues, and it has been touted as the future of tissue-regeneration strategies.167 One of the most crucial aspects of 3D printing is bio-ink design, which not only provides the 3D architecture but also acts as the first point of contact for cells to synthesize regulatory proteins and cytokines appropriate for the tissue it is mimicking.168 Silk has become one of the most popular choices for bio-ink preparations. The ability to physically cross-link its protein polymer chains via inter- and intramolecular β-sheet semi-crystalline structure formation allows it to be stabilized after printing without the need for any chemical or photochemical reactions or additives.169 In addition, silk is a very strong and robust material as previously mentioned, and its inherent spinnability, cytocompatibility, and controllable degradability make silk a very strong candidate for future bio-ink preparations.147 Of course, studies are still in its infancy stages and, so far, reported literature on silk 3D bioprinting has demonstrated cell viability after printing to be anywhere from 45% to 98%.170 However, of the limited available hydrogel bio-inks currently tested, optimized blends of B. Mori silk–gelatin bio-inks has shown the most potential for 3D bioprinting of functional tissue equivalents.147 Significant scientific and regulatory challenges still remain before 3D bioprinting technology can hit commercialization levels, and more experimental studies need to be done on optimizing silk as a potential bio-ink.147

SF-based biomaterials have immense potential as one of the preeminent natural biopolymers studied today. Its ease of structural modification, controllable degradability, high tensile strength, elasticity and flexibility, potential to introduce physical cross-links, hemostatic and self-healing attributes, and its ability to be processed into numerous different forms, such as sponges, films, and hydrogels, make SF a polymer with various biomedical applications.143 However, unlike starch or more bioavailable polymers, silk is produced by only a select number of species, and only in B. Mori are they available in appreciable amounts.143 Although spider silk has been shown to display impressive toughness, stiffness, strength, and extensibility, it is impractical to obtain any large quantities of silk from any spider.145 One study has pointed to the transgenic expression of spider silk in plants (eg, tobacco and potato) or utilizing mammalian epithelial cells as a way to garner a more substantive production of silk, but so far, no solutions are in place.171,172 Besides sustainability, the key to developing new silk-incorporated biomaterials and to advance our current technology in tissue engineering is to work on surface modifications or compositing with other synthetic polymers and to figure out how to control crystallization in SF when it is thermally treated or mechanically stretched.145 With novel cross-linking methods, SF-based materials can be designed to self-heal, which will result in new applications for tissue engineering and wound healing.145 Silk sericin – the neglected protein in silk fibers – also needs to be studied in more depth. While it has long been deemed biologically incompatible with the human body, new studies show that silk sericin is only immunogenic when associated in conjunction with SF.145 When used by itself, or combined with other biopolymers, sericin has been shown to have attractive bioactive properties, with its antioxidant character, moisturizing ability, and mitogenic effect on mammalian cells.173 Its promotion of keratinocytes and fibroblasts have led to the development of sericin-based biomaterials for skin tissue repair, and its ability to be cross-linked with genipin can allow for it to be used in bone, dermal, and neural tissue engineering.174 Furthermore, sericin may be utilized for drug delivery because it can help facilitate the fabrication of nano- and microparticles, hydrogels, and conjugated molecules, through its chemical reactivity and pH-responsiveness, thus improving the bioactivity of drugs.173 Currently, methods of purifying silk sericin protein have been mostly met with unpredictable results in size, composition, and biological activity, but future technological advancements and recovery methods may lead silk sericin to be an important biomaterial in the field of tissue engineering and drug delivery.144

Polyhydroxyalkanoates (PHA)

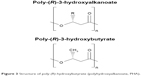

PHA is a class of natural, biodegradable polyesters synthesized by microorganisms as intracellular carbon- and energy-storage compounds in uneven growth conditions.175 They have exceptional biodegradability and biocompatibility, and produce nontoxic degradation products, making them excellent for use in biomedical applications such as drug delivery, tissue engineering, and substitute for implantable devices,176 including sutures, repair patches slings, orthopedic pins, scaffold, stents, and adhesion barriers.177 However, unmodified PHAs – despite their exceptional abilities mentioned above – have some important limitations, such as the presence of large crystals causing poor mechanical properties,178 poor thermal stability, high hydrophobicity, and slow degradation rate, rendering them unfavorable to be used for many biomedical applications.179 The intrinsic hydrophobicity of PHAs impedes their utilization in biomedical applications,177 as many biomedical appliances require better hydrophilicity.179 Moreover, PHAs are lacking in chemical functionalities, and the polyesters are frequently incompatible when combined with drugs.177 Although biodegradable, PHAs are extremely stable when unmodified, thus diminishing their therapeutic functions in other areas.177 Meanwhile, uncommon PHAs possessing functional side groups including hydroxyl- and/or carboxyl groups, methylated-branches, and other hydrophilic derivatives have been produced by a few organisms to broaden the applicability of PHAs.180 Therefore, it is crucial that PHAs need to be modified to fix these properties while maintaining their exceptional characteristics to make them capable for use in biomedical applications.

| Figure 3 Structure of poly-(R)-hydroxybutyrate (polyhydroxyalkanoate, PHA). |