Back to Journals » Risk Management and Healthcare Policy » Volume 14

Temporary Hearing Loss and Associated Factors Among Ayka Addis Textile Factory Workers in Oromia Region, Ethiopia: A Cross-Sectional Study

Authors Angaw Y , Kumie A, Tefera Y , Wakuma S, Nega A, Degefa HD , Mehari M , Alemseged EA , Hailay A , Gebremeskel F, Mamo H , Belay H , Berwo Mengesha M, Teame H

Received 27 June 2020

Accepted for publication 30 October 2020

Published 18 February 2021 Volume 2021:14 Pages 719—728

DOI https://doi.org/10.2147/RMHP.S269609

Checked for plagiarism Yes

Review by Single anonymous peer review

Peer reviewer comments 3

Editor who approved publication: Professor Marco Carotenuto

Yonas Angaw,1 Abera Kumie,2 Yifokire Tefera,2 Samson Wakuma,2 Ansha Nega,2 Hagos Degefa Hidru,1 Medhin Mehari,1 Embay Amare Alemseged,1 Abadi Hailay,1 Fre Gebremeskel,1 Haftom Mamo,3 Hailu Belay,3 Meresa Berwo Mengesha,4 Hirut Teame1

1College of Medicine and Health Science, Department of Public Health, Adigrat University, Adigrat, Ethiopia; 2College of Health Science, Department of Public Health, Addis Ababa University, Addis Ababa, Ethiopia; 3College of Medicine and Health Science, Department of Psychiatry, Adigrat University, Adigrat, Ethiopia; 4College of Medicine and Health Science, Department of Midwifery, Adigrat University, Adigrat, Ethiopia

Correspondence: Yonas Angaw Email [email protected]

Introduction: The development of modern automated machines in industries has considerably decreased the physical burden of workers in addition to increasing the productivity of the industries resulting in noise pollution. Noise exposure above the limit value of 90 dB (A) is known to cause temporary hearing loss among exposed workers.

Materials and Methods: Institutional-based cross-sectional study design was employed for a total of 406 study participants using a simple random sampling technique from January 15 to April 30, 2019. The data collection methods were observational checklist and a self-administered questionnaire. The collected data were entered into EpiData software version 4.2 and exported to SPSS software version 21 for analysis. Bivariate and multivariable logistic analyses wwere used to identify the associated factors. Statistical significance was declared using a 95% confidence interval and a p-value of less than 0.05.

Results: A total of 388 study participants were included in the study with a response rate of 95.6%, of which 254 (65.5%) were females. The overall temporary hearing loss among the textile factory workers was found to be 49% with COR=1.53; 95% CI (1.15– 2.03). The workers from the spinning department were 2.38 times more likely to develop temporary hearing loss after exiting from work than workers from the dyeing department (95% CI= (1.16– 4.90). Similarly, workers from the knitting department were 3.67 times more likely to develop temporary hearing loss after exiting from work than workers from the dyeing department (95% CI=1.42– 9.47).

Conclusion: The present study demonstrated that the workforce in the spinning and knitting departments of the textile factory had a high prevalence of temporary hearing loss than the workers in dyeing and garment working sections. Therefore, the textile factory should provide hearing protection devices to the workers.

Keywords: noise exposure, temporary hearing loss, Ayka Addis

Background

The development of modern automated machines in industries has considerably decreased the physical burden of workers in addition to increasing the productivity of the industries. However, one of the most undesirable and unavoidable by-products of these operations and machines is noise-pollution.1 Noise is an unwanted sound that exposure to a high level can lead to temporary hearing loss among workers.2

Noise exposure is defined as “the environmental disturbance caused by noise or noise resulting in feeling unrested for living in the vicinity and is one of the most widespread occupational and environmental hazards in the world.3 Average noise exposures >90 Decibel A (dBA) have been linked to a variety of adverse auditory effects including noise-induced temporary hearing loss, which may interfere with workers’ ability to hear warning signals or monitor workplace equipment.4

Noise can also exceed the attenuation rating of the Hearing Protective Devices (HPDs), can be transferred via air leaks, or can be transmitted via bone conduction through mechanical stimulation of the skull.5 Health effects of noise on individuals depending on the level of noise, individual susceptibility, duration of exposure, availability of HPDs, and awareness on the use of these HPDs. Exposure duration of 40 hours per week of equivalent noise level <90 dB (A) is considered to be safe and noise level above this limit is bound to cause noise-induced hearing impairment such as temporary hearing loss.6 In Ethiopia also exposure to noise with respected time or hours is sated with the Ethiopia occupational safety and health directives as to the following: 90dBA for 8hrs, 92dBA for 6hrs, 95dBA for 4hrs, 97dB A for 3hrs, 100dB A for 2hrs, 102dB A for 1 and ½ hrs., 105dBA for 1hr, 110dBA for ½ an hr and 115 dB A for ¼ hr.

Temporary hearing loss is when the hearing level can be produced by brief exposure to high-level sound and recovered after resting time. It is also a threshold shift that recovers to pre-exposure or baseline levels in the hours, days, or weeks following exposure to high noise levels. It is also related to ringing trouble of ears and day to day interference to normal conversations of the exposed workers.7 However, noise-induced temporary hearing loss produced by 10 years of daily exposure is approximately equal to the temporary threshold shift produced by the same noise level after an 8-hour exposure. Development of therapeutics that can reduce or prevent Noise-Induced Hearing Loss (NIHL) is a goal for many research teams, and temporary hearing loss study designs have been the primary model to date for evaluating proposed otoprotective agents in humans.5

Ethiopia is one of the developing countries which introduces different industrial settings and offers one of the largest domestic markets in Africa in terms of textile factory products, given its population size and rapid economic growth. Although dangerous noise levels have been previously measured in Ethiopian factories, only one study has documented specifically about noise-induced hearing loss and workers’ awareness of the utilization of hearing protective devices.

The rationale for temporary hearing loss assessment is largely based on the assumption that demonstrating reduction of temporary hearing loss provides proof of concept for potential protection against permanent hearing loss; that is, it has some predictive value. Most agents shown to reduce temporary hearing loss have also been shown to reduce permanent hearing loss, although some other agents that reduce temporary hearing loss have had less consistent effects in temporary hearing models.8 Thus, this study was designed to assess temporary hearing loss and associated factors among the Ayka Addis textile factory workers.

Materials and Methods

Study Area and Period

The study was conducted in Ayka Addis textile factory (12 km from the center of Addis Ababa, capital of the country), the Ethiopian subsidiary of the Turkish textile which was inaugurated in 2010 for US$140 million at Sebeta (Alemgena). The textile factory includes 4157 production section workers. The textile factory has four production departments/sections such as spinning, knitting, dyeing, and garment. The study was conducted from January 15 to April 30, 2019.

Study Design

The institutional-based cross-sectional study design was employed.

Source Population

All employees working and involved in different production activities at Ayka Addis textile factory was used as a source population.

Study Population

Employees who were working in Ayka Addis textile factory and satisfied the inclusion criteria were study subjects.

Eligibility Criteria’s

Inclusion Criteria

Workers with at least one year of service in different production sections of the textile factory were included irrespective of sex and age.

Exclusion Criteria

Workers who had any type of noise-induced hearing loss (deafness), permanent hearing problem and seriously ill (head injury, other severe illnesses)

Sample Size Determination and Sampling Technique

Single population proportion formula was used to determine the sample size, assuming the prevalence of temporary hearing loss 40%,9 95% confidence interval, 5% margin of error with a 10% non-response rate. 406 subjects were taken as a final sample size for this study. A list of individuals from the attendance in the study factory was used as a sampling frame and the sample was distributed based on probability proportion to size (PPS) allocation method to each production section based on the total number of workers per each production department. Then, the respondents were selected using a simple random sampling technique (Figure 1).

|

Figure 1 Schematic presentation of sampling techniques for different work sections in the textile factory, 2019. |

Data Collection Procedures

Self-Administered Questionnaire

A standard questionnaire was developed from the literature of a similar study to assess noise exposure and temporary hearing loss in the textile factory. Since educational level (grade 8–10) is a criterion for hiring workers in the textile factory, a self-administered questionnaire translated to local language (Affan Oromifa) was used to assess workers’ reflection on temporary hearing loss. With close monitoring, the questionnaire was distributed to the selected workers within 2 up to 5 minutes after they accomplish their job or end of noise exposure to identify the real temporary hearing loss that can be caused by noise exposure in the textile factory.

Observational Checklist

An observational checklist was used to assess the institutions’ setup regarding noise control measures such as engineering control and the availability of hearing protective devices. The training status of workers and practices related to occupational health and safety regarding noise hazards was also assessed using the prepared checklist.

Aerial Noise Exposure Level Measurement

An aerial noise survey was performed to assess the general noise exposure level of workers in each working department of the textile factory. Bruel & Kjaer 4448 Personal Dsimeter (Denmark brand) (Figure 2) was used to measure the noise levels in the departments. During the aerial preliminary survey, every 2-meter square, there was a recording of noise level for 5 minutes, and the equipment was held 1.5 m above the floor in every production section of the textile factory. The measurement was performed for 8 hours in each department to identify the exact working time noise exposure of workers in the textile factory. And then the data from the personal dosimeter was transformed into a personal computer using Protector Type 7825 software. Even though Sound Level Measurement (SLM) was recommended to be used for aerial noise level measurement, a personal dosimeter (Bruel & Kjaer 4448) was used to measure aerial noise level in the absence of Sound Level Meter (SLM).

|

Figure 2 Personal dosimeter type 4448 (Denmark brand) used for aerial noise level measurement. |

Data Processing and Analysis

Data were collected by trained environmental health professionals, using a structured pre-tested questionnaire and observational checklist reviewed from related articles. Data were coded, cleaned, checked, and corrected for errors and entered into EpiData version 4.2 and then exported to SPSS version 21 for analysis.

Bivariate logistic regression analysis was done for each variable and variables with their p-value < 0.2 were taken to the Multivariable analysis. The odds ratio was computed to show the strength of the association between the dependent variable and the explanatory variables. Statistical significance tests were assured using odds ratios with a p-value of < 0.05 and a confidence interval of 95%.

Operational Definitions

Exposure duration/time: Is the length of hours that a worker is exposed to any noise level during work time.6

Noise: is an excessive or unwanted sound that potentially results in annoyance and/or hearing loss.10

Permanent threshold shift: Noise-induced threshold shift that persists after a period of recovery after the exposure; at least 3 weeks recovery time.7

Temporary hearing loss: It is a change in the hearing threshold that recovers to pre-exposure levels or baseline over time; the amount of time to recover to baseline may be relatively fast (minutes to hours) or slow (day to weeks).7

Results

Socio-Demographic Characteristics

A total of 388 study participants were included in the study with a response rate of 95.6%. Respondents’ ages ranged from 18 to 49 years, with Mean (± SD) 25.5 (± 4.95) years. Besides, all participants have attained education from primary school to higher education levels, in which 176 (45.4%) were grade 9–10 and 158 940.7%) were at the diploma level and concerning to marital status more than half, 244 (62.9%) of the participants were single (Table 1).

|

Table 1 Socio-Demographic Characteristics of Ayka Addis Textile Factory Workers, Oromia Region, 2019 |

Work-Related Factors Among the Textile Factory Workers

Out of 388 participants, 14 (3.6%) employees in the textile factory were working in other noisy jobs (Flour mills, Garages, and cement factories) before they were started a job at this factory. Smoking was not common in the textile factory, in which only 2 (0.5%) individuals were smokers among the respondents. Similarly, there were only 32 (8.2%) respondents who had the habit of alcohol drink in the textile factory. Regards to work experience, 317 (81.7%) participants had a work experience of 1–5 years and 71 (18.3%) workers had service years of greater than 5 years. The majority of the workers had a working time of 8 hours per day in which there was no overtime work system, but 170 (43.8%) employees from departments of spinning, knitting, and dyeing had a working time of greater than 40 hours per week. In addition to this, 122 (31.4%) workers were engaged in relatively high noise level departments such as spinning and knitting. The work shift schedule in the textile factory was every week/weekly in all production sections. But, workers in the garment department have five working days per week and also no shift schedule among the workers (office hour workers).

The minority of the textile factory workers, 20 (5.2%), and 5 (1.3%) participants respectively had a severe head injury and ear drain problems before they were started a job at the factory. Though, 40 (10.3%) workers reported that there was disturbing noise around their residents from road traffic, mills, and religious institutions. Besides, 24 (6.2%) workers have complained of or the presence of severe headaches confirmed by Physicians before they have started a job at this textile factory (Table 2).

|

Table 2 Work-Related Factors Among Ayka Addis Textile Factory Workers, Oromia, 2019 |

Prevalence of Temporary Hearing Loss Among Workers

The overall temporary hearing loss among the textile factory workers was found to be 49% with (COR=1.53; 95% CI= (1.15–2.03). The workers from the spinning department were 2.38 times more likely to develop temporary hearing loss after exiting from work than workers from the dyeing department (95% CI= (1.16–4.90). Similarly, workers from the knitting department were 3.67 times more likely to develop temporary hearing loss after exiting from work than workers from the dyeing department (95% CI=1.42–9.47). Regarding trouble noise around the ear, spinning workers had 2.17 times more likely to develop the problem than dyeing workers with (95% CI=1.06–4.44). In addition to this, the workers from the spinning department were 3.6 times more likely to suffer from trouble noise around the ear than workers from the garment department (95% CI= 2.14–6.03). In addition to the above associations, the difference in the different symptoms of temporary hearing loss such as difficulty in communication with friends after work, difficulty in phone call conversation, and the problem of normal communication during work time was statistically significant among workers from different textile factory departments (Table 3).

|

Table 3 Prevalence of Temporary Hearing Loss in Ayka Addis Textile Factory Workers, Oromia, 2019 |

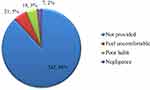

Associated Factors and Temporary Hearing Loss

Working departments were significantly associated with temporary hearing loss among the textile factory workers. Workers who were engaged in the spinning department were 3.55 times more likely to develop temporary hearing loss than workers engaged in the garment section (95% CI=1.72–7.32), workers who were working in the knitting section were 2.48 times more likely to develop temporary hearing loss than workers engaged in the garment department (95% CI=1.46–4.21). Similarly, workers who work greater than 40 hours per week in the factory were 2.1times more likely to develop temporary hearing loss than workers who had 40 hours or less per week (95% CI=1.18–3.70) which was found statistically significant factors (Table 4). In addition to the above-associated factors, none of the textile factory workers have used hearing protective devices. The main reasons mentioned by the participants for none use of hearing protective devices were; 342 (88.2%) reported lack of availability/not provided by the factory and 21 (5.4%) feel uncomfortable using those hearing protective devices (Figure 3).

|

Table 4 Temporary Hearing Loss and Associated Factors Among Ayka Addis Textile Factory Workers, Oromia, 2019 |

|

Figure 3 Reasons for not use of hearing protective devices among Ayka Addis textile factory workers, Oromia 2019 (n=388). |

Workplace Observation

Workplace observation of the study showed that no engineering control was applied to reduce the noise level released from the machines. Regarding personal protective equipment, no individual was using a hearing protective device during work time due to the lack of availability of the equipment in the textile factory. The other observation regarding the noise level was indicated that noise levels in the spinning and knitting were very disturbing and high than that of dyeing and garment departments. Finally, areas with a high noise level in the textile factory were not labeled to keep workers safe from exposing themselves to impulsive noise levels from different machines.

Aerial Noise Exposure Level in the Working Departments

According to the Ethiopian directives agency, there are action limits and exposure limit value for workers. For the lower action limit (80 dBA) there should be information and training to workers and for the upper action limit (85 dBA) hearing protective devices required in the work setting. Besides, for exposure limit value of 87 dBA, there should be hearing protective devices and must not be exceeded to this limit. Workers were exposed continuously to noise exposure levels for an entire eight-hour shift except during a single forty-five minutes meal break. The factory is in use for 24 hours, six days per week. The noise exposure level in the four working departments will be presented in the following table (Table 5).

|

Table 5 Aerial Noise Exposure Level of Different Production Departments in Ayka Addis Textile Factory, Oromia Region, 2019 |

Discussion

This study demonstrated that noise was a serious occupational health hazard in the textile factory. The level of temporary hearing loss among the textile workers, 49% were higher when compared to a study conducted in Sivas-Turkey among textile factory workers; which was 40%.9 This might be due to the textile factory setup, sample size difference, and control measures taken on noise exposure of workers. The higher level of temporary hearing loss in spinning department workers was due to a relatively high noise level than dyeing and garment departments. This might be due to exposure to eight-hour time for a relatively high noise level leads workers to have trouble noise around their ear/head for a long time after exiting from the workplace.

Besides, 44.85% of workers had difficulties in phone call conversations which was higher when compared to a study conducted among individuals in the United Arab Emirates (UAE) in which 14% of students had difficulty in hearing telephone conversations.11 This higher variation might be due to the unavailability of hearing protective devices, the approach of data collection, and institutional setup. In this study majority, about 73.7% of workers had complained about the interference of noise level in their day-to-day normal conversations with co-workers. This problem was approximately similar to a study conducted in two textile plants of Northern India in which 70% of workers reported noise as the major factor causing speech interference.1

The major risk factors for temporary hearing loss were the duration of exposure and the noise level. This relationship was similar to previous studies in India and the Republic of Korea.1,12

In these studies in areas of high noise level, the temporary hearing loss was high and workers who had exposed for a long working time were suffering this occupational problem than workers with less exposure time.

The personal protective equipment utilization behavior of the textile factory workers was low. However, the majority of the workers agreed on the importance of hearing protective devices for preventing themselves from high noise levels emitted from the machines, but the textile factory does not supply hearing protective devices for workers who were in line with the result of a study conducted in Ethiopia among Dire-Dawa textile factory workers.13

Limitation of the Study

One of the limitations of the study was the use of self-administered questionnaires to identify the magnitude of temporary hearing loss symptoms of workers in which it can lead to the overestimation of the problem. Besides, since the study was cross sectional it will not show the cause-effect relationship of the problem.

Conclusion and Recommendations

Generally, temporary hearing loss was found higher among spinning workers than dyeing and garment workers. The working department and length of working hours were the determinant factors for the occurrence of temporary hearing loss. None of the employees in the textile factory were provided hearing protective devices which is the last option for controlling and preventing noise exposures. In general, the results of this study concluded that workers working in the spinning and knitting production departments without using hearing protective devices were harmed the most. Since it is important to prevent workers from leaving their workplace due to different noise exposure-related health problems; our countries regulatory bodies have the opportunity to use this study as a starting point to assess what is happening in the textile factories of the country regarding workers health in general and specifically to noise-related health problems among the workers. Though, the textile factory should provide hearing protection devices to the workers to reduce the prevalence of this hearing problem. Besides, further studies should be conducted by including many types of textile factors and different study designs with audiometric measurements of the hearing capacity of workers.

Abbreviations

AOR, Adjusted odds ratio; dB (A), A weighted decibel; COR, Crude odds ratio; ETB, Ethiopian Birr; HPDs, Hearing protective devices; SD, Standard deviation; SLM, Sound Level Meter; SPSS, Statistical package for social science; TTS. Temporary threshold shift.

Data Sharing Statement

The datasets used and/or analyzed during this study are available from the corresponding author on a responsible request.

Ethical Approval and Consent to Participate

The study was conducted following the declaration of Helsinki on human subjects. After the purpose, benefit and risk were briefed, written informed consent was obtained from the study participants. Ethical clearance was secured by Addis Ababa University Institutional Health Research Ethics Review Committee (IHRERC) and official permission was obtained from Ayka Addis Textile factory, Oromia Health Office, and the Municipal.

Consent for Publication

Not applicable.

Acknowledgments

We would like to acknowledge Addis Ababa University, College of Health Science for all its bits of help. Our grateful gratitude would also go to all the data collectors, supervisors, and study participants.

Funding

There was no funding for this study.

Disclosure

The authors report no conflicts of interest for this work.

References

1. Raman B. Evaluation of Occupational Environment in Two Textile Plants in Northern India with Specific Reference to Noise. 2006;44:112–116.

2. Zerihun S, Mamo H, Sitotaw B, Mengistu E. Evaluation of the people perception of major noise sources and its impact on health at Dire-Dawa city, Ethiopia. Romanian J Biophys. 2017;27:69–78.

3. http://www.euro.who.int/__data/assets/pdf_file/0008/136466/e94888.pdf.

4. Cantley FL, Galusha D, Cullen MR, et al. Association between ambient noise exposure, hearing acuity, and risk of acute occupational injury. Scandinavian J Work Environ Health. 2015;41(1):75–83.

5. Spankovich C, Lobariñas E, Morgenstein KE, et al. Temporary threshold shift after impulse-noise during video gameplay: Laboratory data. 2016.

6. American national institute of occupational health and safety 2006.

7. Ryan FA, Kujawa GS, Hammill T, Prell LC, Kil J. Temporary and permanent noise-induced threshold shifts: a review of basic and clinical observations. 2017.

8. Prell LG, Dell S, Hensley B, et al. Digital music exposure reliably induces temporary threshold shift (TTS) in normal-hearing human subjects. 2012.

9. Atmaca E, Peker I, Altin A. Industrial noise and its effects on humans. Pol J Environ Stud. 2005;14(6):721–726.

10. World Health Organization (WHO). Global Burden of Hearing Loss 2016.

11. Ahmed OH, Ali JA Noise Levels, Noise Annoyance and hearing-related Problems in a Dental College. 2016.

12. Kim J, Lee W, Won J, et al. The relationship between occupational noise and vibration exposure and headache/eyestrain, based on the fourth Korean Working Condition Survey (KWCS). 2017.

13. Ayele B, Yemane B Noise-induced hearing loss among textile workers. 1995.

© 2021 The Author(s). This work is published and licensed by Dove Medical Press Limited. The full terms of this license are available at https://www.dovepress.com/terms.php and incorporate the Creative Commons Attribution - Non Commercial (unported, v3.0) License.

By accessing the work you hereby accept the Terms. Non-commercial uses of the work are permitted without any further permission from Dove Medical Press Limited, provided the work is properly attributed. For permission for commercial use of this work, please see paragraphs 4.2 and 5 of our Terms.

© 2021 The Author(s). This work is published and licensed by Dove Medical Press Limited. The full terms of this license are available at https://www.dovepress.com/terms.php and incorporate the Creative Commons Attribution - Non Commercial (unported, v3.0) License.

By accessing the work you hereby accept the Terms. Non-commercial uses of the work are permitted without any further permission from Dove Medical Press Limited, provided the work is properly attributed. For permission for commercial use of this work, please see paragraphs 4.2 and 5 of our Terms.