Back to Journals » International Journal of Nanomedicine » Volume 16

A Critical Review of the Use of Surfactant-Coated Nanoparticles in Nanomedicine and Food Nanotechnology

Authors Miyazawa T , Itaya M, Burdeos GC , Nakagawa K, Miyazawa T

Received 16 January 2021

Accepted for publication 31 March 2021

Published 9 June 2021 Volume 2021:16 Pages 3937—3999

DOI https://doi.org/10.2147/IJN.S298606

Checked for plagiarism Yes

Review by Single anonymous peer review

Peer reviewer comments 3

Editor who approved publication: Professor Israel (Rudi) Rubinstein

Taiki Miyazawa,1 Mayuko Itaya,2 Gregor C Burdeos,3 Kiyotaka Nakagawa,2 Teruo Miyazawa1

1New Industry Creation Hatchery Center (NICHe), Tohoku University, Sendai, Miyagi, Japan; 2Food and Biodynamic Chemistry Laboratory, Graduate School of Agricultural Science, Tohoku University, Sendai, Miyagi, Japan; 3Institute for Animal Nutrition and Physiology, Christian Albrechts University Kiel, Kiel, Germany

Correspondence: Taiki Miyazawa

New Industry Creation Hatchery Center (NICHe), Tohoku University, 6-6-10 Aramaki Aza Aoba, Aoba-Ku, Sendai, Miyagi, 980-8579, Japan

Tel/Fax +81 22 795 3205

Email [email protected]

Abstract: Surfactants, whose existence has been recognized as early as 2800 BC, have had a long history with the development of human civilization. With the rapid development of nanotechnology in the latter half of the 20th century, breakthroughs in nanomedicine and food nanotechnology using nanoparticles have been remarkable, and new applications have been developed. The technology of surfactant-coated nanoparticles, which provides new functions to nanoparticles for use in the fields of nanomedicine and food nanotechnology, is attracting a lot of attention in the fields of basic research and industry. This review systematically describes these “surfactant-coated nanoparticles” through various sections in order: 1) surfactants, 2) surfactant-coated nanoparticles, application of surfactant-coated nanoparticles to 3) nanomedicine, and 4) food nanotechnology. Furthermore, current progress and problems of the technology using surfactant-coated nanoparticles through recent research reports have been discussed.

Keywords: drug delivery system, drug targeting, food science, food packaging, nonionic surfactants, safety assessment

Introduction

Surfactants have been closely associated to humans for a long time, and these continue to be a necessity in our lives until now. The earliest report regarding the presence of surfactants is the record of soapy traces observed in clay cylinders at the Babylonian archeological site in Mesopotamia in 2800 BC.1,2 Sumerian tablets were excavated from the Mesopotamian archeological site in 2200 BC, and its cuneiform script describes how to make soap from animal fat and ash.1,2 Until the latter half of the 19th century, soap was reported to be the only artificial surfactant. However, in Germany after World War I, soap was found unsuitable for hard or acidic water, and its severe shortage prompted manufacturers to develop new surfactants to meet market demand, resulting in the development of miscellaneous surfactants.3 For example, the synthesis method of sodium dodecyl sulfate (SDS, also named as sodium lauryl sulfate [SLS]), one of the most produced and consumed surfactants until present, was first reported in Germany in 1933 (Figure 1).4 Surfactants have been widely used not only in adhesives, coatings, cosmetics, household detergents, industrial cleaning agents, oil field chemistry, paints, pesticides, plastics, textiles, but also in the fields of food and medicine.5 It was reported in the year 2000 that 4250k tons of detergent and 1190k tons of fabric softener was being consumed each year in Western Europe.6 The global consumption of household detergents in 2016 was 73.4 million tons.7 Due to its wide range of applications and high consumption, the global surfactant market was valued at $43,655 million in 2017 and will reach approximately $64,408 million by 2025.8 In other words, the compound’s annual growth rate from 2018 to 2025 is expected to be +5.4%.8

The concept of “Nanotechnology” was introduced by Richard Feynman in 1959 and named by Norio Taniguchi in 1974; this technology has been applied to nanoparticles, which are progressively being used in medicine and food industries and sometimes referred to as nanomedicine or food nanotechnology, respectively.9,10 Among them, surfactant-coated nanoparticles have been attracting attention in recent years because surfactants provide additional functions to nanoparticles. The present review is aimed to characterize the functions of nanoparticles provided by surfactants. The applications of surfactants, nanoparticles, and surfactant-coated nanoparticles in the field of nanomedicine and food nanotechnology along with some examples are included here. To systematically understand the relationship between the surfactants and nanoparticles, it is necessary to understand each of them individually. Therefore, this review introduces surfactants, surfactant-coated nanoparticles, and applications of surfactant-coated nanoparticles to nanomedicine and food nanotechnology. Through this review, we hope to visualize the current development and associated problems of surfactant-coated nanoparticles, bridge across disciplines, and lay the foundation for the development of new technologies.

|

Figure 1 Classification of surfactants and structures of the ionic and nonionic surfactants mentioned in this review. |

Method

To carry out the literature search, Google Scholar, J-STAGE, MEDLINE, PubMed and Web of Science were employed. The search was based on key words such as surfactant and absorption/accelerated blood clearance/aggregation/aging/Alzheimer’s disease/antimicrobial/antioxidant/antiviral/artificial intelligence/bacteria/bioconcentration/blood-brain barrier/brain uptake/brain/cancer/cationic/cell membrane/cellular uptake/cholate/cholesterol/circulation/clinical trials/coating/DLVO/daily meals/digestive system/drug/drug delivery system/EPR/emulsifiers/emulsion/environmental considerations/environmental pollution/food nanotechnology/food packaging/food quality/food sensing/food technology/gold nanoparticles/health/history/hydrophilic/hydrophobic/inflammation/inorganic/intravenous/ionic/liposomes/liquid/machine learning/medical/medicine/mucus layer/nanoparticles/nanotechnology/nanotoxicology/niosomes/nonionic/opsonization/oral/organic/Ostwald ripening/oxidative stress/P-glycoprotein/phospholipid/plant/poloxamer/polyethylene glycol/polymer/polymeric nanocomposites/polyphenol/polysorbate/process/quantum dots/reactive oxygen species/reticuloendothelial system/SPION/safety/self-assembly/senescence/side effect/silica nanoparticles/silver nanoparticles/smart food/stability/stealth effect/supramolecular structures/surfactant-coated nanoparticles/tissue distribution/toxicity/tween/Van der Waals forces/vesicles/vitamin.

Surfactant

Overview of Surfactant

Surfactants, which is an abbreviation for “surface-active agents,” are classified as amphiphilic compounds due to the presence of both hydrophilic and hydrophobic groups in their chemical structure.11 Depending on the characteristic of the hydrophilic group, surfactants can be broadly classified into four types: Cationic surfactants (positively charged hydrophilic groups), anionic surfactants (negatively charged hydrophilic groups), zwitterionic surfactants (having both positively and negatively charged hydrophilic groups), and nonionic surfactants (the hydrophilic group has no charge) (Figure 1).12 Cationic surfactants contain alkylamine or quaternary ammonium salts in their hydrophilic groups and can be adsorbed on negatively charged interfaces such as keratin (a component of skin and hair), natural fibers, and chemical fibers. They have antistatic and disinfectant properties, and are used as antistatic agents, coating agents, disinfectants, and softeners (hair conditioners and fabric softeners). Anionic surfactants contain carboxylic acid salts, sulfonates, sulfate salts, sulfate esters, or phosphates in their hydrophilic groups and offer good detergency, foaming property, foam stability, and penetration. They are used as foaming agents, paints, protein solubilizers, soaps, and present in various household and industrial detergents. Zwitterionic surfactants contain carboxy betaine, imidazolium betaine, aminoethylglycine salt, or amine oxide in their hydrophilic groups. They are often used as auxiliary materials to enhance the effectiveness of other surfactants or coexisting compounds. For example, anionic surfactant (sodium bis(2-ethylhexyl) sulfosuccinate [AOT], which self-assembles into the shape of ellipsoidal micelles), forms vesicles in the presence of zwitterionic surfactant (oleyl amidopropyl betaine [OAPB], which self-assembles into the shape of worm-like micelles [Figure 1]) and salt.13 Zwitterionic surfactant (3-[N,N-dimethyltetradecylammonio]propane-1-sulfonate [SB3-14] [Figure 1]) enhanced the loadability of natural flavonoid dye (quercetin) in wool and enhanced its antioxidant properties (Figure 1).14 Nonionic surfactants have non-dissociable chemical structures in their hydrophilic groups, such as amides, alcohols, esters, ethers, or phenols. They are used in cosmetics, as food emulsifiers, and skin cleansers due to low irritation and toxicity, which are the most important advantages associated with their application in nanomedicine and food nanotechnology. There are many reports available on the order of toxicity of surfactants, which generally demonstrate that cationic surfactants > anionic surfactants ≥ zwitterionic surfactants > nonionic surfactants, although toxicity may vary depending on the chemical structure.15–19 This is owing to the fact that the hydrophilic groups of nonionic surfactants do not ionize in aqueous solutions, and thus the critical micelle concentration of nonionic surfactants tends to be much lower than that of ionic surfactants. Therefore, they are less toxic than ionic surfactants. The hydrophobic groups of nonionic surfactants are composed of long-chain fatty acids and water-insoluble derivatives and are classified as fatty alcohols, esters, ethers, and block copolymers.20,21 Among the surfactants of one group, toxicity generally correlates with the ability of surfactant molecules to migrate from water to cell membranes.22 Therefore, the surfactant that has a longer chain length of the hydrophobic group and higher hydrophobicity can easily move to the lipid bilayer composed of phospholipids. Therefore, these are considered more toxic than highly hydrophilic surfactants.22 Henceforth, nonionic surfactants are most frequently used in the fields of nanomedicine and food nanotechnology. Currently, various nonionic surfactants are commercially available, so consumers can choose suitable compounds depending on their purpose.

In a system consisting of a single phase, surfactants are dispersed and equilibrated in the bulk. On the other hand, surfactants initiate their interactions after modification of various conditions such as electrolyte concentration, surfactant concentration, pH, pressure, temperature, and type of solvent. This leads to supramolecular self-assembly of bilayer membrane vesicles, cylindrical micelles, lamellar phases, spherical micelles, etc.23 In addition, when the system consists of multiple phases, surfactants stabilize them due to their inherent physical characteristic of being localized at the interface (for example, air and water, oil and water, solid and water) due to their amphipathic chemical structure. In the absence of a surfactant, the molecules present in the respective aqueous and oil phases exert high surface tension due to intermolecular forces (such as hydrogen bonds), and the system is separated into different phases. When the surfactant is localized at the interface, an intermolecular force acts between the hydrophilic group of the surfactant and water molecule, thereby decreasing interfacial tension and surface tension leading to formation of supramolecular structures such as dispersed phase (such as emulsion) and continuous phase (such as bicontinuous liquid crystals) and a drastic change in the ratio of surface area to volume. The hydrophilic-hydrophobic balance (HLB, a parameter that indicates the surfactant’s affinity for water and oil) and the critical packing parameter (CPP, a parameter that predicts the surfactant’s self-assembly) are used to predict the properties of the surfactant.24–27 The “nanoscale supramolecular structures composed of surfactants” as discussed above, have been used as templates for the synthesis of inorganic materials28,29 enhancement of the activity of catalysts,30 reaction field of nanoreactors,31 modulation of wettability of biological interfaces,32 and enhanced oil recovery from heterogeneous rocks.33

Nonionic Surfactants in the Pharmaceutical Industry

The advantages of nonionic surfactants such as low cost, high stability, low toxicity, and amphiphilic nature can be used as next-generation materials and an alternative to applications of phospholipid-based nanostructures (hybrid lipid particles, nanocontainers, nanopores, and transistors).34 Due to these advantages, the field of nanomedicine is investigating the use of niosomes (vesicles composed of nonionic surfactants) instead of liposomes, which are composed of phospholipids and are widely used as carriers for drug and gene delivery.35 Bartelds et al prepared fluorophore (calcein)-encapsulating niosomes consisting of nonionic surfactants (polysorbate 80 [polyoxyethylene (20) sorbitan monooleate, also named as tween 80 [Figure 1]], sorbitan monostearate, and cholesterol).36 And compared their leakage to that of liposomes (consisting of phospholipids and cholesterol) after 25 h of incubation. The results showed that 10% of calcein leaked from the liposomes, whereas less than 3% of calcein leaked from the niosomes. This indicates that niosomes could retain the encapsulated material for a longer period. Puras et al prepared cationic niosomes consisting of cationic lipids and nonionic surfactants (polysorbate 80).37 They reported lower toxicity during transfection of cells with niosomes than with Lipofectamine®, which is commonly used in gene transfer techniques. In addition, nonionic surfactants are widely used in protein drug delivery because they can stabilize proteins against interfacial tension and minimize the adsorption and aggregation of proteins at the interface.38,39 Li et al demonstrated that the presence of nonionic surfactants (polysorbate 80 and poloxamer 188 [poly(ethylene glycol)-block-poly(propylene glycol)-block-poly(ethylene glycol), also named as pluronic F68] [Figure 1]) inhibited the irreversible adsorption of abatacept on silicone oil used as a lubricant for medical syringes with polysorbate 80 being more effective.40 Furthermore, poloxamers are used in more than 70% of commercially available monoclonal antibody drug delivery due to their ability to inhibit self-assembly and aggregation of antibodies.41–43 Moreover, the use of nonionic surfactants as pharmaceutical products is also being considered. For example, nonoxynol-9 has been found to have the potential for human immunodeficiency virus type 1 (HIV-1) infection and as topical disinfectant, but its efficacy has not been confirmed in clinical practice.44,45

Nonionic Surfactants in the Food Industry

Approximately 75% of the total emulsifiers in the global food industry are mono- and di-glycerides, widely recognized as nonionic surfactants, either emulsifiers are industrially produced.46 Mono- and di-glycerides have been widely used as antimicrobial agents, antidegradants, emulsifiers, preservatives, and thickeners in food products such as beverages, ice cream, margarine, and shortening. Mono- and di-glycerides are also reported to be present in trace amounts in natural food resources, such as paprika seed oil, pumpkin seed kernel oil, and watermelon seed kernel oil, which contain approximately 1% (proportion of total lipid) monoglycerides, and 0.3% (proportion of total lipid) diglycerides (Figure 1).47,48 The use of nonionic surfactants as food emulsifiers that enhance the absorption of fat-soluble food ingredients when taken orally is widely recognized.49 It is generally believed that emulsions have higher digestibility than other forms because they have more surface area to react with digestive enzymes, such as lipase. Salvia-Trujillo et al prepared emulsions with different particle sizes (small: 0.12 μm, medium: 0.19 μm, and large: 14 μm) containing lipophilic food component (β-carotene), and demonstrated the effect of particle size on its absorption using a gastrointestinal tract model.50 The results showed that the rate of digestion of lipids present in emulsions increased with decreasing particle size (small = medium > large) along with increased absorption of β-carotene (small > medium > large). To understand the mechanism of enhanced absorption, Lu et al prepared β-carotene encapsulated emulsions containing sunflower oil with monoglycerides in the range of 0–2% and demonstrated that the uptake of β-carotene into human colorectal adenocarcinoma (Caco-2) cells increased as the percentage of monoglycerides increased.51 They reported the mechanism of reduction in the surface charge of the emulsion in gastric fluid environment due to the presence of monoglycerides, which leads to an increase in the amount of lipase adsorbed onto the surface of the emulsion and reduction of creaming (a phenomenon in which thermodynamically unstable emulsions undergo phase separation over time). The antimicrobial effect of food ingredients is also known to be enhanced by coexistence with monoglycerides. Lee et al. found that the antimicrobial effect of linolenic acid on Bacillus cereus and Staphylococcus aureus was enhanced by coexistence with monoglycerides.52 They reported that the mechanism was that monoglycerides localized on the cell membrane of the bacteria enhanced the adhesion of linolenic acid to the cell membrane. Moreover, monoglycerides have been confirmed in synthesis-based scientific approaches to enhance the biological activity of food components. For example, omega-3 fatty acids are known to have useful physiological effects such as anti-inflammatory, antioxidant, anticancer, and anti-obesity and are available in the market as oral supplements, although they are known to be chemically unstable, difficult to dissolve in water, and have low absorption. To solve these problems and to enhance the physiological effects, eicosapentaenoic acid-monoglyceride, docosahexaenoic acid-monoglyceride, and docosapentaenoic acid-monoglyceride (in which eicosapentaenoic acid, docosahexaenoic acid, docosapentaenoic acid were esterified and bound to the sn-1 position of the glycerol moiety in the monoglyceride structure) have been studied.53,54 In addition to these applications, nonionic surfactants are used in a variety of applications in the food industry and are detailed in other reviews.55,56

Surfactant-Coated Nanoparticles

Nanoparticles have been used in the fields of nanomedicine and food nanotechnology to impart a variety of functions to encapsulated compounds. However, depending on the surface structure, the prepared nanoparticles are difficult to disperse in water and be aggregated in a short time. An approach to solve this problem is to allow coexistence of the prepared nanoparticles and the surfactant so that the surface of the nanoparticles is covered with the surfactant, and the nanoparticles are stabilized in the system. These nanoparticles are called “Surfactant-coated nanoparticles” (Figure 2A).57,58 It is important to understand the interaction between the nanoparticles and the surfactant in surfactant-coated nanoparticles for their efficient performance.

|

Figure 2 (A) Typical Illustration of surfactant-coated nanoparticles. (B) Various organic and inorganic materials used in the core of surfactant-coated nanoparticles. |

The nanoparticles exert forces on each other. Orientation interactions (Keesom interactions), dipole interactions (Debye interactions), and dispersion interactions (London interactions) are collectively called “van der Waals forces” and are responsible for intermolecular interactions.59 Van der Waals forces acting between particles are considered to be caused by the attractive forces between the molecules present in each particle and are expressed by the equation (Figure 3A (1)),60 where AH is the Hamaker constant that varies depending on the type of molecules present in the particles, for example, the value of Hamaker constant is 6.5×10−20 J for poly (lactic-co-glycolic acid) (PLGA), and in the range of 0.9–3.0×10−19 J for gold.61,62 As the size, shape, and temperature of metallic particles change, the value of the Hamaker constant also changes due to the change in the dielectric constant.62 The above equation is approximated to the equation (Figure 3A (2)) by the Derjaguin approximation by assuming that the distance between the two particles is narrower than the radius (Figure 3B).63 It can be inferred from these equations that the van der Waals force between particles becomes weaker as the distance between the particles increases and becomes stronger as the size of the particles increases.

The surface charge between particles is also important as it determines the electrostatic repulsive force. Particles that are positively or negatively charged in solution form an ionic atmosphere due to the attraction of counter ions to the surface of these particles, resulting in the formation of an electric double layer. When particles come close to each other, the overlap of the electric double layer leads to a change in the ion concentration and the repulsive force is generated. This phenomenon is called “electrostatic repulsive force.”62,63 Models of the strength of this electrostatic repulsive force include Helmholtz, Gouy-Chapman, Stern, and BDM (Bockris/Devanathan/Muller), each of which has been formulated.64 One of the most widely used equations for the electrostatic repulsive force is for colloidal systems with dispersed nanoparticles (Figure 3A (3)).65 The theory that considers both the “attractive force” of the van der Waals interaction and the “repulsive force” of the electrostatic repulsion is called the Derjaguin-Landau-Verwey-Overbeek (DLVO) theory.63,66,67 DLVO theory is named after the scientists who contributed to its development and can explain the coagulation/dispersion state of particles. In DLVO theory, the stability of a colloid is defined as the total sum of van der Waals force and electrostatic repulsion force between particles, and the total potential energy and is expressed as shown in Figure 3A (4–7).62,65,68

A typical example of the DLVO theory is shown in Figure 3C.60,63,65 At high potential energy, the particles are stable because they repel each other (Figure 3C (i)). As shown in Figure 3C (ii), if there is a deep secondary minimum, the particles are in a stable equilibrium state. As shown in Figure 3C (iii), when the secondary minimum is shallowly declined the particles gradually aggregate. As shown in Figure 3C (iv) and (v), if the attractive van der Waals force is stronger than the electrostatic repulsive force, the particles will aggregate in a short time. To elucidate the influence of surfactant adsorption on the aggregation behavior of nanoparticles, Farrokhbin et al dispersed three types (amidine latex, silica, and sulfate latex) of nanoparticles in non-polar solvent (decane) and added an anionic surfactant (SDS) and assessed the parameters for aggregation based on the DLVO theory (shielding distance, surface charge, and van der Waals force).69 As a result, they reported an increase in inhibition of aggregation and stabilization of dispersion in a concentration-dependent manner until the concentration of anionic surfactant in the system reached a certain concentration. Espinosa et al also reported that the dispersion of poly (methyl methacrylate) nanoparticles was stabilized in non-polar solvents (hexane) when a nonionic surfactant (sorbitan trioleate, also named as Span 85) was present in the system.70 Although, the DLVO theory is adaptable to particles of hard materials, however, there are limitation in its applicability to soft materials such as cells and lipoproteins, causing different dispersion phenomena in vivo.71,72 Therefore, additional theory will need to be developed. If there is a difference in the size of the particles in the system, the smaller particles are incorporated into the larger particles over time due to the difference in their surface energies, with the larger particles becoming larger and the smaller particles disappearing from the system. This phenomenon is known as “Ostwald ripening” and is widely recognized as a principle that applies to all organic and inorganic particles.73 As mentioned at the beginning of this section, particle agglomeration is a concern in particle dispersion systems. However, it has been reported that the presence of a surfactant in the system induces it to get adsorbed to the surface of the particles and lowers the speed of ripening by several orders of magnitude.74 Kiss et al demonstrated the mechanism of adsorption of nonionic surfactants (pluronic PE6100, PE6400 and PE6800) on hydrophobic interfaces (blend film composed of polylactic acid [PLA] and PLGA).75 They reported that highly hydrophilic surfactants could not adsorb to the hydrophobic interface, while surfactants with both high and low hydrophilic moieties could adsorb and distribute effectively to the hydrophobic interface. The presence of surfactants at the solid interface increased steric stabilization. When the nanoparticles come close to each other, the hydrophobic groups of the surfactant on the surface of the nanoparticles limit the mutual penetration, resulting in steric hindrance and stabilization. Steric stabilization is different from electrostatic repulsive forces, such as being unaffected by the electrolyte concentration of the solvent and adaptable over a wide range of nanoparticle concentrations.76 Santander-Ortega et al studied in detail the adsorption and stabilization mechanism of nonionic surfactants on PLGA nanoparticles and confirmed that a nonionic surfactant (poloxamer 188) adsorbed to the interface of PLGA nanoparticles when both of them coexisted.77 Moreover, they demonstrated that as the adsorption of nonionic surfactant (poloxamer 188) on the surface of PLGA nanoparticles increased, the steric stability of nanoparticles was greatly increased by the polyethylene oxide framework in nonionic surfactant, and the parameters of the DLVO theory indicated the formation of a stable dispersion. Furthermore, surprisingly, they found that the stabilization mechanism is not only explained by the DLVO theory and steric stabilization, but also dependent on the repulsive hydration forces to the hydrophilic interface constructed by nonionic surfactant (poloxamer 188) on the surface of nanoparticles. Since the stabilization by the repulsive hydration force is unaffected by the external salt concentration, the system is also expected to be stable in vivo and is attracting attention. Chaudhari et al and other researchers reported that an anionic surfactant (SDS) and a nonionic surfactant (poloxamers) had little effect on the release rate of the encapsulated drug from the solid dispersions.78–81 Conclusively, surfactants play an important role in the stabilization of nanoparticles and there are many applications of surfactant-coated nanoparticles as explained in the next section.

Application of Surfactant-Coated Nanoparticles in Nanomedicine

Nanomedicine

Nanotechnology is defined as the deliberate design, characterization, production, and application of materials, structures, devices, and systems by controlling their size and shape within the nanoscale range.82

Nanomedicine is regarded as “the use of nanoscale material properties and physical characteristics for the diagnosis and treatment of diseases at the molecular level”.82 According to a report of 2013, 789 clinical trials were in progress at 241 companies and research institutions, and 363 nanomedicine products and applications were identified.83 In the field of nanomedicine, surfactants are often used to impart new functions to nanoparticles. Recent progress in this field is summarized in Table 1. In the following sections, nanomedicine based on surfactant-coated organic and inorganic nanoparticles will be presented and the properties each nanostructure will be discussed separately. However, in practice, most approaches combine multiple materials and properties rather than only one. Therefore, in the field of nanomedicine, it is necessary to have integrated knowledge and approaches that are not limited to the respective organic and inorganic fields of expertise.

|  |  |  |  |  |  |  |  |  |  |  |  |

Table 1 Summary of Surfactant-Coated Nanoparticles Used in the Field of Nanomedicine |

Surfactant-Coated Organic Nanoparticles in Nanomedicine

During disease treatment, the administered molecule (drug) can exhibit a therapeutic effect only when it reaches the target site of action, such as an area of inflammation or a cancer tissue. However, when a free drug is administered into the bloodstream, its therapeutic efficacy is severely limited due to various problems including premature degradation, expulsion of the drug due to the reticuloendothelial system (RES, also called the mononuclear phagocyte system [MPS]), degradation due to instability of the drug, poor dispersibility, and poor accumulation at the site of action. The resulting non-selective tissue distribution of drugs is a major factor responsible for drug toxicity (for example, dose-limiting toxicity [DLT]).84 Organic nanoparticles, which are widely used in the field of nanomedicine, have potential to overcome the above problems because they can impart a variety of advantages to the encapsulated substances.85 For example, organic nanoparticles encapsulating anticancer drugs, genes, and proteins can be delivered selectively to the target site of action or specific cells while protecting the encapsulation from degradation and RES; such a technology increases therapeutic efficacy and reduces side effects and is called a “drug delivery system”.86–88 The constituents of the organic nanoparticles used in the drug delivery system are selected to be non-toxic or low-toxic to living organisms, and typical examples include biodegradable polymers (chitosan, gelatin, hyaluronic acid, PLGA, poly[alkyl cyanoacrylate], and poly-ε-caprolactone), solid lipids (cetyl palmitate, cholesterol, palmitic acid, stearic acid, and tristearin), and proteins (albumin, collagen, gliadin, legumin, protamine and silk) (Figure 2B).89–91 A number of methods for preparing organic nanoparticles have been reported, and the related mechanism has been reviewed in detail by Anton et al.74 For example, the emulsification solvent evaporation technique (polymer- and lipophilic drug-containing organic solvent is dispersed in surfactant-containing water to form an oil in water [O/W] emulsion as a template of nanoparticles, and then evaporated to precipitate polymeric nanoparticles containing the drug dispersed into the system) is widely used to prepare nanoparticles composed of biodegradable polymers, and the microemulsion method (oil phase containing low melting temperature lipid and lipophilic drug is dispersed in surfactant-containing water to form O/W microemulsion as a template of nanoparticles, which is then rapidly cooled to precipitate drug-containing solid lipid nanoparticles) is widely used to prepare nanoparticles composed of solid lipids.90,92 The preparation of PLGA nanoparticles by solvent evaporation technique is widely used, and the most commonly used surfactant in the preparation process is polyvinyl alcohol (PVA).93 Pisami et al used three different surfactants (PVA, sodium cholate [SC] [Figure 1], sodium taurocholate [TC], [Figure 1]) in the preparation of PLGA nano/micro particles encapsulating lipophilic substances (perfluorooctyl bromide [PBOB]) by solvent evaporation technique (dichloromethane was used as the organic phase) and compared their detail of precipitation process by optical microscopy, confocal microscopy and transmission electron microscopy (TEM).94 The results showed that in the TC group, the precipitated particles showed acorn shaped (PBOB and PLGA individuals precipitated independently) morphology, while in the PVA group, both acorn and core-shell shaped morphologies were precipitated. As the reason for the difference in particle deposition morphology, they found that PVA forms a stable phase at the dichloromethane-water interface but has properties that prevent PLGA molecules from adsorbing to the interface, while TC does not allow other chemical species to adsorb at the interface. On the other hand, in the SC group, a mixed interface of PLGA molecules and surfactant was formed during particle formation, and particles with a core-shell shaped morphology were stably deposited in the system. Therefore, they concluded that when preparing particles by solvent evaporation technique, core-shell morphology was obtained if PLGA molecules could be adsorbed on the mixed interface, otherwise acorn shaped morphology was obtained. The coexistence of different surfactants may be useful in the formation of particles. Ramirez et al reported that when PLGA nanoparticles were prepared by the solvent evaporation technique, the presence of not only PVA but also other surfactant (SDS) leads to steric stabilization in the systems, resulting in the precipitation of PLGA nanoparticles with a smaller particle size than those prepared by PVA alone.95 Such findings suggest that surfactants play a critical role in the preparation of nanoparticles. The prepared nanoparticles were administered in vivo after their stability, interactions with proteins and cells have been thoroughly investigated in vitro.96

Surface Charge and Protein Adsorption

The charge on the surface of the nanoparticles has an important influence on their intracellular localization. Compared to anionic and nonionic charged nanoparticles, cationic charged nanoparticles exhibit higher cellular uptake due to their enhanced adhesion to the surface of negatively charged cells by electrostatic attraction.97–99 It has also been reported that cationic charged nanoparticles incorporated into cells have the ability of endosomal escape. Lipid nanoparticles composed of ionized amine lipids with a pKa of 6–7 and tertiary amines have an electrically neutral surface charge in the blood (pH 7.4) but become cationic in the endosomal environment (pH < 6.5) after they are taken up into the cell. As a result, cationic charged nanoparticles fuse with the negatively charged endosomal membrane and release encapsulated drugs into the cytoplasm.100–102 By this mechanism, cationic surfactants such as cetyltrimethylammonium bromide (CTAB) and didodecyldimethylammonium bromide (DDAB) are used to provide a positive charge to the surface of nanoparticles (Figure 1). Fay et al prepared cationic charged surfactant-coated nanoparticles (PLGA nanoparticles encapsulating plasmid DNA covered with cationic surfactant [DDAB]) and assessed their transfection efficiency into murine macrophage (RAW 264.7) cells, and observed an increase in cellular uptake and endosomal escape; transfection was achieved with a one thousandth amount of plasmid DNA compared to that of commonly used transfection reagent Lipofectamine®.103 In addition, cationic charged nanoparticles showed a stronger immune response than anionic charged and nonionic nanoparticles, which have attracted attention in recent years for the development of vaccines and application in the field of immunotheraphy.104,105 Kedmi et al prepared cationic charged surfactant-coated nanoparticles (small interfering RNA [siRNA] encapsulated in solid lipid nanoparticles coated with a cationic surfactant [1, 2-dioleoyl-3-trimethylammonium-propane (DOTAP)]) and observed the activation of the innate immune system in C57BL/6 mice.106 The results showed a 10- to 75- fold higher induction of type 1 helper (Th1) cytokine expression than the control particles (weakly anionic charged). However, cationic charged nanoparticles are more likely to disrupt cell membrane integrity and cause damage to mitochondria and lysosomes than anionic charged and nonionic nanoparticles, which raises concerns about their side effects.107 It has also been reported that the surface of cationic nanoparticles is prone to non-specific adsorption of albumin and alpha-1B-glycoprotein.108,109 Furthermore, as mentioned in section “Overview of Surfactant” of this review, the cationic surfactant itself has potential toxicity; approaches to avoid this toxicity have been reported, for example, Gossmann et al observed reduced side effects when the surface of PLGA nanoparticles coexisted with nonionic polymers (polyethylene glycol [PEG]) and cationic surfactant (DDAB) in vitro.110 The RES is actively involved in the phagocytosis of macrophages in the spleen, bone marrow, and liver.111–113 Nanoparticles administered into the bloodstream bind to proteins and antigens called opsonin, forming a corona (a complex of nanoparticles, proteins, and antigens), which is taken up by macrophages. This phenomenon is called “opsonization”, and the process involves apolipoprotein, albumin, fibrinogen, immunoglobulins, and complement components.114 The opsonized nanoparticles interact with receptors on the surface of macrophages and are transported to phagosomes and fused with lysosomes for degradation or elimination from the body.111 It has been reported that PLGA nanoparticles, which are not coated with any surfactant, are opsonized by non-specific adsorption of plasma proteins on their surface, which leads to their degradation in the body (Figure 4A).115 Moreover, targeting ligands present on the surface of the nanoparticles are masked by opsonization, which reduces their targeting ability. Salvati et al prepared silica nanoparticles modified with transferrin on its surface as a targeting ligand for receptor (transferrin receptor) on cancer cells and reported that the opsonized form of these nanoparticles lost their targeting ability.116 Hence, it is critical to avoid opsonization for effective targeting ability of nanoparticles in vivo and to reach the target site of action. Furthermore, it has been discovered that the nanoparticles coated with nonionic surfactants, such as poloxamers, avoid opsonization and predation by macrophages (this phenomenon is also called as “stealth effect”) (Figure 4B). Currently, PEG modification of nanoparticles is the most widely used method to impart stealth effect to nanoparticles, but the continuous administration of PEG-modified nanoparticles has raised concerns about the accelerated blood clearance (ABC) phenomenon (an immune response-induced mechanism to remove PEG-modified nanoparticles from the body).117–119 Su et al synthesized PEGylated surfactant by conjugation of surfactant (cholesteryl methyl amide) to PEG.120 They have reported that nanoemulsions composed of PEGylated surfactant showed weak ABC phenomenon in male Wistar rats. In the future, the properties of surfactants will be pursued more deeply, and surfactants that can modify the function of PEG and weaken the ABC phenomenon will be found. Jain et al prepared iron-encapsulated PLGA nanoparticles by optimizing the surface modification with a nonionic surfactant (poloxamer 188) using adsorption isotherm models (Langmuir, BET, Freundlich, Henderson, and Halsey models).121 The uptake of these surfactant-coated nanoparticles into murine macrophage (RAW 264.7) cells was compared with that of bare nanoparticles. The results revealed no cellular uptake of surfactant-coated nanoparticles after one hour of incubation. Liao et al prepared surfactant-coated nanoparticles composed of retinoic hydroxamic acid coated with nonionic surfactants (poloxamer 184 and 188) and observed their anticancer activity in subcutaneous melanoma (A375) mouse model.122 They reported that surfactant-coated nanoparticles exhibited a stealth effect in the body of mice, and showed enhanced anticancer activity due to increased accumulation in cancer cells and decreased accumulation in the liver during the 16 h observation period, compared to bare nanoparticles. The principle mechanism by which poloxamer-coated nanoparticles exerted a stealth effect is due to the influence of PEG and polyoxyethylene oxide (PEO) moieties in chemical structure of poloxamer.123,124 Surfactants and polymers with PEG, PEO, and polypropylene oxide (PPO) moieties are known to inhibit the adsorption of opsonins by building a hydrophilic barrier on the surface of the nanoparticles and by free movement and steric hindrance due to the construction of a polymer brush structure.125–128 This stealth effect has been observed not only with poloxamers but also with other nonionic surfactants having PEG and/or PEO moieties. For example, Zhao et al prepared surfactant-coated nanoparticles (gold nanoparticles covered with a nonionic surfactant [polysorbate 80]) and reported that adsorption of opsonization-related substances (bovine serum albumin [BSA], fibrinogen, γ-globulins, immunoglobulin G [IgG], and lysozyme) on surfactant-coated nanoparticles in phosphate buffer was inhibited, and no aggregation was observed for 24 hours.129 On the other hand, there is a theory of the mechanism of the stealth effect of nonionic surfactants related to change in the conformation of the opsonins attached to the surfactant. Torcello-Gómez et al prepared surfactant-coated nanoparticles (polystyrene nanoparticles covered with a nonionic surfactant [poloxamer 188]) and confirmed their adhesive dynamics with IgG, which is a typical example of opsonin.130 They reported that the adhesion of IgG on the surface of surfactant-coated nanoparticles was only slightly inhibited compared to bare nanoparticles, and 80% of the surface area was covered by IgG. However, the conformation of IgG that adhered to nonionic surfactants changed, suggesting that the suppression of opsonization is not due to adhesion but due to conformational changes in IgG. Although imparting the stealth effect to the nanoparticles by using nonionic surfactants is easy and bears low cost, but the potential problems need to be solved. One of such problem is the possibility of detachment of surfactants from the nanoparticles and causes unexpected side effects in vivo; the physiological effects of the autoxidized and hydroxylated products of nonionic surfactants, and their complement activation in vivo are largely unknown. 76,131–133 One way to address these concerns might be to optimize the interaction between the encapsulated drug and the materials of the nanoparticles. Gagliardi et al compared zein and PLGA as suitable materials for the preparation of nanoparticles encapsulating lipophilic flavonoid (rutin).134 The results showed that the interaction between rutin and zein exhibited longer drug release kinetics in the zein group compared to the PLGA group, and this effect was most effectively demonstrated when sodium deoxycholate monohydrate (SD) was used in the preparation of nanoparticles. In the future, more useful surfactant-coated nanoparticles will be developed by further optimizing the compatibility of the encapsulated drug, nanoparticle material, and coating surfactant.

|

Figure 4 Behavior and fate of surfactant-coated nanoparticles in the blood stream. Notes: (A) Bare nanoparticles. (B) Poloxamer 188 coated nanoparticles. (C) Polysorbate 80 coated nanoparticles. |

Active and Passive Targeting

In addition to the adsorption and surface modification of the nanoparticles, the particle size is a major factor governing the behavior of nanomedicine. It is generally accepted that the desired particle size for solid particles administered as drugs for circulation in the bloodstream is 10–200 nm (Figure 5A).135 Particles smaller than 100 nm in size are known to avoid phagocytosis by the RES and have been reported to circulate in the bloodstream for a relatively long time.136–138 On the other hand, since the diameter of capillaries in the body is 3–9 μm, particles larger than that size can clog capillaries and unintentionally accumulate in organs with large surface areas of capillaries, such as the lungs.139 Kutscher et al found that particles with a size of 6 μm or larger accumulated in the lungs for more than a week when polystyrene microparticles of different particle sizes (2, 3, 6, and 10 μm) were administered intravenously to rats.140 In addition, particles larger than 400 nm in size were captured by splenic filtration, and then removed and degraded by red pulp macrophages.141 Conversely, it has been also reported that too small particle size can make it difficult to circulate in the bloodstream. Particles smaller than 15 nm are filtered out of the bloodstream by the kidneys and removed from the bloodstream.142 As the average effective pore size of normal vascular endothelial cell is approximately 5 nm, some reports suggest that particles with a size smaller than 5 nm leak out of vascular endothelial cells and accumulate at unintentional sites, causing them to disappear from the bloodstream in a short time.143 Particle size is also important in the development of cancer-targeting drug delivery systems. One of the most recognized cancer-targeting effects is the enhanced permeability and retention (EPR) effect, which was reported by Matsumura and Maeda in 1986.144 The following two phenomena are collectively referred to as the EPR effect: (1) the presence of gaps in the new blood vessels around the tumor due to an incomplete vascular endothelial system, which allows nanoparticles to pass through the vessel wall and accumulate in the tissue; and (2) long-term accumulation of nanoparticles in the tumor tissue due to insufficient intratumoral exclusion system consisting of immature lymphoid tissue in cancer cells than in normal cells (Figure 5B). The EPR effect is referred to as “passive targeting” because it does not require surface modification with targeting ligand. The EPR effect is reported to be exhibited by particles having size of 100–400 nm.145 Based on this mechanism, a number of studies on cancer targeting chemotherapy using nanoparticles with a particle size of 400 nm or less have been reported to date.146–150 On the other hand, many researchers believe that EPR effect alone is not sufficient to achieve cancer-targeting therapeutic effect of nanoparticles, and further enhancement is required, as observed in some gastric and pancreatic cancers.151 Sindhwani et al reported in 2020 that the accumulation of nanoparticles in solid tumors is dominated via trans-endothelial pathways than by EPR effects, which has attracted much attention.152 In addition to the EPR effect, “active targeting” has been widely attempted to further enhance the therapeutic effects of nanoparticles. Active targeting refers to the modification of nanoparticles with targeting ligands (antibodies, aptamers, carbohydrates, macromolecules, proteins, and small molecules) for cancer cell-specific targets (antigens, lipid components, receptors, or proteins on the cell membrane). The drug encapsulated in the nanoparticles modified with the targeting ligand accumulates around the tumor tissue by the EPR effect (passive targeting) and is delivered and accumulated at the target site of cancer cells through response, affinity, and binding by the molecular site, shape, and stimulation (such as pH, temperature, and ultrasound) (Figure 5C and D).153,154 Tumors with a volume of less than 100 mm3 have insufficient vascular endothelial gaps and are recognized as less effective for drug accumulation via EPR effect, while active targeting is regarded as effective in treating such small tumors and other diseases.155 Acharya et al prepared rapamycin-encapsulated PLGA nanoparticles.156 They reported that when their surface was modified with epidermal growth factor receptor monoclonal antibodies (EGFR mAb) (passive targeting + active targeting), their uptake into malignant breast cancer (MCF-7) cells was 13-fold higher than that of bare (passive targeting only) nanoparticles. Poom et al prepared PEG nanomicelles containing anticancer drug (paclitaxel) and reported that the accumulation of paclitaxel in rat tumor tissue decreased to 1% ID/g of tissue after 3 days when the PEG nanomicelles were administered (passive targeting only), whereas the drug accumulation of more than 5% ID/g of tissue was maintained even after 5 days when the PEG nanomicelles modified with folate ligands were administered (passive targeting + active targeting).157 However, excessive surface modification of nanoparticles with targeting ligands is thought to result in poor targeting to cancer cells due to the following factors: (1) decrease in the stealth effect due to the reduced surface exposure of molecular sites such as PEG, PEO, and PPO, (2) decrease in the EPR effect with the increase in particle size, (3) reduced diffusion of nanoparticles in cancer tissue, (4) decrease in the ability to bind to cancer cell-specific targets due to steric hindrance between targeting ligands, and (5) a decrease in the number of particles taken up by increasing the receptor occupancy per particle (Figure 5D).158 Therefore, it is suggested to optimize the density of the targeting ligands for specific cancer cell targeting for maximum interaction between nanoparticles and target cells. Recently, several nanomedicine products based on nanoparticles have been approved by the Food and Drug Administration (FDA).159,160 Although the field of research on nanoparticle-based drug delivery systems is developing rapidly, there are many concerns that need to be considered in the future, especially when nanoparticles are not distributed within the tumor microenvironment depending on the condition of cancer,161 expression of surface receptors varies depending on the diversity of cancer (for example, active targeting not working well for cancer stem cells),162 and acquisition of drug resistance in cancer.163

Brain Targeting

Even if a substance is proven effective in treating brain tumors, neurodegenerative diseases and central nervous system diseases, to the most important challenge is to deliver it to the brain. Effective therapeutic antibodies are being developed to target brain diseases, however, brain delivery approach for these antibodies while maintaining their shape has yet to be developed.164 Nanotechnology is potentially used to protect encapsulated substances. Establishing technologies for transporting nanoparticles to the brain is one of the greatest obstacles in the field of nanomedicine. The major obstacle is the presence of the blood-brain barrier (BBB), which exists between the central nervous system and the blood, and greatly restricts the transport of substances to the brain. Substances circulating in the bloodstream can only pass through the BBB if these are (1) hydrophobic molecules of weight below 450 Da or (2) transported via endogenous transporters present in the BBB.165,166 Therefore, regardless of the type of material used to prepare nanoparticles; it is difficult for them to reach the brain by simply injecting them intravenously in their original state. On the other hand, it has been reported that nonionic surfactant (for example, polysorbate 80)-coated nanoparticles with active targeting function could reach the brain; although the detailed mechanism of transport of nanoparticles into the brain by modification with polysorbate 80 is still unclear. The current prevailing theory is that apolipoprotein adsorption at the polysorbate 80 site of surfactant-coated nanoparticles circulating in the bloodstream that crosses the BBB through receptor-mediated transcytosis (Figure 4C).167,168 The use of nonionic surfactants such as polysorbate 80 may also help nanoparticles to accumulate in the brain for a long time due to their inhibitory effect on P-glycoprotein (Pgp/ABCB1, a mechanism of foreign body efflux in the brain).169,170 Other substances that use this mechanism of brain transport are poly (butyl cyanoacrylate) (PBCA) and PLGA.171 Wilson et al prepared surfactant-coated nanoparticles (rivastigmine-encapsulated PBCA nanoparticles coated with polysorbate 80) and quantitatively evaluated their transport to the brain.172 They administered surfactant-coated nanoparticles to a group of rats via tail vein injection and reported a four-fold increase in the concentration of rivastigmine in the brain one hour after administration compared to the group receiving free drug. Tahara et al prepared surfactant-coated nanoparticles (coumarin-6 encapsulated PLGA nanoparticles coated with polysorbate 80) and quantitatively evaluated their transport to the brain.173 They reported that the surfactant-coated nanoparticles administered to a group of rats via tail vein injection showed a two-fold increase in the concentration of coumarin-6 in the brain one hour after administration, compared to a group of rats being administered bare nanoparticles (without surfactant coating). Furthermore, they reported that the increased transport to the brain was specific only to the nanoparticles coated with polysorbate 80, and similar result was not demonstrated by chitosan or other nonionic surfactants (poloxamer 188). The transport of surfactant-coated nanoparticles into the brain has also been studied using surfactants other than polysorbate 80, such as polyoxyethylene esters of 12-hydroxystearic acid (Solutol® HS15, BASF corporation, Ludwigshafen, Germany) and D-alpha-tocopherol polyethylene glycol 1000 succinate, however, the mechanism of their transport is not clear.174,175 Many studies on brain transport of surfactant-coated nanoparticles have reported only blood concentration and brain accumulation, but it is also important to evaluate the drug accumulation in other non-specific organs. Miyazawa et al prepared surfactant-coated nanoparticles (PLGA nanoparticles encapsulated with β-carotene and coated with polysorbate 80), and quantitatively evaluated their accumulation in the brain and other organs in rats via tail vein administration.176 They reported that the surfactant-coated nanoparticles administered group showed higher drug accumulation in the lungs (350-fold higher concentration compared to the group of bare nanoparticles) than in the brain after one hour of administration. A similar phenomenon has been reported in the study by Tröster et al, who prepared polymethyl methacrylate resin nanoparticles coated with various nonionic surfactants (polysorbates [20, 60, and 80], poloxamers [184, 188, 338, 407, and 908], and polyoxyethylene lauryl ether [Brij 35]) and administered them to rats via tail vein to compare their accumulation in organs over time.177 In their report, compared to the bare nanoparticles, the particles coated with polysorbate 80 had an approximately 11-fold increase in accumulation in the lungs and a nine-fold increase in accumulation in the brain after 30 min of administration. They also reported that approximately half of the particles that had accumulated in the lungs migrated to the liver two hours after administration. Therefore, increasing drug concentrations at the target site of action can enhance the desired therapeutic effect, but significant toxicity may also occur because of the increased drug accumulation in non-specific organs.

While polysorbates and poloxamers have been reported to perform such useful functions, there are concerns about their side effects that cause cell membrane damage and cytotoxicity.178 Recently, potential surfactants other than poloxamer and polysorbate have been discovered for brain targeting. For example, Jeong et al prepared surfactant-coated nanoparticles (PLGA nanoparticles encapsulated with recombinant human erythropoietin [rhEPO] and coated with sodium cholate or polysorbate 80) and evaluated their cellular uptake (human neuroblastoma [SH-SY5Y] cells) and evaluated inhibition rate of glutamate-induced neurotoxicity.179 The results showed that the sodium cholate-coated nanoparticle group was taken up by SH-SY5Y cells and further reduced glutamate-induced neurotoxicity with less toxicity than the polysorbate 80-coated group. They also examined the efficacy of these nanoparticles in vivo experimental stroke model mice and reported that the symptoms were reduced.180 It is expected that a variety of surfactants targeting the brain will be developed in the future. In recent years, the importance of “inter-organ communication,” which considers treatment based on the interaction of the drug with entire body’s organs, and not just the individual organ has been recognized; this concept will also be essential for the development of surfactant-coated nanoparticles.181

Surfactant-Coated Inorganic Nanoparticles in Nanomedicine

Various types of inorganic materials have been used in nanomedicine. In this section, nanoparticles composed of gold and silicon, which have been specially studied, and the applications of inorganic nanoparticles in quantum dots and magnetic resonance imaging (MRI) are mainly discussed (Figure 2B).

Gold Nanoparticles

Gold nanoparticles are one of the most widely used inorganic nanoparticles in nanomedicine due to their ease of preparation, high dispersion, low toxicity, and stability (Figure 2B). And several studies of surfactant-coated gold nanoparticles have been conducted (Table 1). Gold nanoparticles have a long history of research, and the first report on the preparation method by Michael Faraday in 1857 used chloroauric acid solution.182 A typical method for the preparation of gold nanoparticles is the Turkevich method (method of reducing Au3+ and Au+ to Au0, which is the electrical state of nanoparticles, using trisodium citrate), which was reported in 1951 and is still widely used today.183,184 Subsequently, various preparation methods based on chemical reduction of gold ions in the solution have been developed, and gold nanostructures of various shapes (such as nanobowls, nanocages, nanocubes, nanopyramids, nanorods, nanospheres, nanoshells, nanostars, and nanowires) have become available and have been studied and developed into nanomedicine.185–187 Nanoparticles composed of transition elements such as gold have an optical property called surface plasmon resonance (SPR). SPR is a phenomenon in which plasma oscillation on the surface of a transition element generates an electric field around it, and this electric field resonates with light, resulting in strong absorption and scattering of light at a specific wavelength. This property has been used to study the enhanced Raman imaging of transition-element nanoparticles. The absorption maximum of SPR depends on the type of transition element present in the nanoparticles.188 Since enhanced Raman imaging directly detects molecular vibrations, the dynamics of biomolecules in living cells can be observed label-free. This advantage has led to the use of gold nanoparticles for molecular imaging of living cells and elucidation of the functions of biomolecules.189,190 Furthermore, since the extinction coefficient of gold nanoparticles is more than 1000 times higher than that of organic dyes, photothermal treatment using the photothermic properties of SPR is also being investigated.191,192 Furthermore, the photothermic properties of gold nanoparticles leads to a thermoelastic expansion that is converted into a photoacoustic wave with increase in temperature. This property has also been used in research on photoacoustic imaging.193,194 The synthesis of gold nanoparticles is not limited to chemical approaches, but the synthesis of gold nanoparticles using living organisms such as algae, bacteria, and plants (bio-based method) is a topic. In general, the bio-based method is regarded as having the advantages of not using harmful chemicals in the synthesis process and being low cost.195 In addition to the advantages of the bio-based method described above, the use of cultured cell lines to synthesize gold nanoparticles may be less toxic than bio-based method that use bacteria composed of substances that may cause inflammation (surface of synthesized nanoparticle by using bacteria is coated by substances [lipopolysaccharides and endotoxins] derived from bacteria). It is also expected to enable in-situ synthesis of gold nanoparticles inside the tumor for photochemotherapy. Singh et al confirmed in detail the mechanism by which nanostructures of gold nanoparticles are formed by human breast cancer (MCF7) cells from the medium containing gold (III) chloride hydrate.196 They found that the cells were stressed by the presence of low doses of gold ions, resulting in a reversible state of cellular senescence. For this stress, under serum containing medium (Dulbecco’s Modified Eagles Medium (DMEM) supplemented with 10% fetal bovine serum (FBS)), the cells became unstressed state and gold nanoparticles with rounded facets (single and agglomerated) were deposited. On the other hand, in serum-free medium, the cells were in a stressed state and released various secretions outside the cells. Among these secretions, the presence of gold-binding proteins significantly affected the crystal growth of gold nanoparticles, and gold nanoparticles with sharp facets (triangular and hexagonal) were deposited. They further synthesized gold nanoribbons by incubating human breast cancer (MCF7) cells with gold (III) chloride hydrate.197 They confirmed that the gold nanoribbons synthesized by this method had anisotropic and high aspect ratio and showed more efficient energy conversion effect than spherical gold nanoparticles or gold nanorods. The molecular dynamic simulation and supported with experimental photothermal therapy shown useful application of these nanomaterials into nanomedicine for promoting the growth of fibroblast, imaging agent,198 drug carrier with improved bioavailability in vitro199 and in vivo.200 Currently, there are no medical devices for imaging of gold nanoparticles that can be used for clinical applications, and further development of this technology is warranted. On the other hand, some clinical uses of gold nanoparticles themselves include Aurimune® (CYT-6091; CytImmune Sciences, Rockville, MD, USA), which is designed to deliver tumor necrosis factor (TNF-α) to tumor sites, and AuroShell® (Nanospectra Biosciences Inc., Houston, TX), which is designed to enhance the efficacy of near-infrared laser therapy; both of them have been developed as gold nanomedicine products and are in clinical trials.201,202

Silica Nanoparticles

Silica nanoparticles are inorganic solids that are ubiquitously present in the human body (Figure 2B).203 Silanol groups on the surface of silica can be easily modified by targeting ligands such as small molecules, carbohydrates, antibodies, aptamers, proteins, and polymers. Therefore, fluorescent compound-encapsulated silica nanoparticle with active targeting function on its surface has been studied as bioimaging probes and photodynamic therapy for cancer treatment.204,205 The typical methods for the preparation of silica nanoparticles are the Stöber method, which includes adding acid or alkali to an alkoxysilane solution to progress hydrolysis and polycondensation reactions, and the reverse micelle method, which includes adding an alkaline solution and a surfactant in a hydrophobic organic solvent to form a reverse micelle, and then adding an alkoxysilane solution to proceed with the hydrolysis and polycondensation reactions.206,207 Attempts have also been made to reduce the toxicity of highly toxic nanoparticles, such as metals by using the properties of silica. Iqbal et al reported that coating the surface of superparamagnetic iron oxide nanoparticles (SPION), which are used as MRI contrast agents, with silica greatly reduced their cytotoxicity while maintaining their function as MRI contrast agents.208 On the other hand, mesoporous silica nanoparticles composed of porous silica, are relatively new materials whose synthesis was reported by Yanagisawa et al and Mobil Research and Development Corporation in the early 1990s, respectively.209,210 Typical preparation method of mesoporous silica nanoparticles includes preparation of a porous structure by using a supramolecular structure containing surfactant as a template. The size and shape of the pores can be manipulated to some extent, depending on the preparation conditions.211 Mesoporous silica nanoparticles have the following characteristics: (1) pores of 2–30 nm can be prepared with uniform size and distribution, (2) a large pore volume of approximately 1 cm3 g−1 can be achieved, (3) they have a high density of silanol groups on their surfaces, and (4) they have a chemically stable silica framework; these characteristics are likely to be beneficial for their use in nanomedicine.212 Although there have been concerns that the chemical structure of silica tends to become unstable in water and humid environments and that the silanol groups on the silica surface induce hemolysis, but the mesoporous silica nanoparticles with a smaller contact area of silanol groups with red blood cells have been found to be less prone to hemolysis than other silica nanoparticles.213–215 Urata et al prepared an ethylene-bridged silsesquioxane framework containing mesoporous silica nanoparticles to stabilize the skeletal structure and to inhibit the exposure of silanol groups, resulting in decreased hemolysis from 10% to a few percent and further stabilized the skeletal structure compared to ordinary mesoporous silica nanoparticles in vitro.216 Doxorubicin and paclitaxel have been known to be synergistic due to their different anticancer mechanisms. However, it has been difficult to prepare a stable single nanoparticle containing both drugs because of their different physicochemical properties. To solve this problem, Yan et al reported the preparation of mesoporous silica nanoparticles with doxorubicin being present inside the pores, and a derivative of paclitaxel to the surface of the particles and further coated the surface with polystyrene sulfonate.217 The prepared nanoparticles successfully released both the drugs according to the pH and redox status of the cancer cells in vitro. Although research on silica-based nanomedicine continues to make great progress, one of the reasons why it has not yet reached clinical trials may be its potential toxicity, which has not been dispelled. While the toxicity of crystalline silica particles due to occupational exposure is widely recognized, the potential toxicity of silica is considered proportional to its crystallinity, and therefore it is believed that amorphous silica particles are low in toxicity.218 Currently, epidemiological studies have not yet reached to a clear conclusion, and the safety of silica-based materials needs to be further confirmed.219 In recent years, a field of nanomedicine called “nanotheranostics” has been developed for the diagnosis and treatment of diseases at the same time, and the development of bio-imaging probes is under intense investigation in this field.220–222 The fluorescence imaging technology using quantum dots, which enables to visualize the behavior of individual cells in vivo and to treat them at the same time, has been attracting attention (Figure 2B).223 Quantum dots, which are colloids of semiconducting nanoparticles approximately 2–50 nm in size, have fluorescent properties compared to fluorophores: negligible fluorescence photobleaching in response to the excitation light, a broader excitation spectrum, and a sharper emission peak.224,225 Quantum dots with large particle sizes have a small band gap and emit red light, while quantum dots with small particle sizes emit blue light owing to their quantum confinement effect. Therefore, the light absorption and fluorescence emission wavelengths are shifted to the shorter wavelengths with higher energy as the particle size decreases. Due to these fluorescent properties, quantum dots can be used with a single light source to simultaneously excite and visualize target cells labeled with various types of quantum dots. The use of quantum dots has enabled imaging that was difficult to achieve with fluorophores including cytometric imaging,226 lymph node mapping,227,228 imaging of cancer stem cells,229 and imaging of circulating tumor cells.230 However, since quantum dots are composed of semiconductor materials, side effects of heavy metals and their residues (selenium, cadmium, and lead) in living organisms are a major concern.231,232 The shape of the nanoparticles is also related to cytotoxicity as shown in a study by Yamamoto et al that dendritic titanium dioxide particles with dendritic shape have higher cytotoxicity than spindle and spherical shapes.233 If quantum dots are to be used clinically in the future, these potential risks will need to be eliminated in advance. Recently, research and development of quantum dots composed of less toxic carbon, silicon, and germanium has initiated.234–236 Shen et al prepared surfactant-coated nanoparticles (quantum dots composed of silicon covered with poloxamer 407) and determined whether they could be used for the imaging of mitochondria in human umbilical vein endothelial cells (HUVECs) using confocal microscopy.237 As a result, they reported that the MitoTracker® (commonly used fluorophore for fluorescent staining of mitochondria) faded in 80 seconds, whereas surfactant-coated nanoparticles accumulated in the mitochondria with low toxicity for further use in living cells, and also maintained nearly constant fluorescence intensity for 30 min.

Other Inorganic Nanoparticles

Nanomedicine is also used in MRI, which is an important imaging technique in contemporary medicine. MRI is used clinically to observe signals of hydrogen ions (1H) contained in water molecules (H2O), and adipose tissues (CH, CH2, and CH3). The magnetization of hydrogen ions in a static magnetic field is excited by the magnetic resonance (MR) phenomenon when irradiated with radiofrequency magnetic waves (radiofrequency [RF] pulses). MRI detects the relaxation time for these excited hydrogen ions to return to the ground state. The T1 relaxation time of hydrogen ions is observed to be greatly shortened by the presence of surrounding transition elements (Cr2+, Cr3+, Mn2+, Mn3+, Fe2+, and Fe3+) and lanthanides (Gd3+ and Dy3+), and MRI contrast agent containing nanoparticles composed of these elements have been studied (Figure 2B).238,239 For example, ferucarbotran (Resovist®, Bayer Healthcare, Leverkusen, Germany), ferumoxides (Feridex®, Bayer Healthcare, Leverkusen, Germany), erumoxtran-10 (Combidex®, AMAG Pharma, Waltham, MA), and NC100150 (Clariscan®, Nycomed, Zürich, Switzerland), which are composed of SPION, have been used in clinical practice as MRI contrast agent nanoparticles.240 On the other hand, metal ions in MRI contrast agent nanoparticles have the potential risk of disrupting the redox balance in vivo by reacting with hydrogen peroxide to produce reactive oxygen species (ROS), and oxidizing vitamins and proteins, which are antioxidants present in the body; this leads to the progression and development of the disease.241 The accumulation of inorganic nanoparticles in monocytes, macrophages, and tissues can also cause inflammation; nanoparticles such as silica, gold, silver, carbon, iron, zinc, and titanium, have been reported to induce the production of various proinflammatory cytokines (interleukin [IL]-1β, IL-6, IL-12, IL-23, and TNF-α), and ROS associated with classically activated (M1) macrophages.242 These pro-inflammatory cytokines increase the expression of P-glycoprotein in various organs in vivo, and prevent likely functions of the nanoparticles.243,244 Radomski et al also reported that carbon nanoparticles interact with platelets and vascular endothelial cells, resulting in localized inflammation in vivo.245 Further studies are needed to avoid the potential health risks associated with such inorganic nanoparticles.

Other Nanostructures in Nanomedicine

This review focuses on “nanoparticles” among various nanostructures (carbon nanotubes, dendrimers, liposomes, micelles, nanographenes, nanorobots, and nanosheets) used in the field of nanomedicine. Properties and applications of other nanostructure that could not be presented in this review have been reviewed in detail in other reports.246–250

Application of Surfactant-Coated Nanoparticles in Food Nanotechnology

Food Nanotechnology

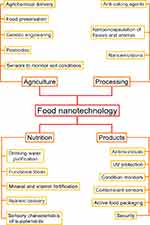

The development in the field of nanotechnology has been remarkable, and interest in its application in the global food industry has increased greatly in recent years due to its potential to add new properties and functions to existing food products. The international symposium “Nanotechnology Research: Applications in Nutritional Sciences” was held at Experimental Biology 2009, focusing on the application of nanotechnology to food and nutrition, and this field was widely recognized.251 Although a definition of nano-based technologies in the field of food and nutrition has not yet been established, the application of nanoscale material properties to the food and nutrition industry is generally named as “food nanotechnology”.252–254 Currently, there are no established global rules regarding the applications of food nanotechnology, however, the Organization for Economic Cooperation and Development (OECD) launched a sponsorship program for testing of nanomaterials in 2007, and the FDA issued four guidance documents on the use of nanotechnology in animal products, cosmetics, food, and other products in 2014–2015.253 In the field of food nanotechnology, the approach of nanoparticles is considered to have the potential to be applied in various technologies, such as pesticides,255 antimicrobial,256 anti-solidification,257 plant genetic engineering,258 detection of foodborne pathogens,259 food processing,260 development of functional foods,261 purification of drinking water,262 extension of food preservation,263 and texture improvement252–254,264,265 (Figure 6). Surfactant-coated nanoparticles have been widely used in the field of food nanotechnology. Recent progress of surfactant-coated nanoparticles in this field is summarized in Table 2. Surfactant-coated organic and inorganic nanoparticles in food nanotechnology will be discussed separately in the following sections.

|  |  |  |  |  |  |  |  |

Table 2 Summary of Surfactant-Coated Nanoparticles Used in the Field of Food Nanotechnology |

|

Figure 6 The potential applications of food nanotechnology. Notes: Data from Martirosyan.265 |

Surfactant-Coated Organic Nanoparticles in Food Nanotechnology

Smart Food